Rapid disassembling device for waste lithium battery

A lithium battery, fast technology, applied in the direction of lithium batteries, battery recycling, non-aqueous electrolyte batteries, etc., can solve the problems of reduced disassembly efficiency, unfavorable for workers or equipment, etc., to avoid human contact or operation, high safety, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

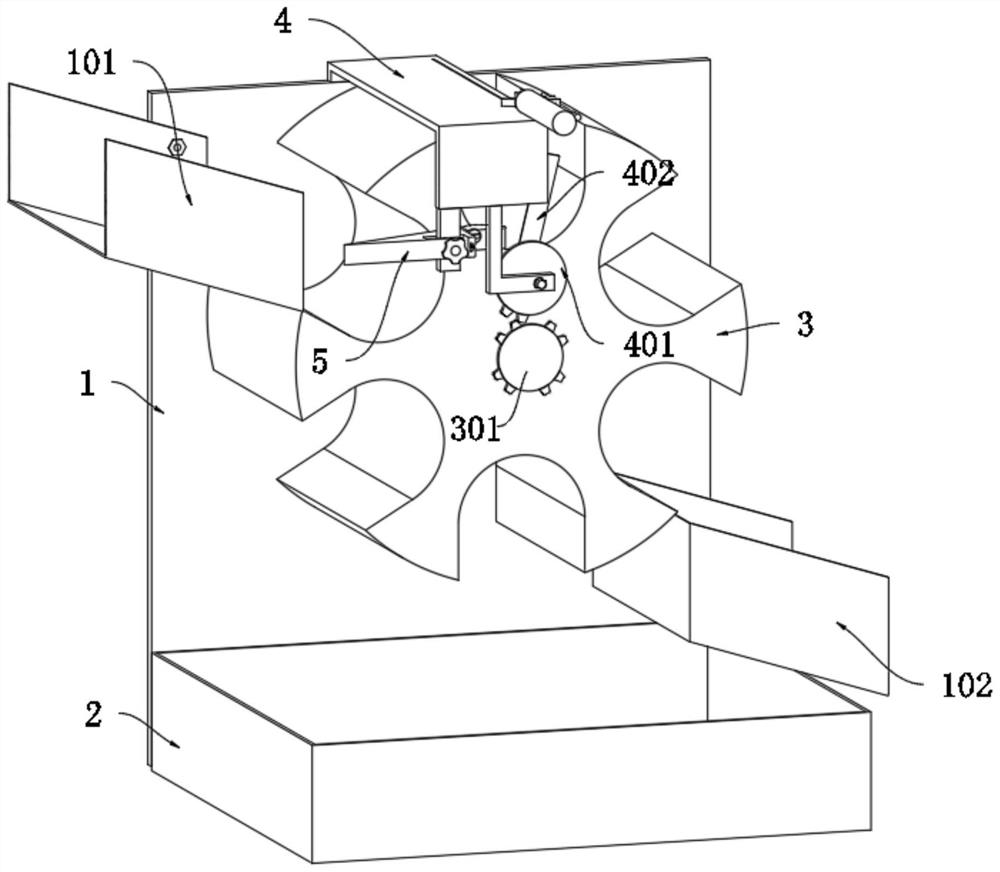

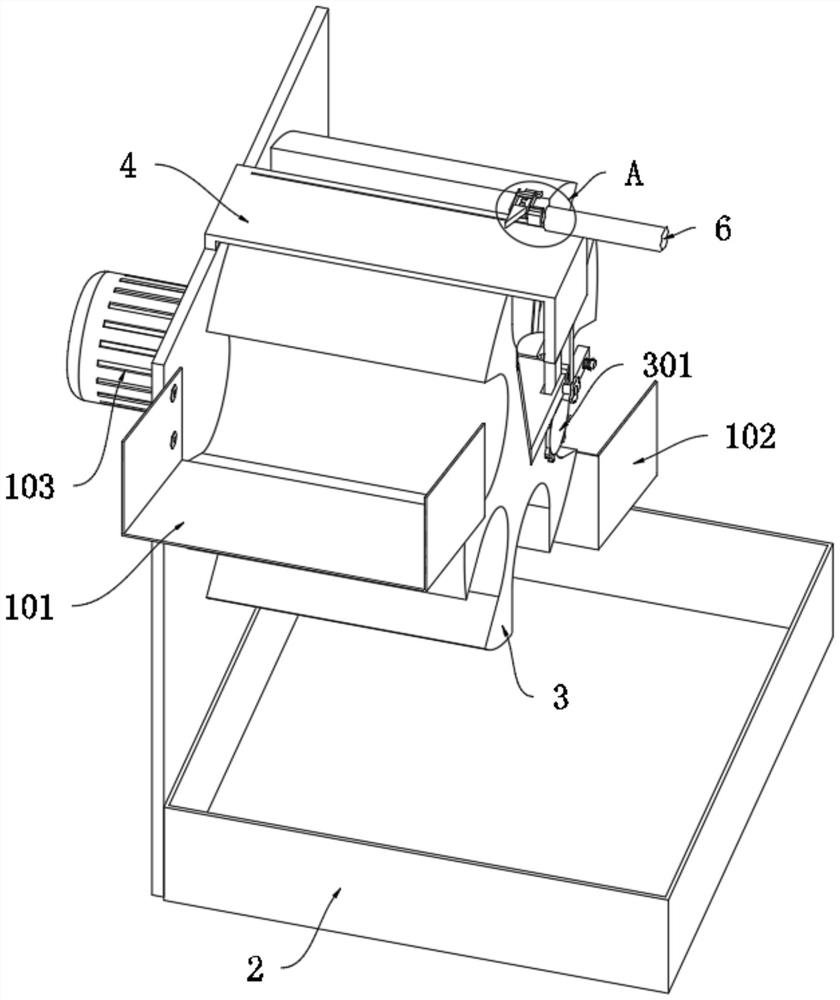

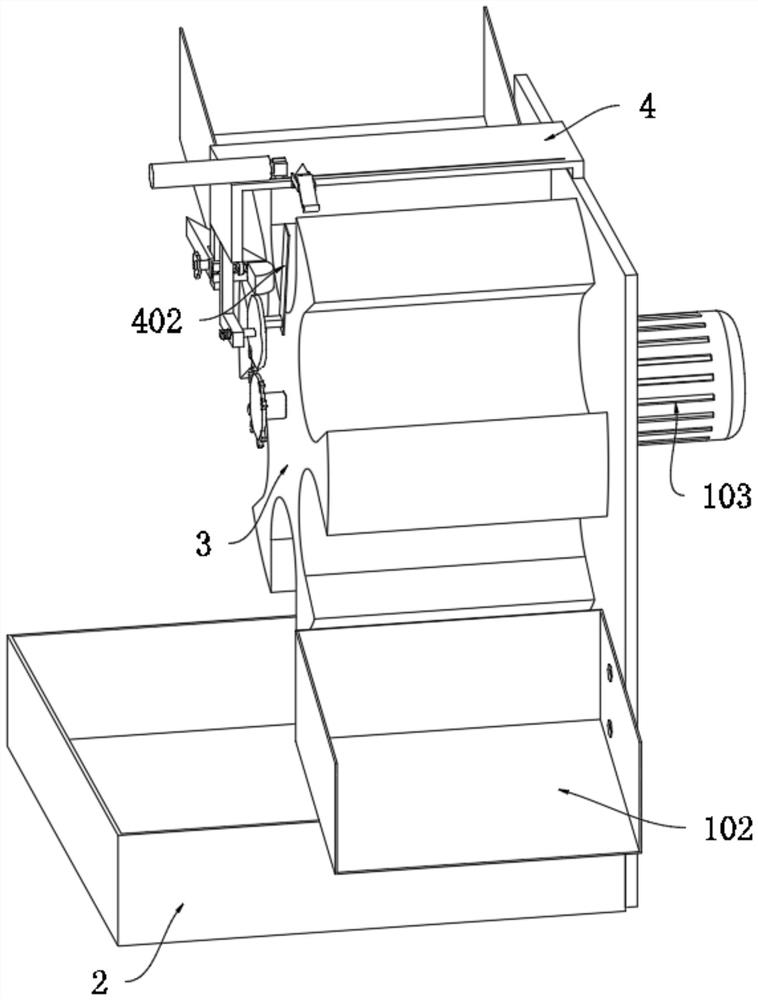

[0036] like Figure 1 to Figure 3 As shown in the figure, the quick disassembly device for waste lithium batteries in this embodiment includes a connecting plate 1, a servo motor 103 at the rear end of the connecting plate 1, a feeding place 101 above one side of the connecting plate 1, and a discharging place below one side of the connecting plate 1. 102, the output shaft of the servo motor 103 in front of the connecting plate 1 is installed with a feeding frame 3, and a first gear 301 is installed at the middle position of the front end surface of the feeding frame 3, and the connecting plate 1 above the feeding frame 3 is installed. A protective mechanism is installed on the surface, and a cutting mechanism and a wire removal mechanism are installed on the protective mechanism.

[0037] Specifically, a collection box 2 is installed on the front end surface of the connecting plate 1 below the conveying rack 3 .

[0038] At work: as Figure 1 to Figure 3 As shown in the fig...

Embodiment 2

[0040] On the basis of Example 1:

[0041] like figure 1 and Figure 4 As shown in the figure, the waste lithium battery quick disassembly device in this embodiment, further, the protection mechanism includes a material anti-warping plate 4, a reset baffle 5 and an adjustment plate 501, and the surface of the connecting plate 1 above the feeding rack 3 is installed with a material anti-warping plate Plate 4, the bottom end of the material anti-warping plate 4 is installed with a reset baffle 5, and the surface of the reset baffle 5 is installed with an adjustment disk 501.

[0042] At work: as figure 1 and Figure 4 As shown in the figure, on the basis of the rotation of the conveying rack 3, the battery inside the groove on the surface of the conveying rack 3 may extend out of the surface of the conveying rack 3 due to different falling positions. The rotation of the feeding frame 3 pushes the extended battery into the groove on the surface of the feeding frame 3, so that t...

Embodiment 3

[0044] On the basis of Examples 1 and 2:

[0045] like figure 1 and 4 As shown in the figure, the waste lithium battery quick disassembly device in this embodiment, further, the wire removing mechanism includes a second gear 401 and a scraper 402, and a second gear 401 is installed at the bottom of the material anti-warping plate 4 through a torsion spring frame, and the second gear 401 meshes with the first gear 301 for transmission, and a scraper 402 is fixedly installed on the rear end surface of the second gear 401 .

[0046] At work: as figure 1 and 4 As shown in the figure, on the basis of the rotation of the feeding rack 3 and the rotation of the first gear 301, the rotation of the first gear 301 will drive the meshed second gear 401 to rotate, because the first gear 301 is a special-shaped gear, and the smooth part is The contact between the second gear 401 and the second gear 401 will be disengaged. Since the second gear 401 is installed by the torsion spring fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com