Glove processing blow mold with cooling function

A blow molding mold and mold technology, which is applied to the field of blow molding molds for glove processing, can solve the problems of low cooling efficiency, inability to use gas, harm to people around, and achieve the effects of improving the efficiency of cooling and improving the efficiency of demolding.

Pending Publication Date: 2022-06-21

南通众辰模具有限公司

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] After the glove model is made, it needs to be cooled before it can be demolded. One of the current cooling methods is natural cooling, which has low cooling efficiency and is not conducive to the rapid cooling of the blow mold. The other is to use cooling liquid or The fan blades cool down the blow mold. This method requires the operation of an additional cooling device, resulting in increased energy consumption, and the blow molding machine is inserted into the mold through the blow molding port. It will be discharged through the blow molding port. On the one hand, the discharged gas is hot and easy to cause harm to people around. On the other hand, the discharged gas cannot be used, resulting in a waste of gas. Blow mold for gloves processing with cooling function

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

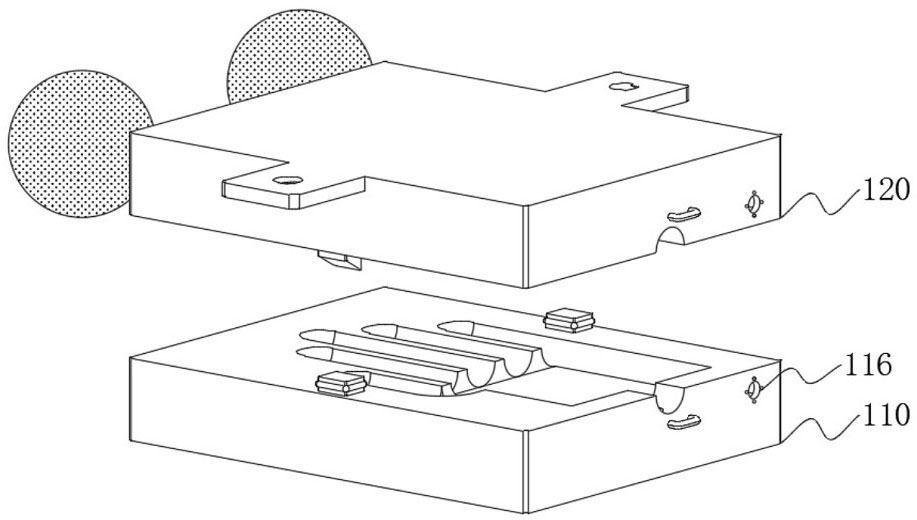

Login to View More Abstract

The invention relates to a blow molding mold, in particular to a blow molding mold with a cooling function for glove processing. The blowing mold with the cooling function for glove processing comprises a mold body and a cooling device arranged in the mold body, the mold body comprises a mold bottom shell and a mold top shell, in the blowing mold with the cooling function for glove processing, redundant gas in a model groove can be guided into a cooling cavity through a flow guide assembly, so that the gas is reasonably utilized, and the cooling effect is improved. The problems that according to an existing cooling method, natural cooling is adopted, cooling liquid or fan blades are used for cooling a blow molding mold, a blow molding machine is inserted into the mold through a blow molding opening, when plastic billets are subjected to blow molding, part of gas can be exhausted through the blow molding opening in the blow molding process, and on one hand, the blow molding efficiency is greatly improved are solved. And on the other hand, the exhausted gas is hot and easily causes harm to surrounding people, and on the other hand, the exhausted gas cannot be utilized, so that gas waste is caused.

Description

technical field [0001] The invention relates to a blow molding mold, in particular to a blow molding mold with cooling function for processing gloves. Background technique [0002] Gloves are hand warming or labor protection articles, and are also used for decoration. Gloves are a very special thing. They were not created for practicality at the beginning, but in modern times, they became necessary for heat preservation in cold areas, or medical antibacterial and industrial protective products. There are many types of gloves, such as cotton cloth Gloves, rubber gloves and latex gloves, etc. [0003] Latex gloves need to use glove molds in the production process, and there are many ways to make glove molds. The representative method is blow molding. The plastic gizzard is formed by preheating the raw materials, and then the plastic girdle is blown into the mold by a blow molding machine. To form a glove model in a blow mold. [0004] After the glove model is made, it needs...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C49/64B29C49/48B29C49/56B29C33/40

CPCB29C49/4823B29C2049/4825B29C49/70B29C33/04B29C33/046B29L2031/4864Y02P70/10

Inventor 钱有良季斌斌汪涛钱雨轩吴益峰顾小星

Owner 南通众辰模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com