Automatic cotton fiber detection equipment

An automatic detection, cotton fiber technology, applied in the direction of measuring devices, material inspection products, textile testing, etc., can solve the problems of low efficiency, long operation time, detection errors, etc., and achieve the effect of automatic design

Active Publication Date: 2022-06-21

UNIV OF SCI & TECH OF CHINA +1

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

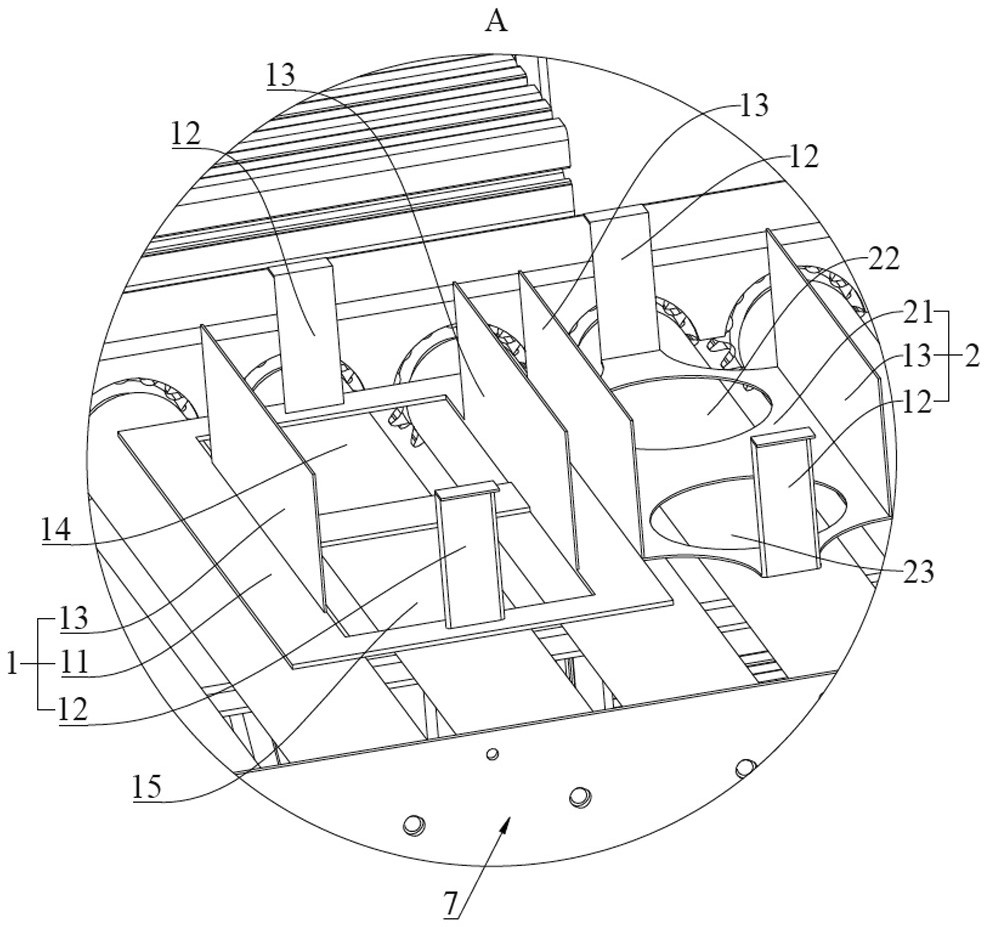

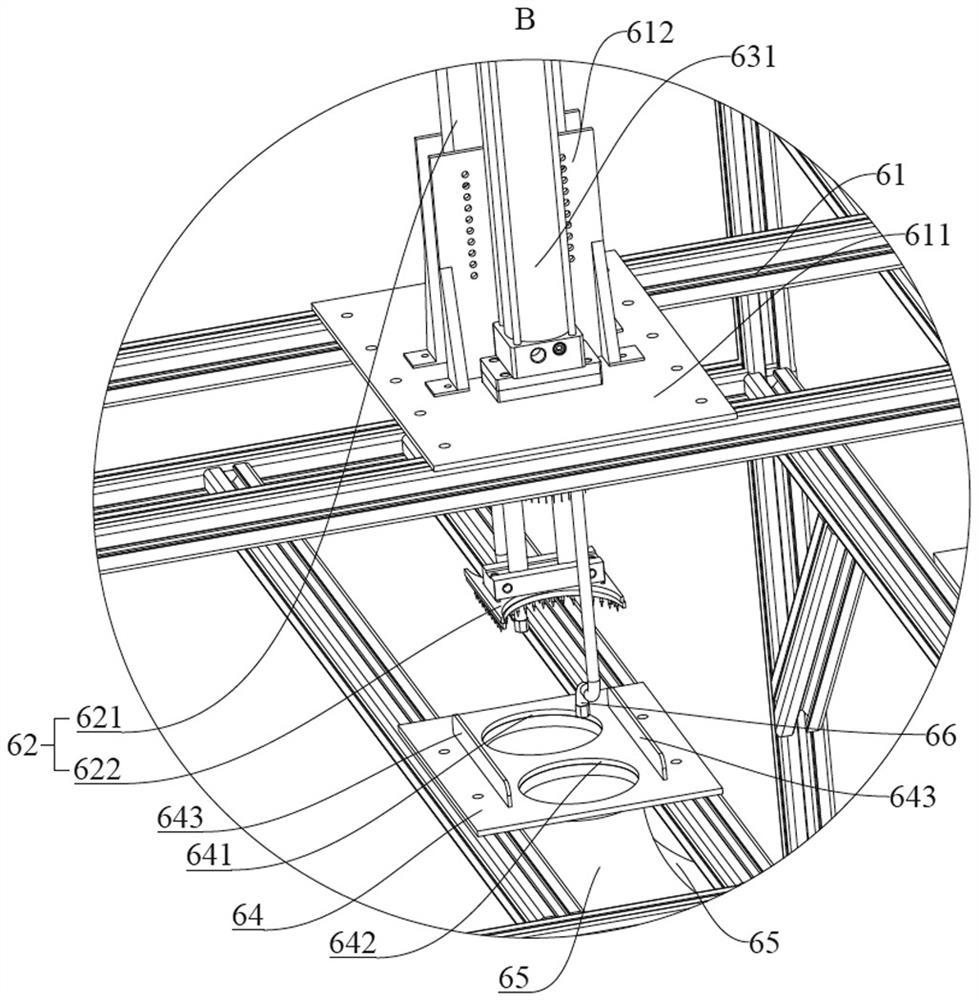

[0006] The beneficial effects of the present invention are: the cotton fiber automatic detection equipment provided by the present invention can realize the automatic detection of the color, impurity, length and strength of the cotton fiber, aiming at the current The manual operation of cotton fiber detection has the disadvantages of high work intensity, long operation time, detection errors caused by easy fatigue operation, occupational diseases caused by fiber dust, low use efficiency and insufficient benefits, etc. Set up the first sample box and the second sample box The cotton fiber sample is subpackaged, and the first sample box is grabbed by the grabbing mechanism to the color and impurity detection device, and the color and impurity detection device passes through the color detection port of the first sample box and the The impurity detection port is used to detect the cotton fiber sample; the second sample box is grabbed by the grabbing mechanism to the splitting mechanism, and the splitting mechanism will be located at the length detection port and the strength detection port of the second sample box. The cotton fiber samples are disassembled and transported to the length and strength detection device for detection; the automatic design of the cotton fiber detection process is realized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0039] The above description is only an embodiment of the present invention, and does not limit the patent scope of the present invention. All equivalent transformations made by using the description of the present invention and the contents of the accompanying drawings, or directly or indirectly used in related technical fields, are all included in the same principle. Within the scope of patent protection of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

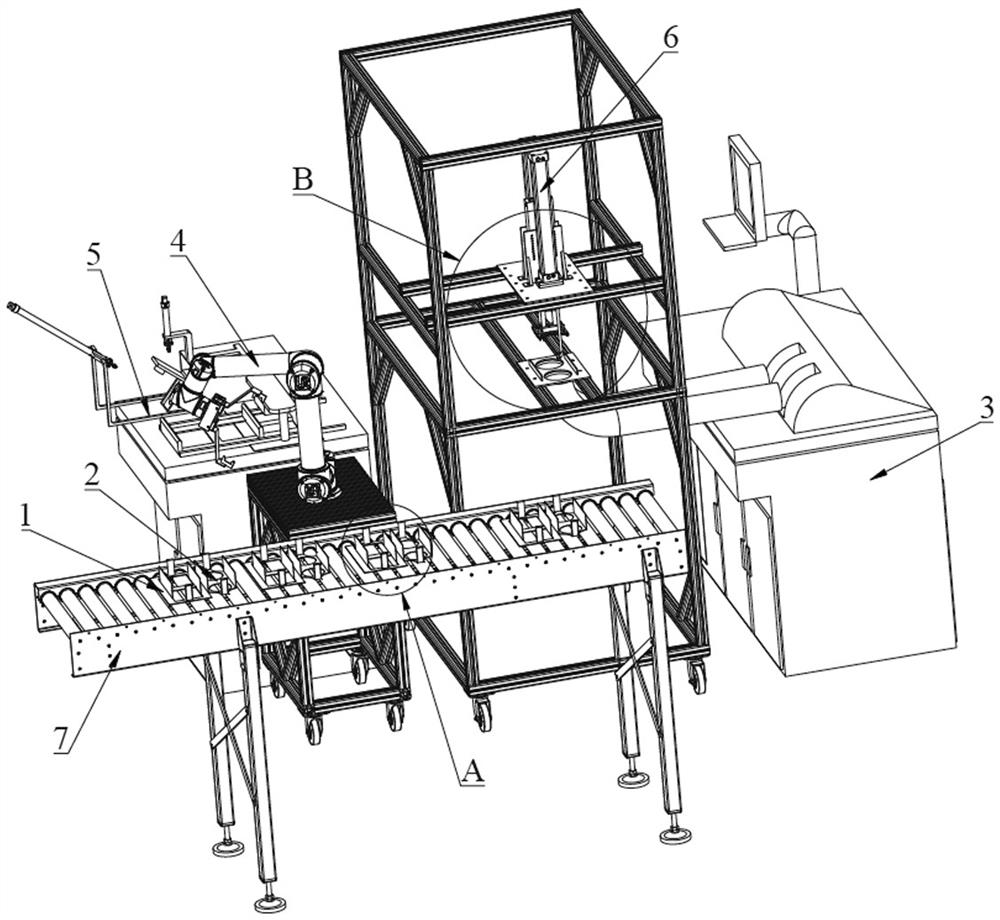

The invention discloses automatic cotton fiber detection equipment which comprises a color and impurity detection device, a grabbing mechanism, a splitting mechanism, a length and strength detection device, a first sample box and a second sample box, and the first sample box and the second sample box are both used for containing cotton fiber samples. A color detection port and an impurity detection port for exposing cotton fiber samples are formed in the bottom of the first sample box, and a length detection port and a strength detection port for exposing the cotton fiber samples are formed in the bottom of the second sample box; the first sample box is grabbed to the color and impurity detection device through the grabbing mechanism, and the color and impurity detection device detects a cotton fiber sample through a color detection opening and an impurity detection opening of the first sample box; the second sample box is grabbed to the splitting mechanism through the grabbing mechanism, and the splitting mechanism is used for splitting the cotton fiber samples located at the length detection port and the strength detection port and conveying the cotton fiber samples to the length and strength detection device for detection; and automatic detection of the cotton fiber sample is realized.

Description

technical field [0001] The invention relates to the technical field of cotton fiber detection equipment, in particular to an automatic cotton fiber detection equipment. Background technique [0002] At present, cotton occupies an important economic position in the gross national product, and the quality of cotton fiber has a great impact on the cotton textile industry. Therefore, accurate and rapid quality inspection of cotton fiber is of great significance to the cotton textile industry. In the early days, the inspection of cotton fibers at home and abroad was a sensory inspection method, which combined visual inspection, hand pulling, and hand feeling, that is, according to the appearance and color type of cotton, the strength of the pulling force when the fiber is broken, and the elasticity when grasping the cotton. To judge to identify quality characteristics such as cotton appearance, moisture, maturity, etc. The sensory inspection method requires professional training...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N33/36G01N21/25G01B21/02B25J9/00B25J15/02

CPCG01N33/36G01N21/25G01B21/02B25J9/00B25J15/02Y02W30/66

Inventor 金虎张世武鲍丙亮王琛王二龙吴勇军曹童发陈文兵褚德杨

Owner UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com