Novel formaldehyde removal material and processing technology thereof

A processing technology, a formaldehyde-removing technology, applied in the field of new formaldehyde-removing materials and its processing technology, can solve the problems of high production cost, difficult to find raw materials, poor effect of formaldehyde-removing materials, etc., to improve practicability, improve removal effect, and improve adsorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A new type of formaldehyde-removing material. The formula includes: sepiolite, activated carbon, Yeguangni nano-live ore, shell powder and bentonite. The parts by weight of each component are: 10-15 parts of sepiolite, 0.5-1 1 part of activated carbon, 0.5-1 part of Yeguangni nanometer live ore, 3-5 parts of shell powder and 3-5 parts of bentonite.

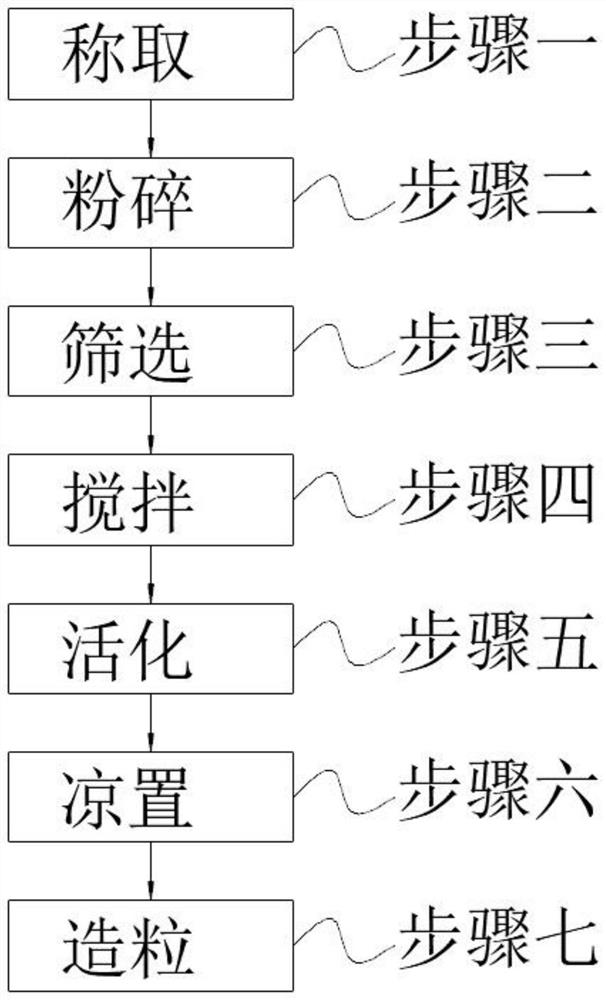

[0025] A processing technology for a novel formaldehyde-removing material, comprising the following steps: Step 1, weighing; Step 2, crushing; Step 3, screening; Step 4, stirring; Step 5, activation; Step 6, cooling; Step 7, making grain;

[0026] Wherein in the above-mentioned step 1, according to the parts by weight of each component, take respectively 10 parts of sepiolite, 0.5 part of activated carbon, 0.5 part of Ye Guangni nano live ore, 3 parts of shell powder and 3 parts of bentonite spare;

[0027] Wherein in the above step two, the sepiolite weighed in step one is placed in a crusher for crushing, and then the c...

Embodiment 2

[0034] A new type of formaldehyde-removing material. The formula includes: sepiolite, activated carbon, Yeguangni nano-live ore, shell powder and bentonite. The parts by weight of each component are: 10-15 parts of sepiolite, 0.5-1 1 part of activated carbon, 0.5-1 part of Yeguangni nanometer live ore, 3-5 parts of shell powder and 3-5 parts of bentonite.

[0035] A processing technology for a novel formaldehyde-removing material, comprising the following steps: Step 1, weighing; Step 2, crushing; Step 3, screening; Step 4, stirring; Step 5, activation; Step 6, cooling; Step 7, making grain;

[0036] Wherein in the above-mentioned step 1, according to the parts by weight of each component, take respectively 15 parts of sepiolite, 1 part of activated carbon, 1 part of Ye Guangni nano live ore, 5 parts of shell powder and 5 parts of bentonite spare;

[0037] Wherein in the above step two, the sepiolite weighed in step one is placed in a crusher for crushing, and then the crush...

Embodiment 3

[0044] A new type of formaldehyde-removing material. The formula includes: sepiolite, activated carbon, Yeguangni nano-live ore, shell powder and bentonite. The parts by weight of each component are: 10-15 parts of sepiolite, 0.5-1 1 part of activated carbon, 0.5-1 part of Yeguangni nanometer live ore, 3-5 parts of shell powder and 3-5 parts of bentonite.

[0045] A processing technology for a novel formaldehyde-removing material, comprising the following steps: Step 1, weighing; Step 2, crushing; Step 3, screening; Step 4, stirring; Step 5, activation; Step 6, cooling; Step 7, making grain;

[0046] Wherein in the above-mentioned step 1, according to the parts by weight of each component, take respectively 12 parts of sepiolite, 0.8 part of activated carbon, 0.8 part of Ye Guangni nano live ore, 4 parts of shell powder and 4 parts of bentonite spare;

[0047] Wherein in the above step two, the sepiolite weighed in step one is placed in a crusher for crushing, and then the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com