Cutting tool

A technology for cutting tools and cutting parts, applied in manufacturing tools, metal processing equipment, metal sawing equipment, etc., can solve the problems of polluting the working environment, affecting the cutting accuracy, and affecting the user's sight of operation, so as to avoid environmental pollution and improve utilization. rate, the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

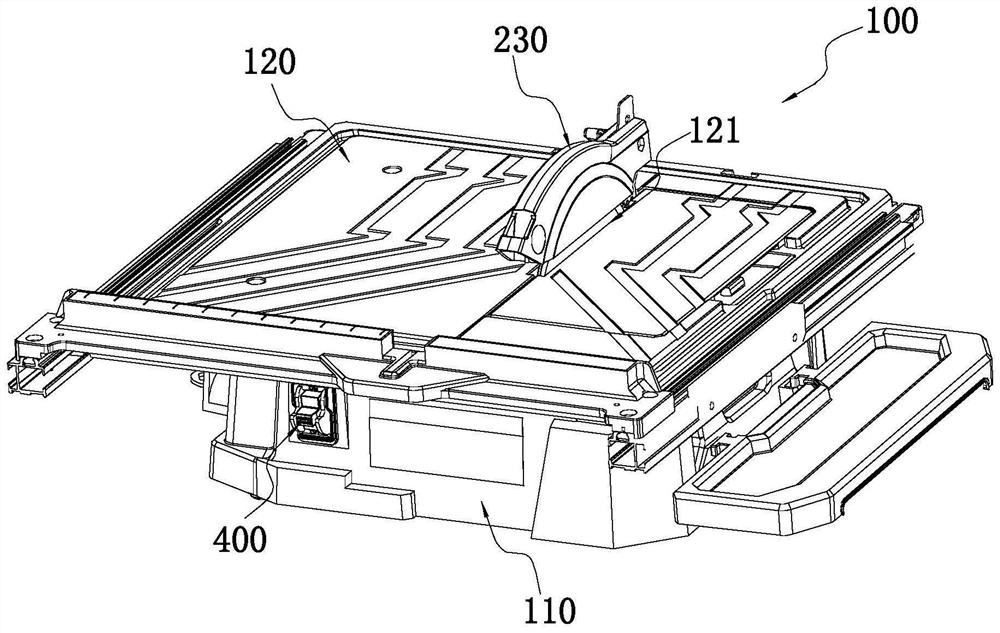

[0062] like figure 1As shown, it is a cutting tool 100 of the present invention, and the cutting tool 100 is a tile cutting machine, which can be used for cutting tiles, marble, granite and the like. The cutting tool 100 includes a base 110, an operating table 120 and a cutting mechanism.

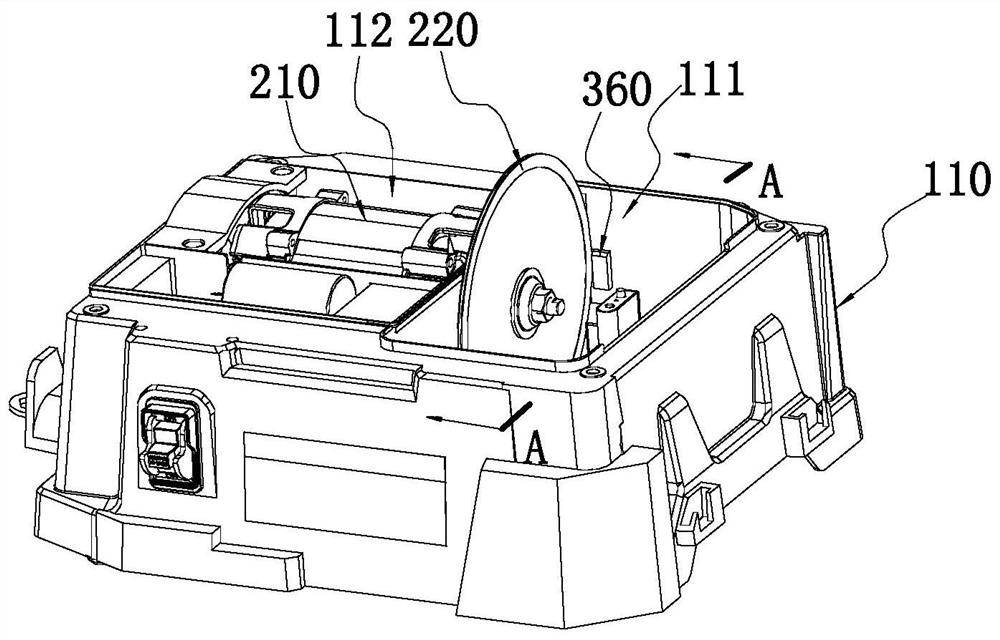

[0063] like Figure 1-Figure 2 As shown, the cutting tool 100 further includes a switch assembly 400 and a control assembly (not shown in the figure), wherein the control assembly is used to control the operation of the cutting tool 100, and the switch assembly 400 is respectively connected with the driving member 210 and the control assembly to control the driving 210 start and stop.

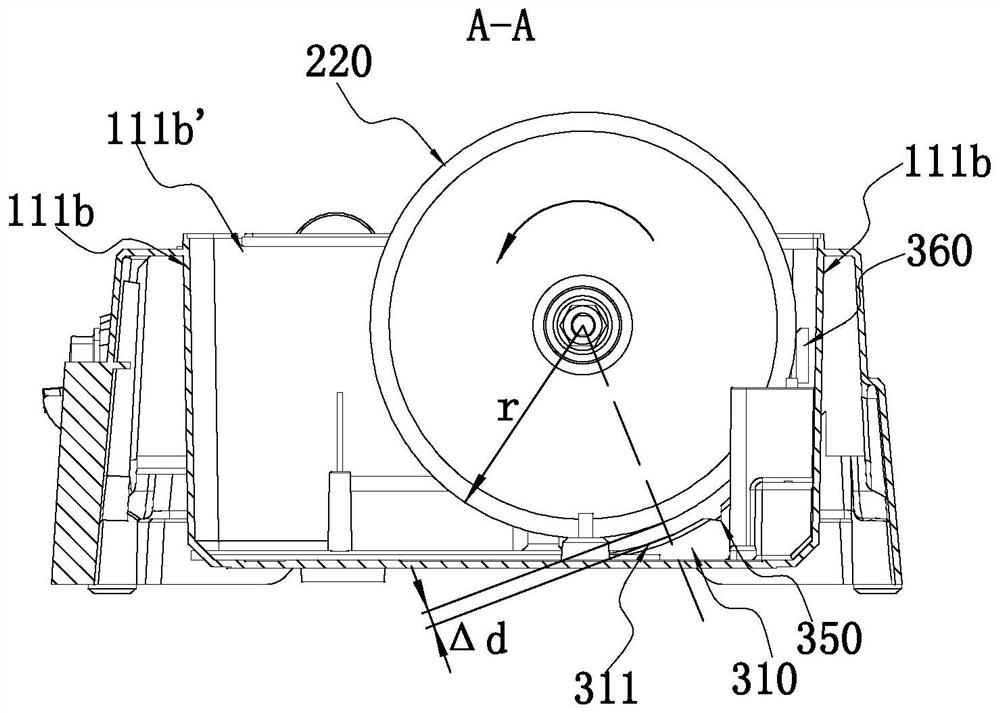

[0064] The base 110 can be placed on the bottom surface or other workbenches, such as figure 2 As shown, the base 110 is provided with an installation chamber 112 and a fluid chamber 111, wherein the fluid chamber 111 is used to hold the cooling liquid, and the bottom of the fluid chamber 111 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com