Aircraft skin assembly quality detection method based on digital twinning

A quality inspection method, aircraft skin technology, applied in the direction of neural learning methods, collaborative operation devices, computer components, etc., can solve the problems of difficult extraction of deep features, low training efficiency, large number of samples, etc., to solve subtle defects The effect of missing detection and improving the quality of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings. The drawings described here are a part of the present application, and are used to further explain the present invention, but do not constitute a limitation of the present invention.

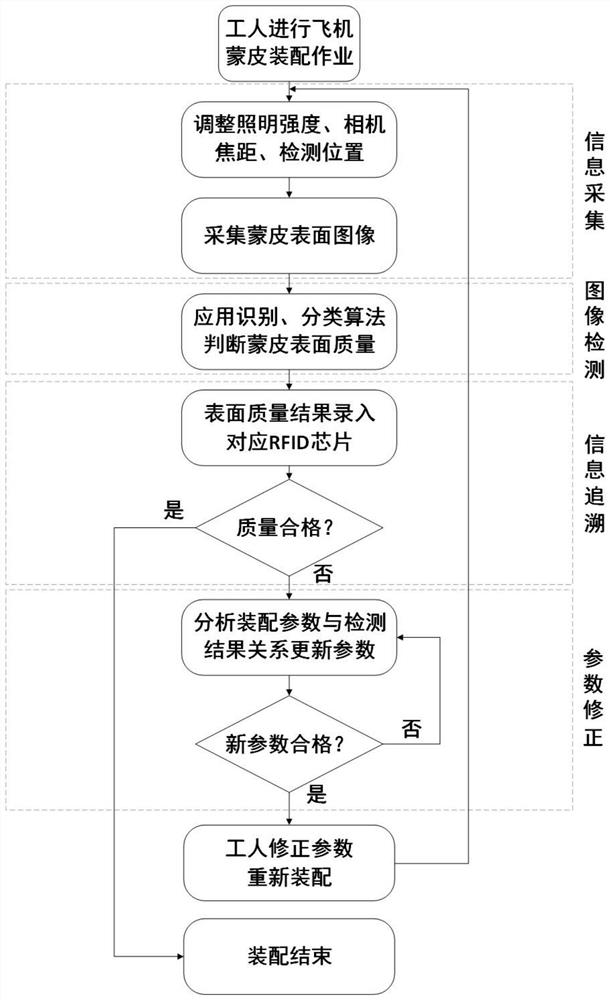

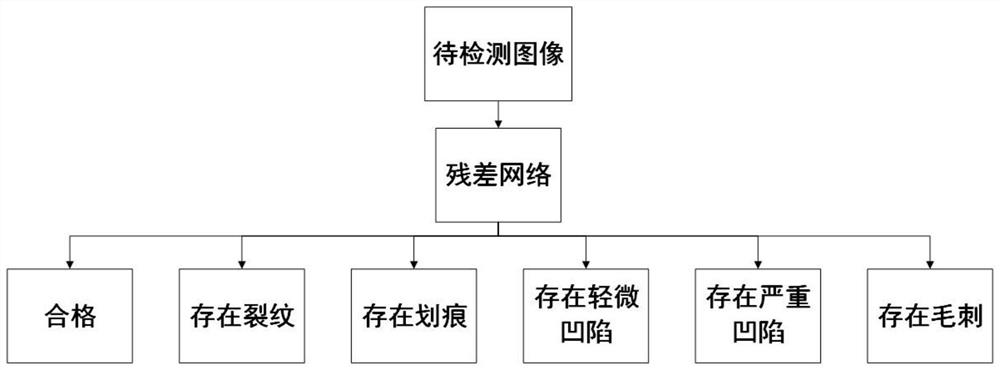

[0034] like Figure 1 to Figure 5 As shown in the figure, a digital twin-based aircraft skin assembly quality detection method mainly includes four stages, namely, the information acquisition stage, the image detection stage, the information traceability stage, and the parameter correction stage, including the following steps:

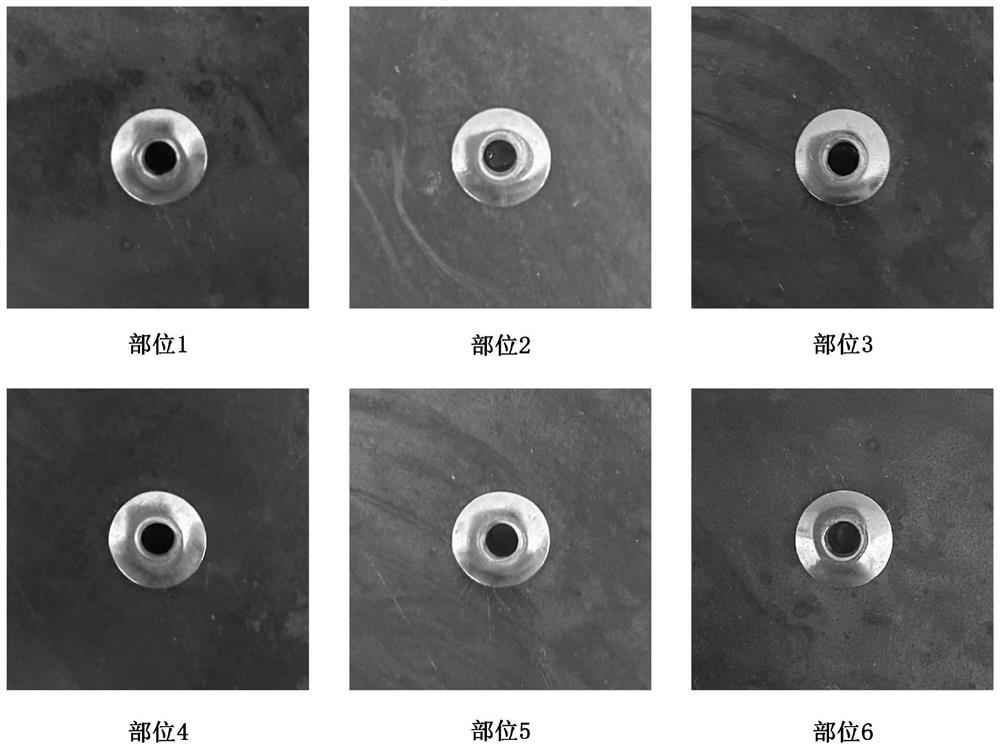

[0035] (1) In the inspection workshop, workers adjust the illumination intensity of the inspection area, adjust the camera position according to the position of the inspection area, so that the optical center of the camera is aligned with the center point of the rivet to ensure that the collected image contains complete surface features. Adjust the focal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com