Novel overflow plug valve used in high-pressure state

An overflow plug valve, high-pressure state technology, applied in the field of plug valves, can solve the problems of serious plug and plug tile service life, unfavorable plug valve opening and closing, etc., to extend service life, reduce friction, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

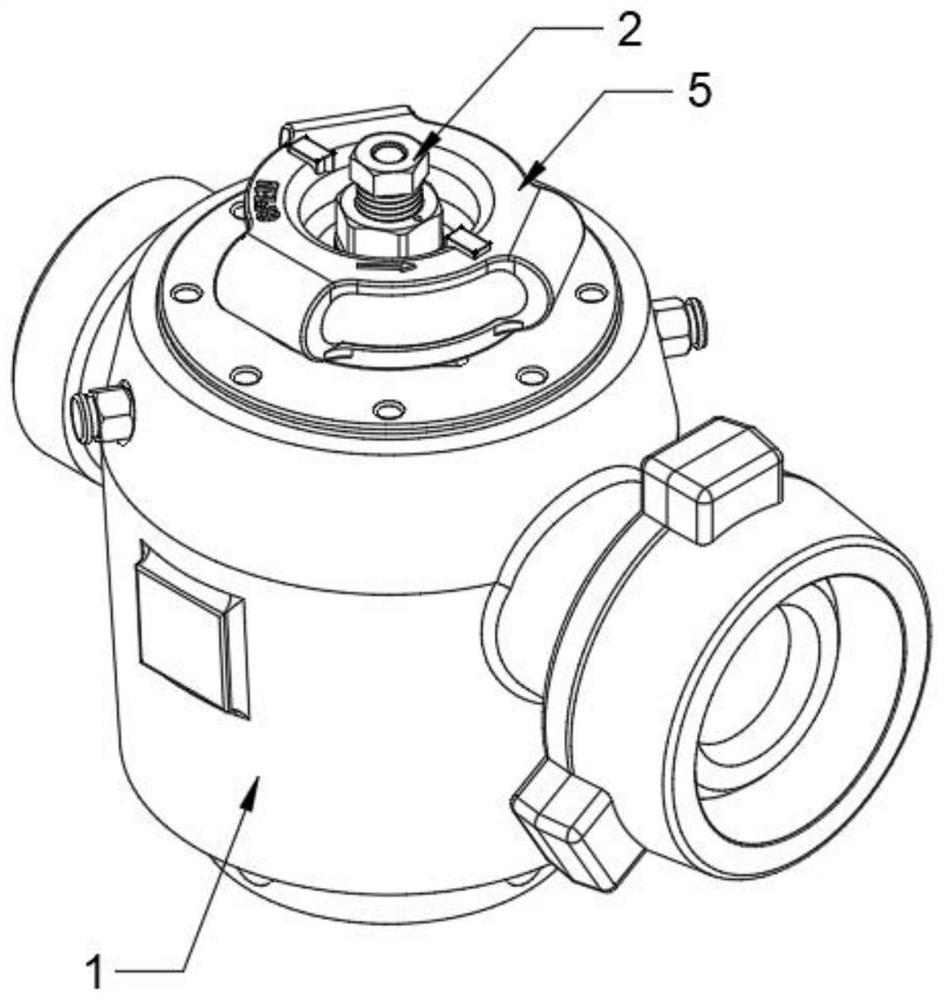

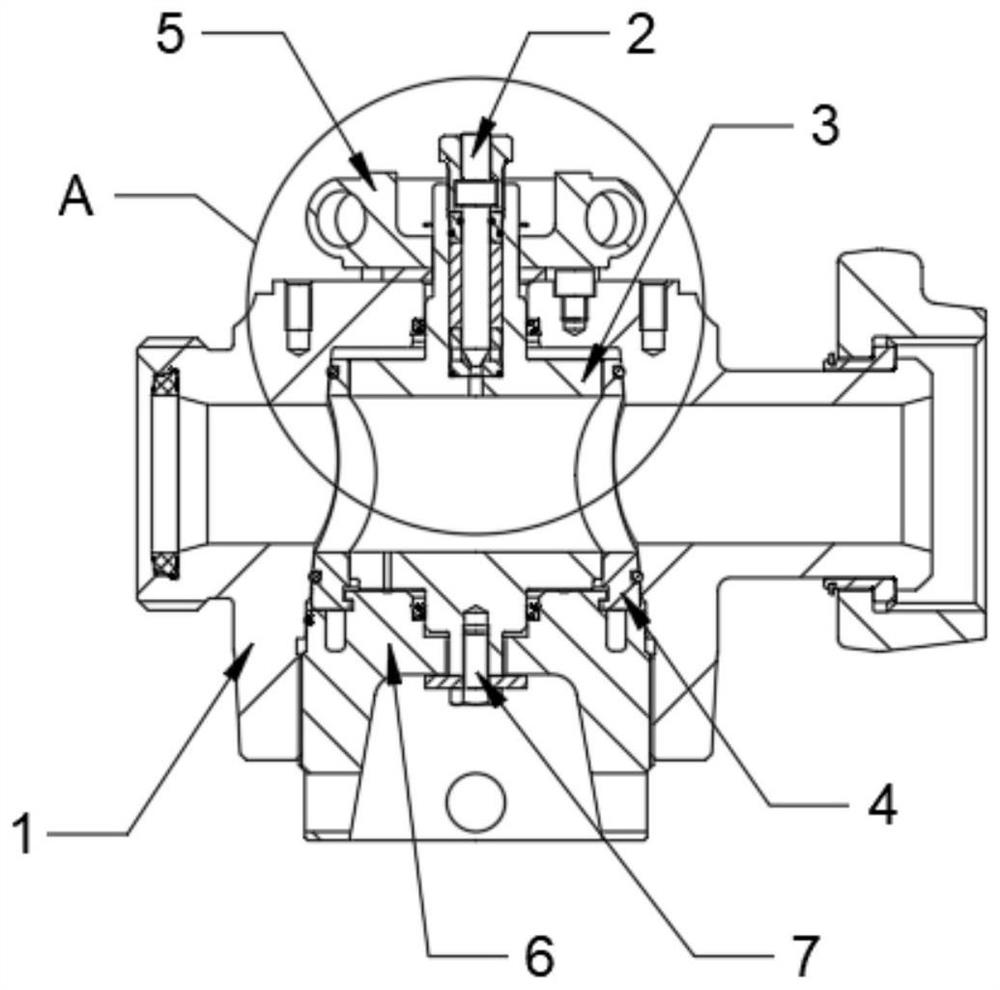

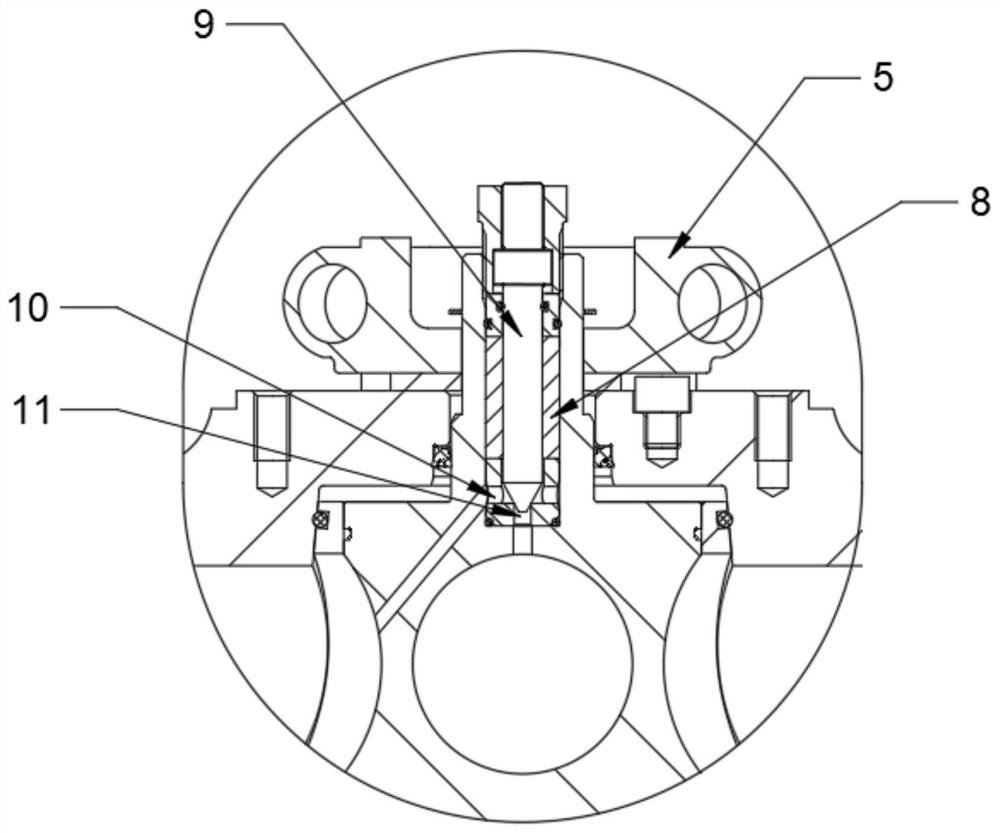

[0027] Example 1, see Figure 1-8 , the present invention provides a new type of overflow plug valve for high-pressure state, including a valve body 1, the inside of the valve body 1 is provided with a conical inner hole, and the inner hole is also provided with a cock tile 4, the cock The outer surface of the tile 4 is set as a conical surface matched with the inner hole, the side surface of the cock tile 4 is provided with a through opening, the inside of the cock tile 4 is provided with an overflow cock 3, and the top of the valve body 1 is installed with a drive. The handwheel 5 rotates the overflow cock 3, the bottom of the valve body 1 is threadedly connected with an adjusting nut 6, and the adjusting nut 6 is connected with the overflow cock 3 through the screw 7, and the overflow cock 3 includes the overflow cock main body 14, the overflow cock main body 14 has a cylindrical structure, the upper and lower end faces of the overflow cock main body 14 are respectively pro...

Embodiment 2

[0035] Example 2, see figure 2 , the present invention provides a new type of overflow plug valve for high-pressure state. Compared with Embodiment 1, the difference lies in that: the outer circle of the upper end of the adjusting nut 6 is provided with a hook groove, and the cock tile 4 is provided with a hook groove. A hook is provided on the outer circle of the bottom, and the cock tile 4 is movably connected with the adjusting nut 6 through the hook and the hook groove.

[0036] Working principle: The cock tile 4 can be moved up and down by adjusting the adjusting nut 6. Since the outer circle of the cock tile 4 is a conical surface, the inner hole of the valve body 1 is also a conical surface. When moving up along the valve body 1, the The cock tile 4 can move closer to the center, and when moving down along the valve body 1, the cock tile 4 can be separated to the outside, so as to adjust the gap between the cock tile 4 and the overflow cock 3 according to the actual use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com