Electric diaphragm pump

A diaphragm pump and diaphragm technology, applied in pumps, pump components, machines/engines, etc., can solve problems affecting the strength of components, and achieve the effects of reliable connection strength, saving material consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

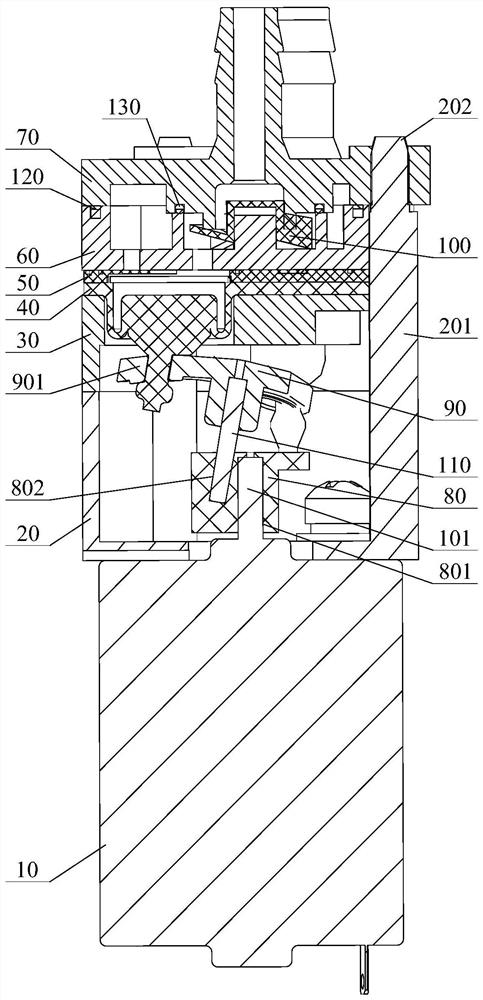

[0032] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

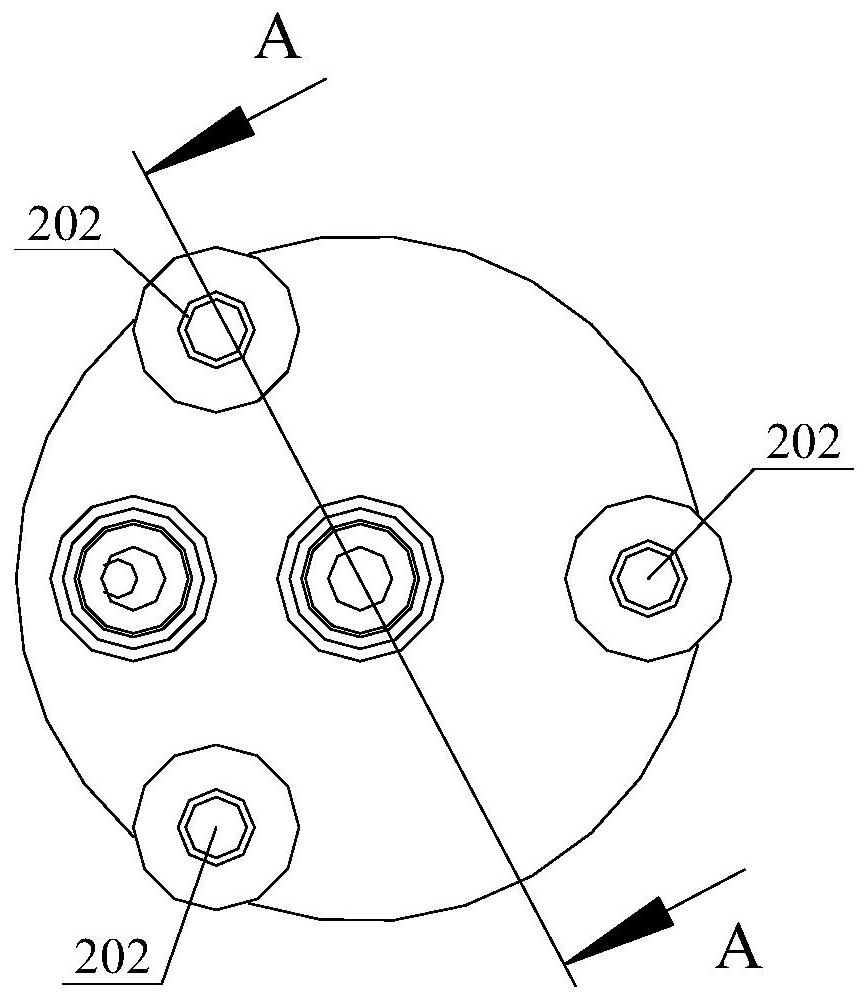

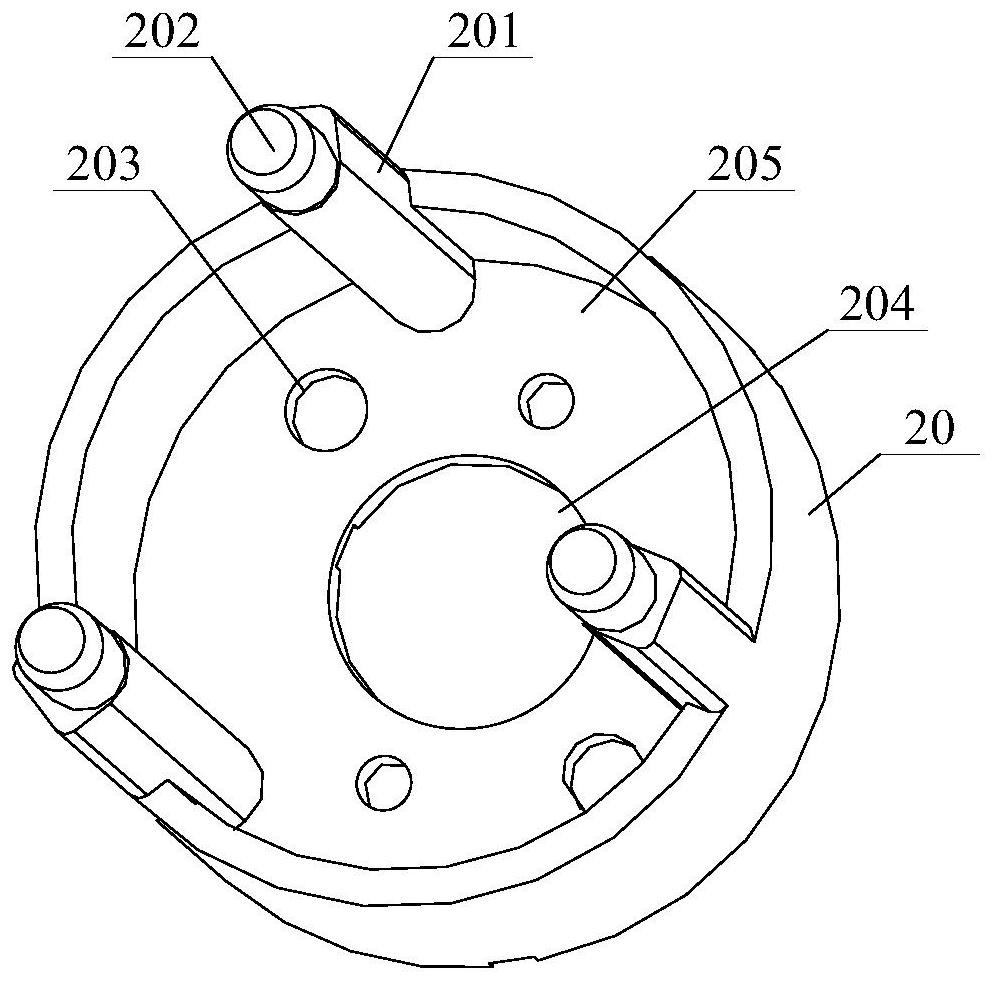

[0033] Without loss of generality, this implementation is based on figure 1 The electric diaphragm pump with three groups of piston chambers and water inlets, and one group of water outlet chambers and water outlets shown in the figure is used as a description body to describe this scheme in detail. It should be understood that the specific number of the water inlet and outlet channels does not constitute a substantial limit to the technical solution claimed in the present application.

[0034] See figure 1 and figure 2 ,in, figure 1 A schematic diagram of the overall structure of the electric diaphragm pump according to this embodiment, the figure is figure 2 The diagram formed by the A-A section of , figure 2 This is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com