Building waste recovery equipment based on high-rise building construction

A technology for construction waste and high-rise buildings. It is applied in the direction of garbage collection, construction, and building components. It can solve problems such as heavy burden on elevator traction devices, time-consuming and laborious packaging of garbage, and shaking of elevator cars, so as to save workers' physical strength and work efficiency. High, the effect of avoiding the body shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

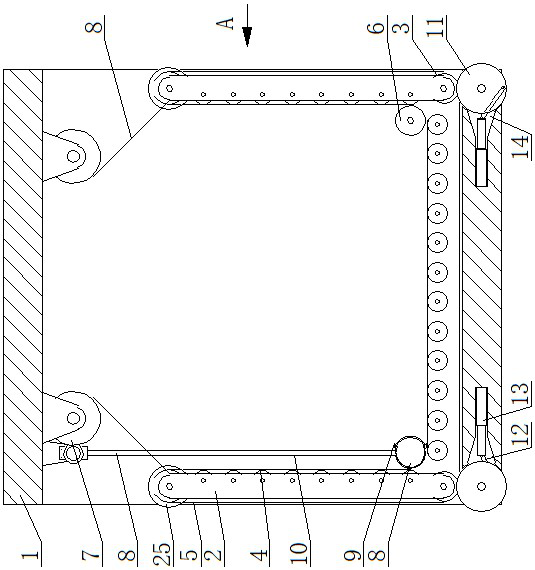

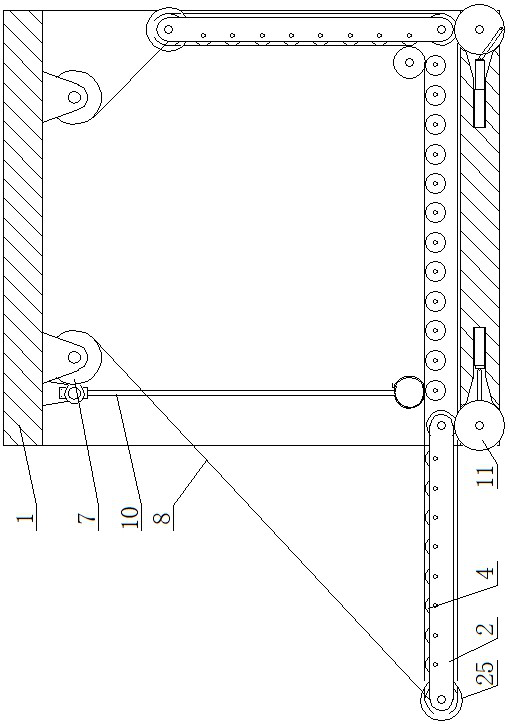

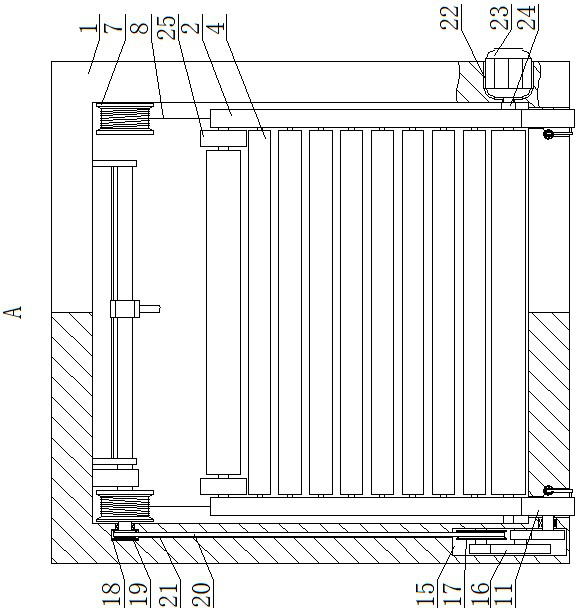

[0014] A kind of construction waste recovery equipment based on high-rise building construction, as shown in the figure, includes a box body 1 with openings on both sides of the box body 1, and is characterized in that two swing arms 2 are installed on both sides of the box body 1 for rotation, The swing arm 2 can be completely located in the box body 1, and one end of the swing arm 2 is rotatably connected to the front and back of the inner wall of the box body 1, and two rotating rollers 3 and several support rollers 4 are arranged between the two swing arms 2 on the same side , two rotating rollers 3 are distributed on the end of the swing arm 2 one up and down, the rotating roller 3 and the idler roller 4 are connected to the swing arm 2 in rotation, the rotating connection point of the swing arm 2 and the box body 1 is connected with the rotating roller located below 3 are coaxial, all the rotating rollers 3 are connected by a transmission belt 5, the idler rollers 4 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com