Ink jet type special ceramic 3D printing equipment

A 3D printing and special ceramic technology, applied in the field of 3D printing, can solve the problems of nozzle clogging, simple nozzle structure, and inability to handle particles, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

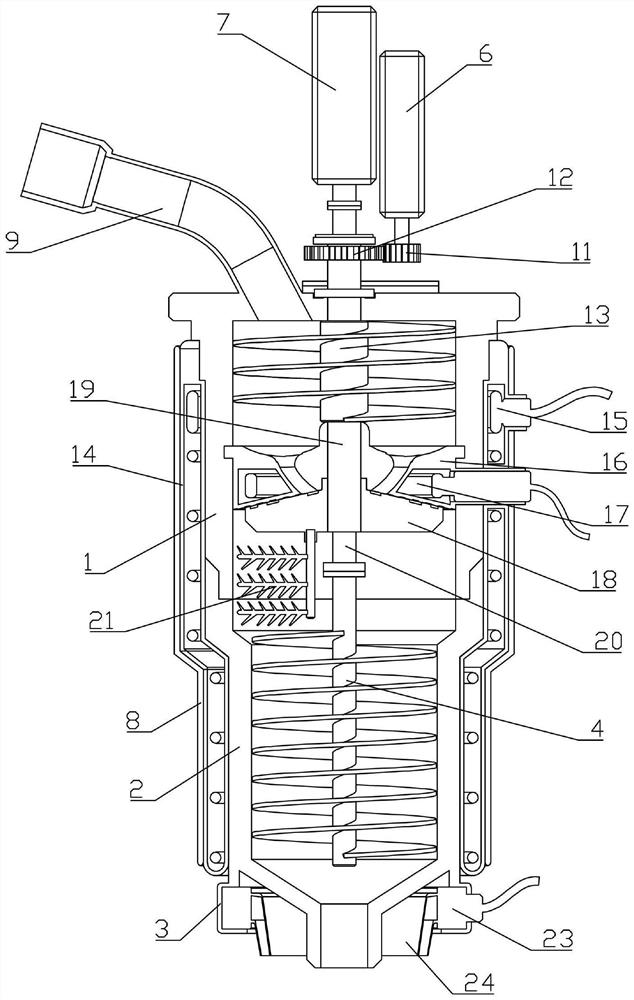

[0029] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

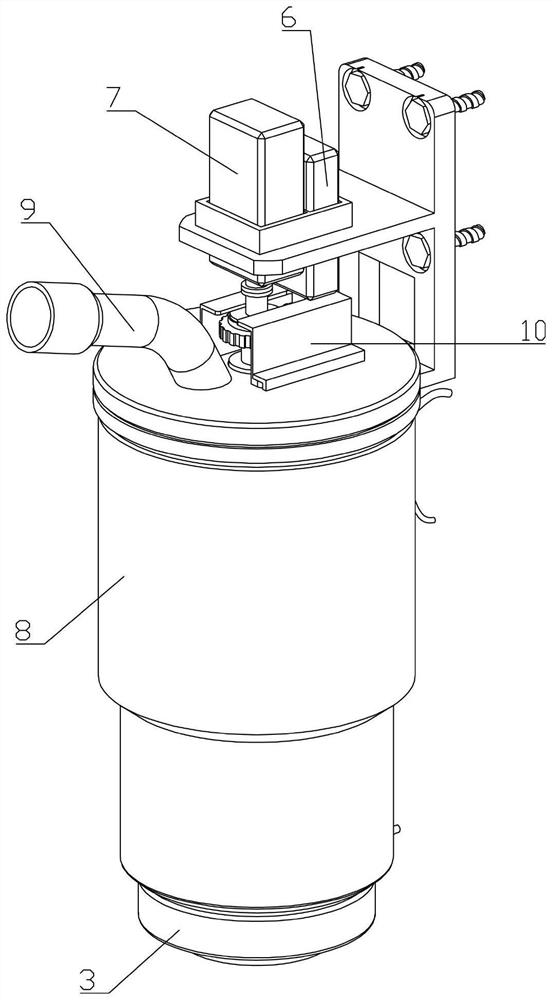

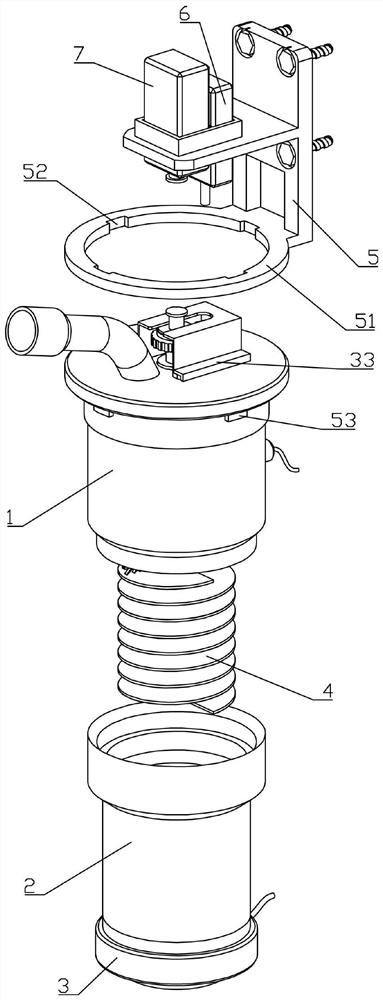

[0030] like Figure 1 to Figure 8 As shown, an inkjet-type special ceramic 3D printing equipment includes a printer main body and a nozzle. The printer main body is mainly composed of a mounting table, a printing table and a driving component that can drive the printing table to move in three directions, horizontally, vertically, and vertically. It is located above the printing table, and the nozzle is arranged on the installation table. By arranging the nozzle on the installation table, the nozzle can be placed above the printing table, and the printing table can be driven by the driving assembly in the main body of the printer, so that the printing table can be horizontally , longitudinal and vertical movement, so that the position between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com