Waste gas treatment device of thermal power plant

A waste gas treatment device and thermal power plant technology, applied in the direction of combined devices, transportation and packaging, separation methods, etc., can solve the problems of wasting water resources, low filtration efficiency, easy clogging of filter nets, etc., and achieve the goal of preventing clogging and improving filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

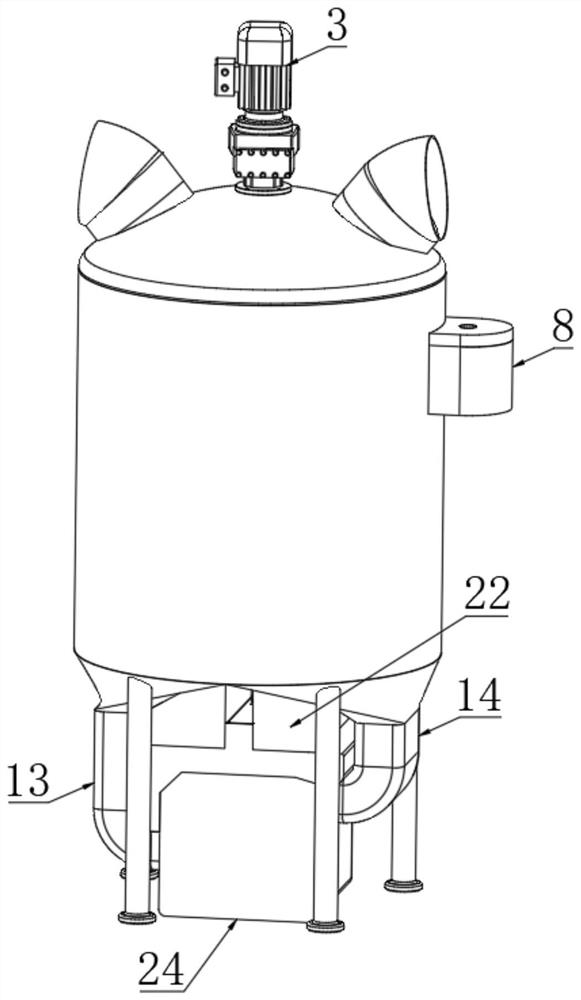

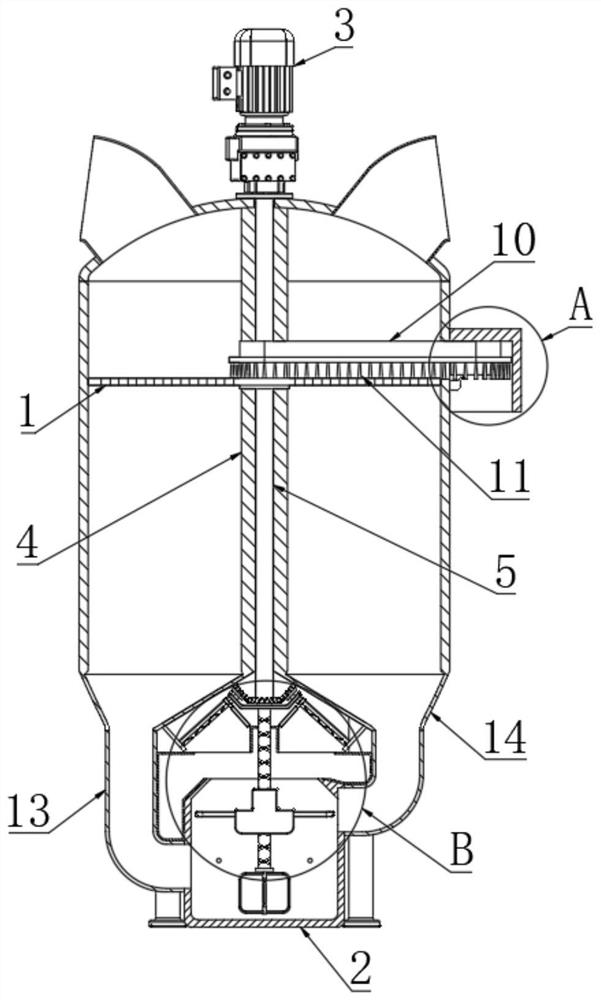

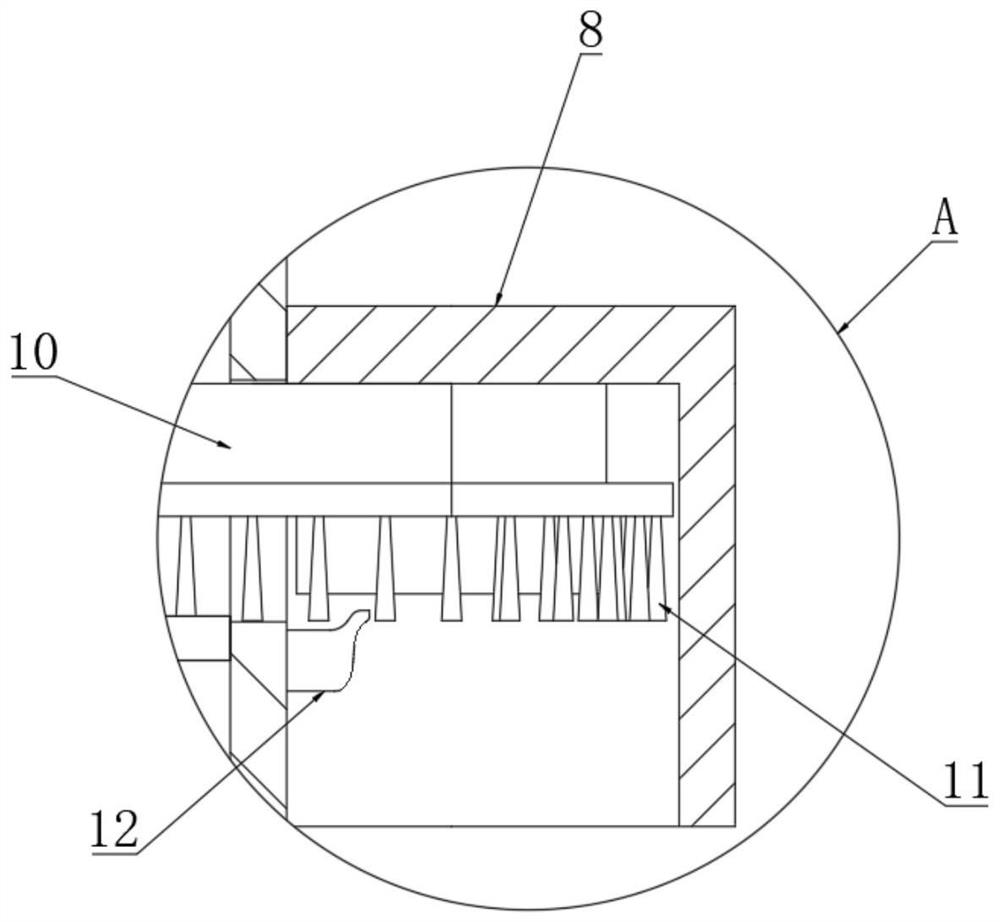

[0032] like figure 1 and figure 2As shown, the embodiment of the present invention provides an exhaust gas treatment device of a thermal power plant, including an exhaust gas treatment tank, the top end of the exhaust gas treatment tank is respectively provided with an air inlet and an air outlet, and the bottom end of the exhaust gas treatment tank is provided with a support leg , a motor 3 is installed on the top of the exhaust gas treatment tank, a partition 4 is arranged inside the exhaust gas treatment tank, and a rotating shaft 5 is arranged inside the partition 4 corresponding to the axial position of the exhaust gas treatment tank, and the output end of the motor 3 passes through the exhaust gas treatment tank. The top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com