Straight claw type rotor profile for dry vacuum pump and design method of straight claw type rotor profile

A technology of dry vacuum pump and rotor profile, which is applied to components of pumping devices for elastic fluids, rotary piston pumps, rotary piston/swing piston pump components, etc., and can solve the problem of affecting dry vacuum pump pumping Air performance and other issues to achieve the effect of improving volume utilization efficiency, increasing suction volume, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

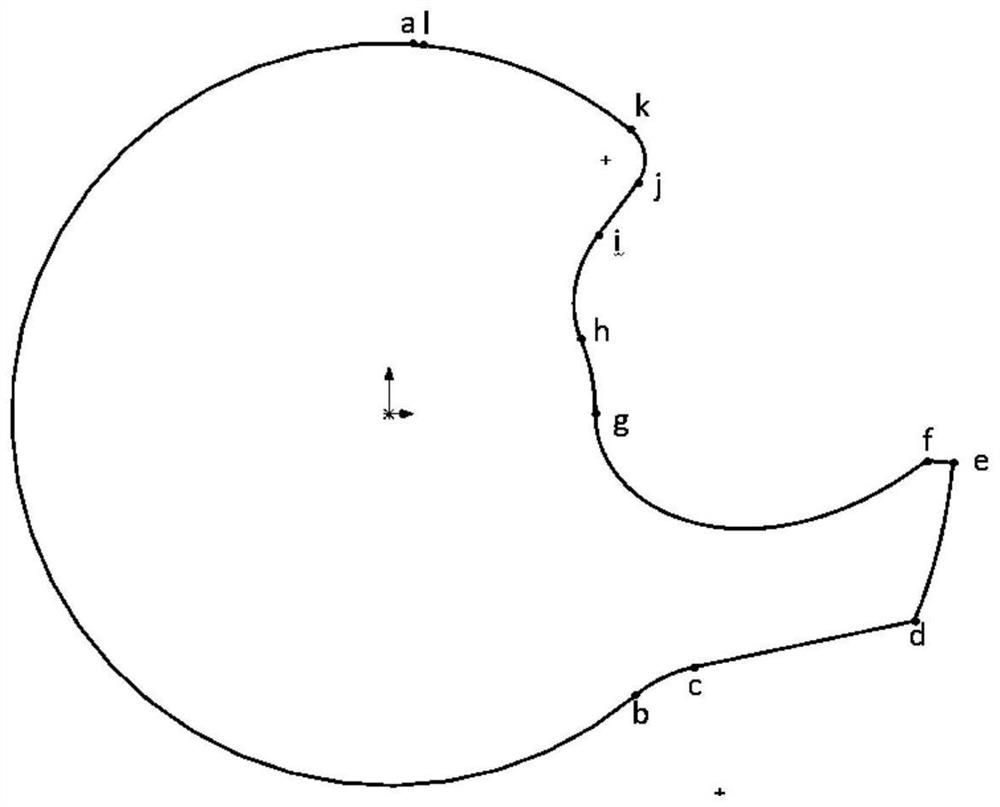

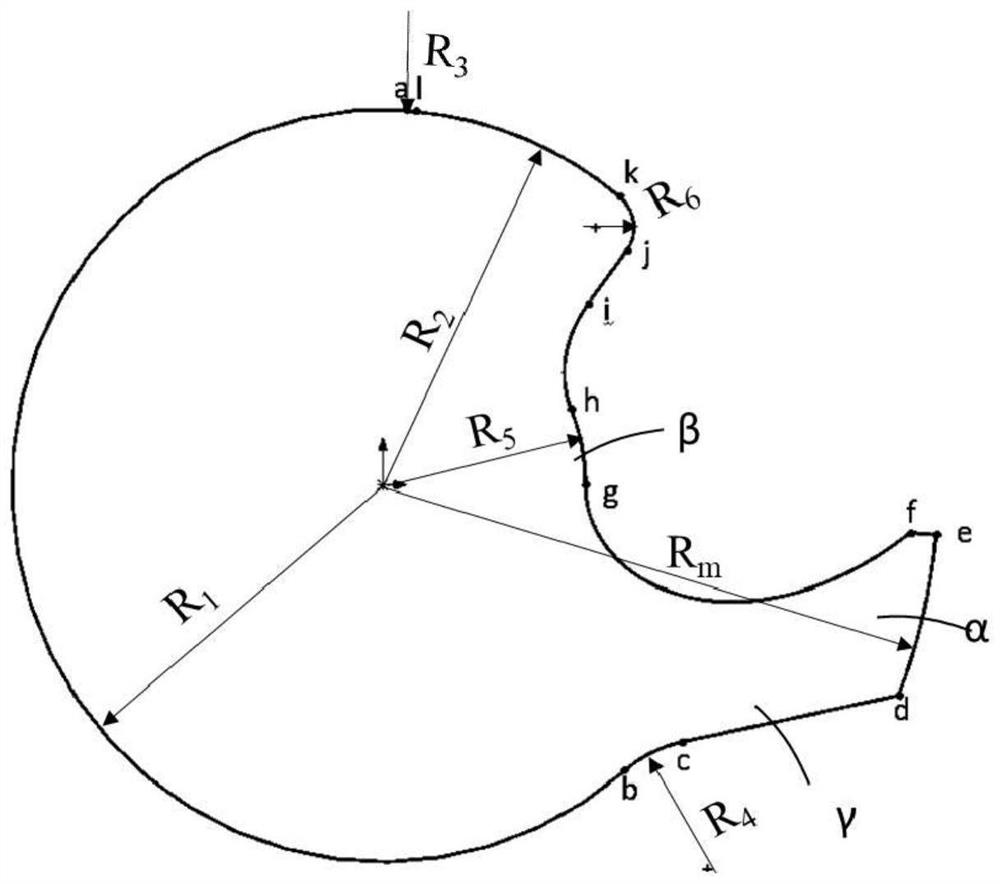

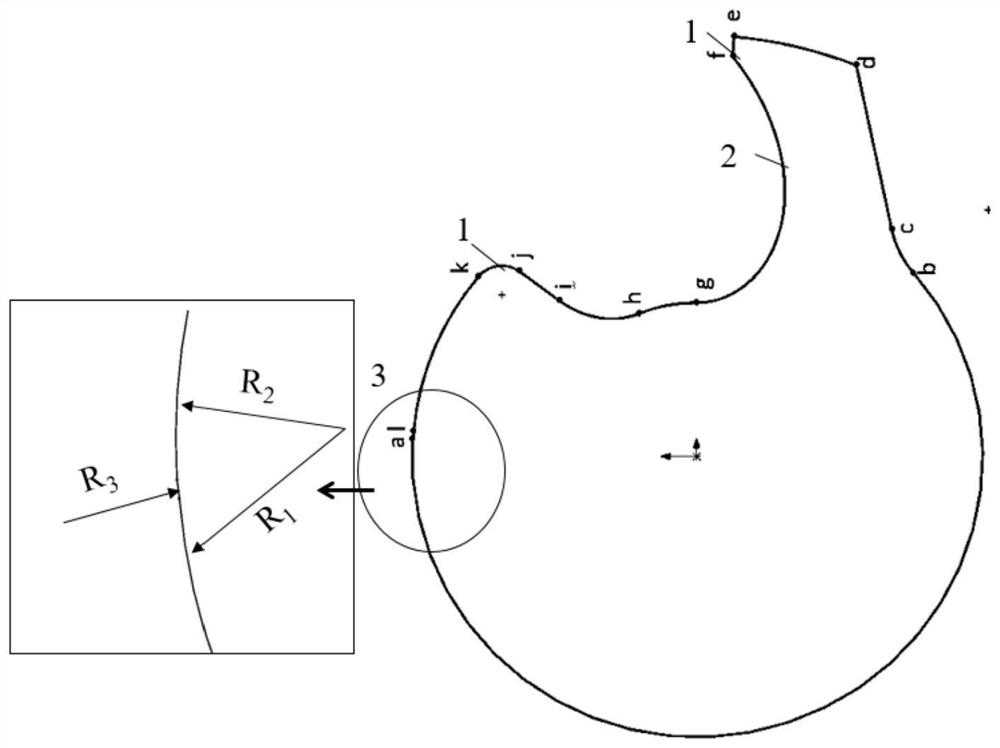

[0052] like figure 1 As shown, it is a schematic diagram of the rotor profile of the present invention. The present invention consists of three line types and twelve-segment curves, namely, 7-segment arcs, 3-segment straight lines, and 2-segment cycloids, including: counterclockwise claw tips connected end to end Straight line ef, cycloid fg at the claw arm, arc gh at the base of the claw, cycloid hi at the base of the claw, straight line ij at the base of the claw, arc jk to remove acute angles, arc kl at the pitch circle, small arc la of the pitch circle, pitch circle The arc ab, the arc bc at the claw arm, the straight line cd of the claw arm and the arc de at the top of the claw;

[0053] The rotor profile does not have any cusps in the form of acute angles, and is smoothly connected with other profiles by small arcs or straight lines at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com