Corrosion-resistant oil casing and preparation method thereof

A technology for corroding oil and casing, applied in casing, chemical instruments and methods, drill pipe, etc., can solve problems such as casing damage, and achieve the effect of easy purchase and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

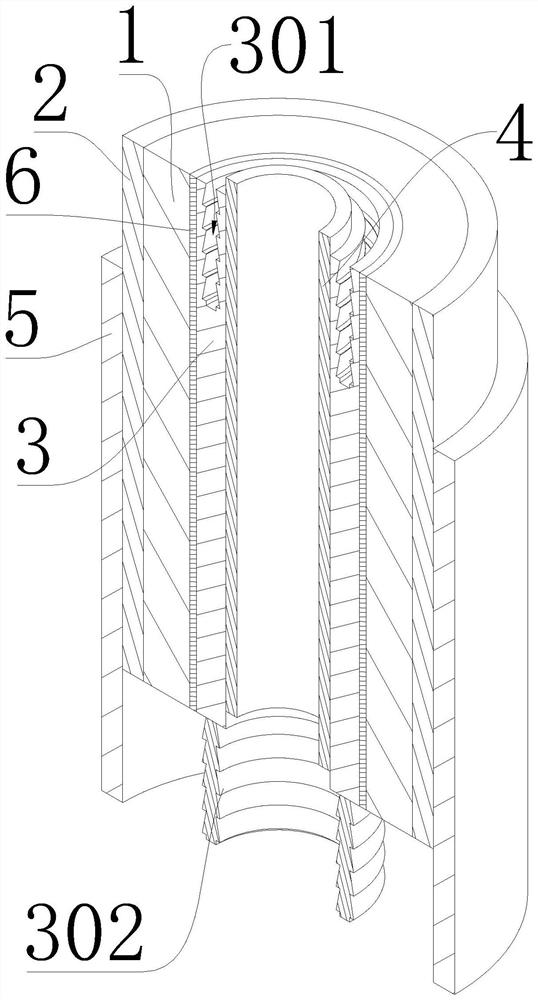

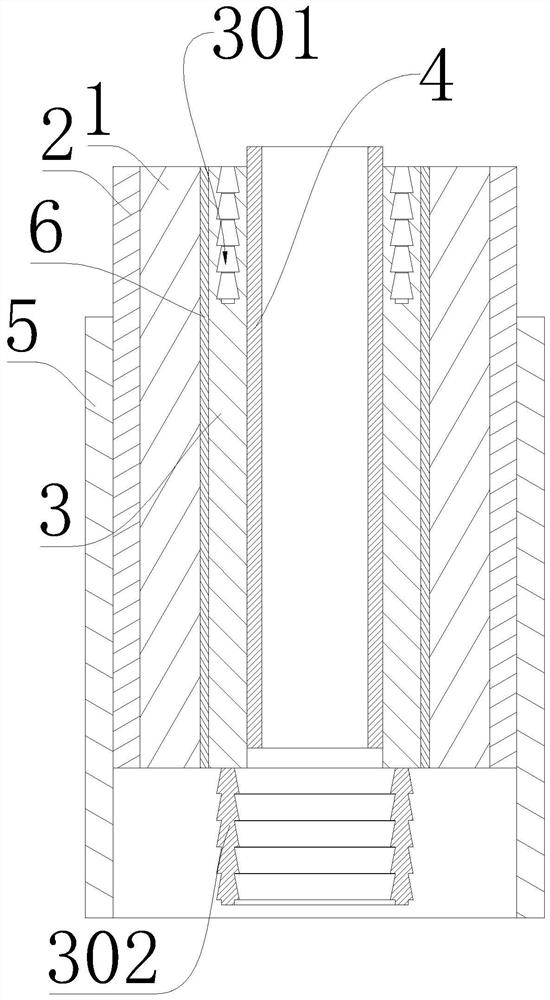

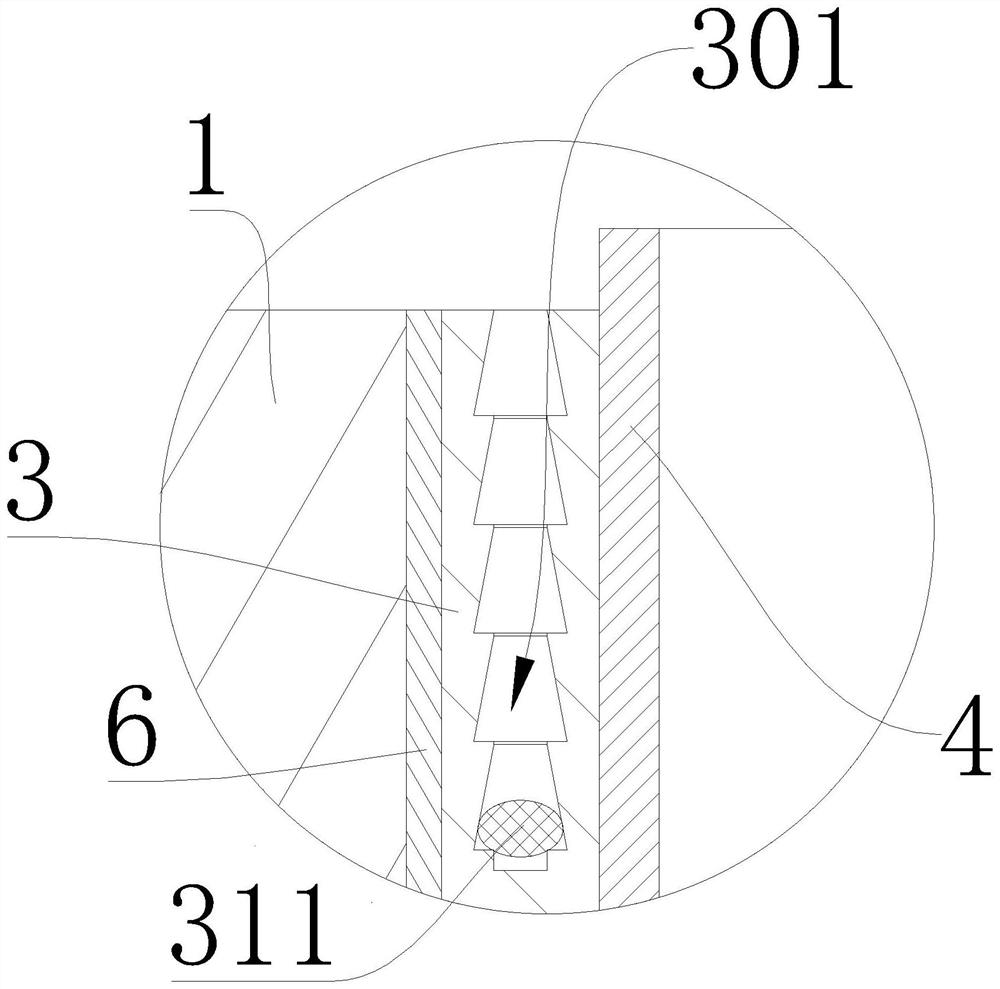

[0035] like figure 1 , 2 , 3, this embodiment provides a corrosion-resistant oil casing, including a casing body and a current sensor; the above-mentioned casing body sequentially includes an insulating protective layer 5, an anode sacrificial layer 2, a core support layer 1, The connection layer 3; the anode sacrificial layer 2, the core support layer 1 and the current sensor are electrically connected in sequence.

[0036] In this embodiment, it includes a casing body and a current sensor, wherein the current sensor can be a common commercially available component, which is easy to purchase and replace. The current sensor includes an ammeter, and the ammeter is connected to the control terminal, so that the user can know the resistance Whether there is current generated in the corrosion-resistant oil casing to detect the working state of the corrosion-resistant oil casing.

[0037] The above-mentioned casing body sequentially includes an insulating protective layer 5, an a...

Embodiment 2

[0056] This embodiment provides a method for preparing a corrosion-resistant oil casing, which includes the following steps: after heating and expanding the anode sacrificial layer 2, it is sleeved on the outer peripheral side of the core support layer 1; after the anode sacrificial layer 2 is cooled and shrinked, An insulating protective layer 5 is sheathed on the outer peripheral side of the sacrificial layer 2; a connecting layer 3 is sheathed on the inner peripheral side of the core support layer 1; a flexible buffer layer 6 is filled between the core supporting layer 1 and the connecting layer 3; the inner peripheral side of the connecting layer 3 The inner protective layer 4 is applied.

[0057] In this embodiment, the following steps are included: the anode sacrificial layer 2 is sheathed on the outer peripheral side of the core support layer 1 after being heated and expanded; after the anode sacrificial layer 2 is cooled and shrunk, an insulation protection is sheathed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com