Inter-axis distance measurer and image forming apparatus

An inter-axis distance and measuring device technology, which is applied in the direction of measuring devices, image communication, and electrical devices, etc., can solve the problems of difficulty in measuring the distance between axes, lack of sufficient space, and inability to follow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

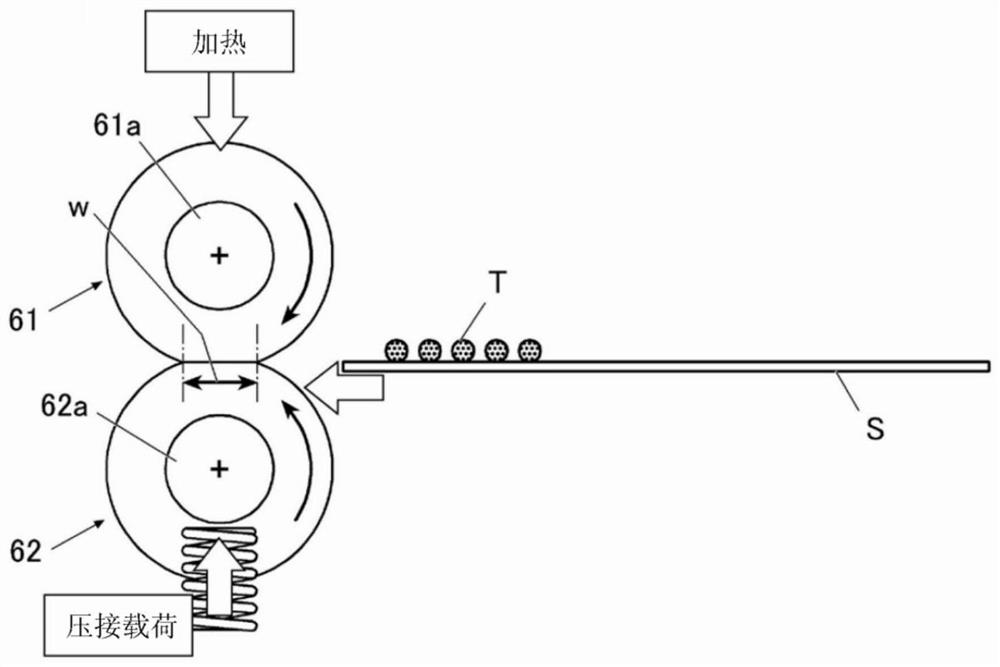

[0063] Figure 4 Two axes 61a, 62a of the measurement object are shown. One shaft 61 a is a core material constituting the shaft of the upper roll 61 . The other shaft 62a is a core material constituting the shaft of the lower roll 62 . like Figure 4 As shown, the distance between the two axes 61a and 62a is set as the measurement object, and the inter-axis distance measuring device 90 is set in the state at the time of measurement.

[0064] The inter-axis distance measuring instrument 90 is an inter-axis distance measuring instrument for measuring the distance between two axes or the displacement amount of the distance, and includes a first measuring head 91, a second measuring head 92, a linear moving mechanism (moving mechanism) 93, and Measurement unit (94).

[0065] The first measuring head 91 abuts on the peripheral surface 61c of one of the two shafts 61a and 62a during measurement, and serves as one measurement reference.

[0066] The second measurement head 92 c...

no. 2 approach

[0094] Hereinafter, an embodiment of a modified example based on the above-described first embodiment will be described. The same parts are denoted by the same reference numerals, and descriptions thereof are omitted.

[0095] Here, refer to Figure 8 The second embodiment will be described.

[0096] exist Figure 8 In the inter-shaft distance measuring device 90B shown, in the first measuring head 91 in contact with the peripheral surface 61c at two positions 91a, 91b, rolling bearings 91c, 91d are provided at each of the two positions 91a, 91b . As described above, the first measurement head 91 is in contact with the peripheral surface 61c of the shaft 61a at the two positions 91a and 91b. The abutting members are used as rolling bearings 91c and 91d.

[0097] exist Figure 8 In the inter-shaft distance measuring device 90B shown, the second measuring head 92 in contact with the peripheral surface 62c at two positions 92a and 92b is also provided with a rolling bearing...

no. 3 approach

[0100] Next, refer to Figure 9 A third embodiment will be described.

[0101] exist Figure 9 The shown inter-axis distance measuring device 90C includes an elastic connecting portion 62S for connecting either one of the first measuring head 91 and the second measuring head 92 (in the present embodiment, the second measuring head 92). The head 92) is fixed to the support frame 62F of the shaft 62a with which the one measurement head 92 is in contact with the measurement head 92 being pressed against the shaft 62a by the elastic force.

[0102]Approaching and separating operations of the two shafts 61a and 62a include a crimping and deviating stroke during operation of the image forming apparatus 1, and a stroke in which separation exceeds the maximum distance of the crimping and deviating stroke for maintenance and the like (hereinafter referred to as a stroke). "Open Stroke"). The crimping and deviating strokes are ranges that vary according to the driving force. The lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com