Control method of feeding device for washing equipment

A technology for feeding devices and washing equipment, applied to washing devices, washing machine control devices, applications, etc., can solve problems such as complex feeding process, waste of laundry treatment agents, wrong injection of laundry treatment agents, etc., to achieve uniform distribution and control logic Simple, easily evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a control method for an injecting device of a washing device, which is used for injecting a laundry treatment agent into the washing device. The washing equipment includes, but is not limited to, a pulsator washing machine, a drum washing machine and an all-in-one washing and drying machine.

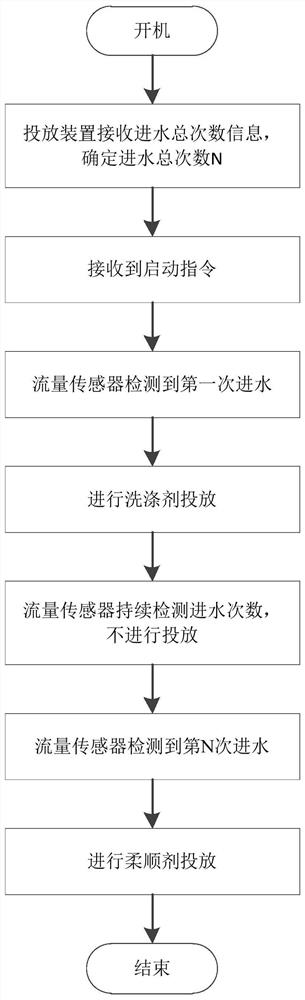

[0058] The feeding device described in this embodiment includes a water inlet end connected to an external water source, a water outlet end connected to the water inlet valve of the washing equipment, and a flow sensor for detecting the water inlet amount of the washing equipment. The injecting device determines whether to inject the laundry treatment agent according to the number of times of water inflow of the washing equipment detected by the flow sensor.

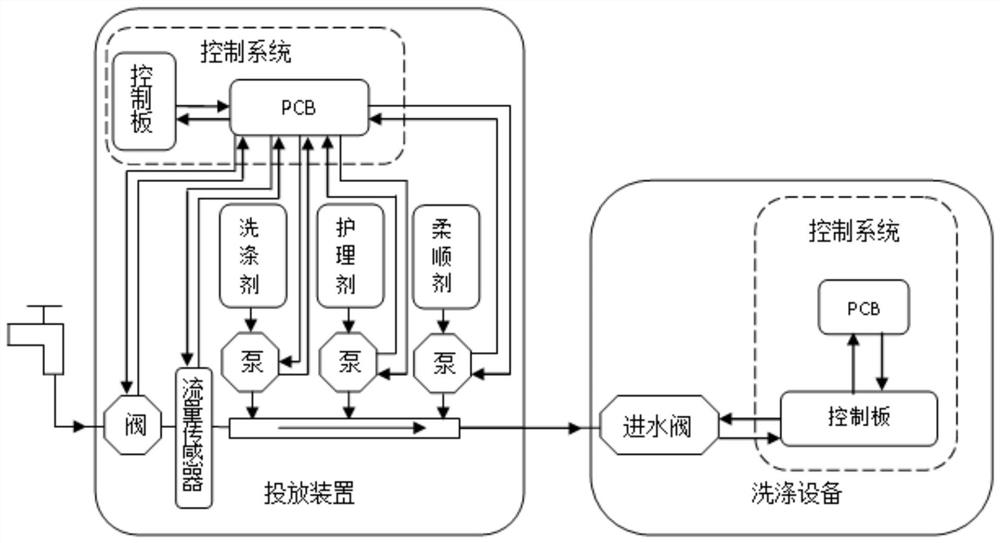

[0059] like figure 1 As shown, in this embodiment, the throwing device and the washing device respectively have independent control systems. Specifically, the injecting device includes a wat...

Embodiment 2

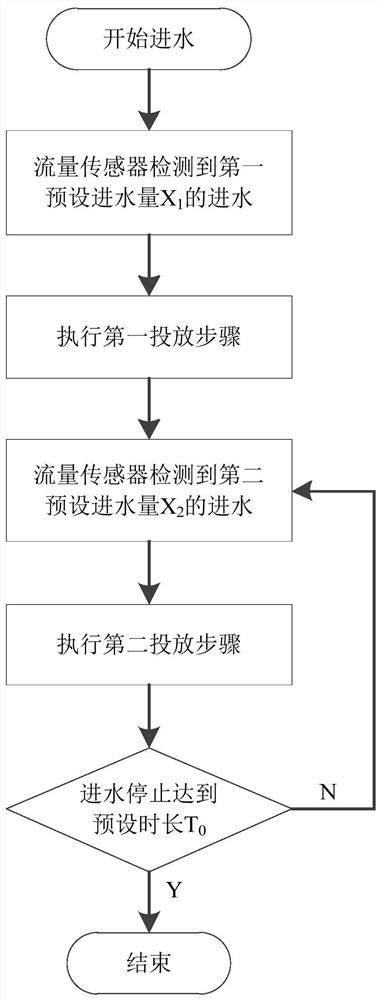

[0083] like Figure 4 As shown, the difference between this embodiment and the above-mentioned first embodiment is that the delivery device receives the delivery process information set by the user, and performs the delivery of the laundry treatment agent according to the delivery process information.

[0084] Specifically, the dispensing device includes at least two liquid storage chambers containing different types of laundry treatment agents.

[0085] The injecting device receives the injecting process information set by the user, and the injecting process information includes whether the laundry treatment agent is injected in each water inflow during the current operation of the washing device, and the type of the laundry treatment agent to be injected.

[0086] After the injection device receives the start instruction, when the flow sensor detects each water inflow of the washing equipment, the injection device injects the laundry treatment agent according to the injectio...

Embodiment 3

[0096] like Figure 5 As shown, the difference between this embodiment and the above-mentioned first embodiment is that the feeding device receives the washing program information selected by the user, and retrieves the feeding program corresponding to the selected washing program to do the laundry treatment agent.

[0097] Specifically, the washing equipment has a plurality of washing programs, the putting device has a plurality of putting programs, and the multiple putting programs of the putting device are in one-to-one correspondence with the multiple washing programs of the washing equipment. The putting procedure includes whether to put the laundry treatment agent in each time the water enters when the washing device runs the corresponding washing procedure.

[0098] The feeding device receives the washing program information selected by the user, and determines the washing program of the current operation of the washing equipment.

[0099] After receiving the start ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com