Polishing device for sapphire glass processing

A technology of sapphire glass and grinding disc, which is applied in the direction of grinding drive device, grinding/polishing safety device, metal processing equipment, etc., which can solve the problems of inability to grind, inconvenient use and operation, and occupancy, so as to improve grinding efficiency and improve grinding efficiency. The effect of quality, prevention of scattering, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

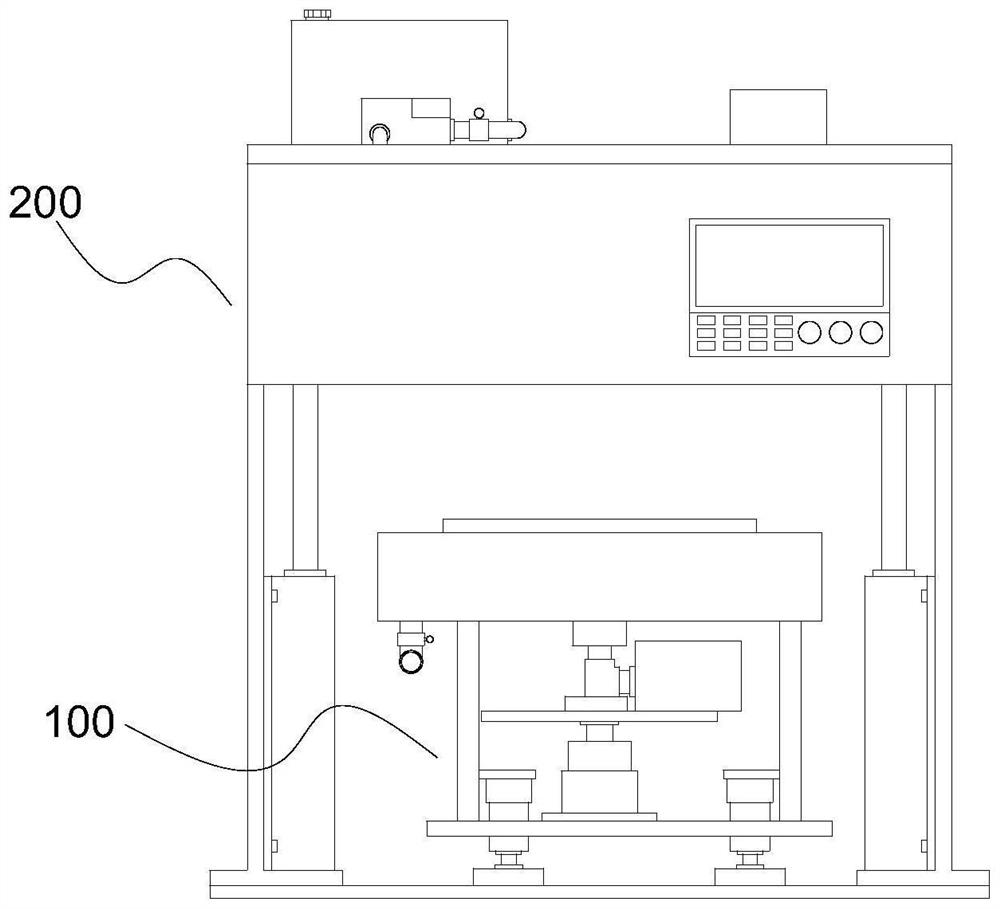

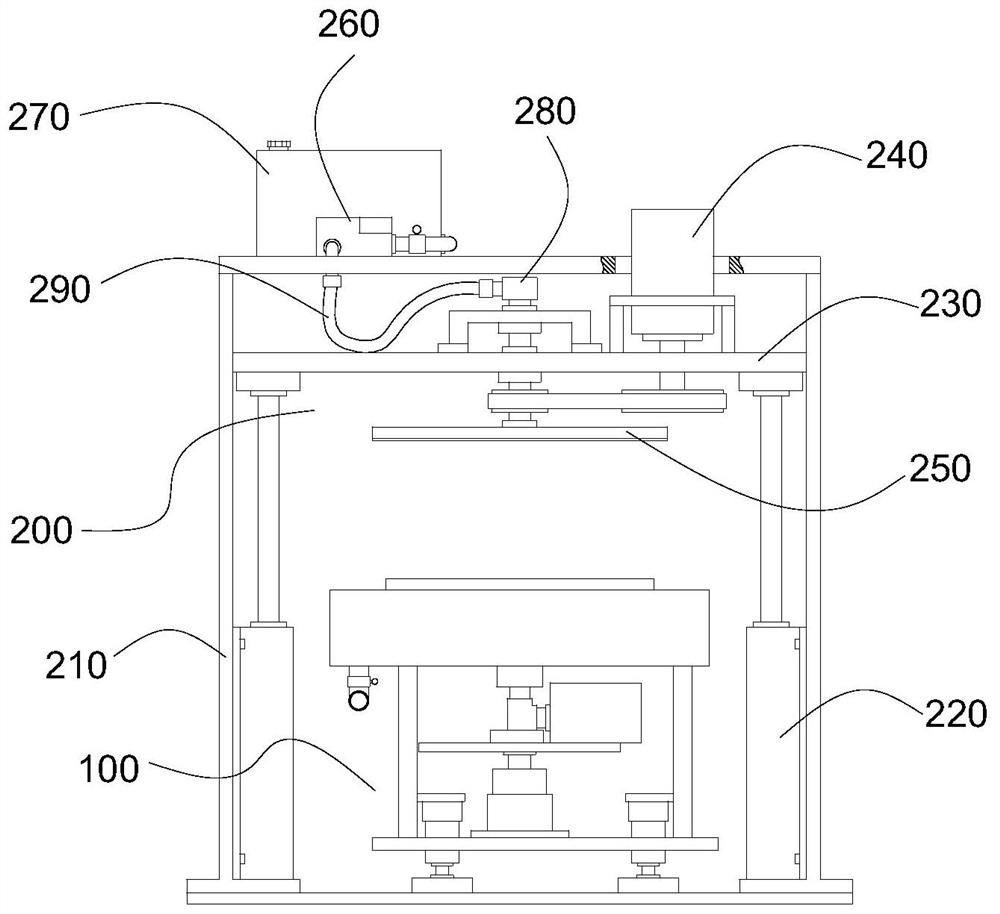

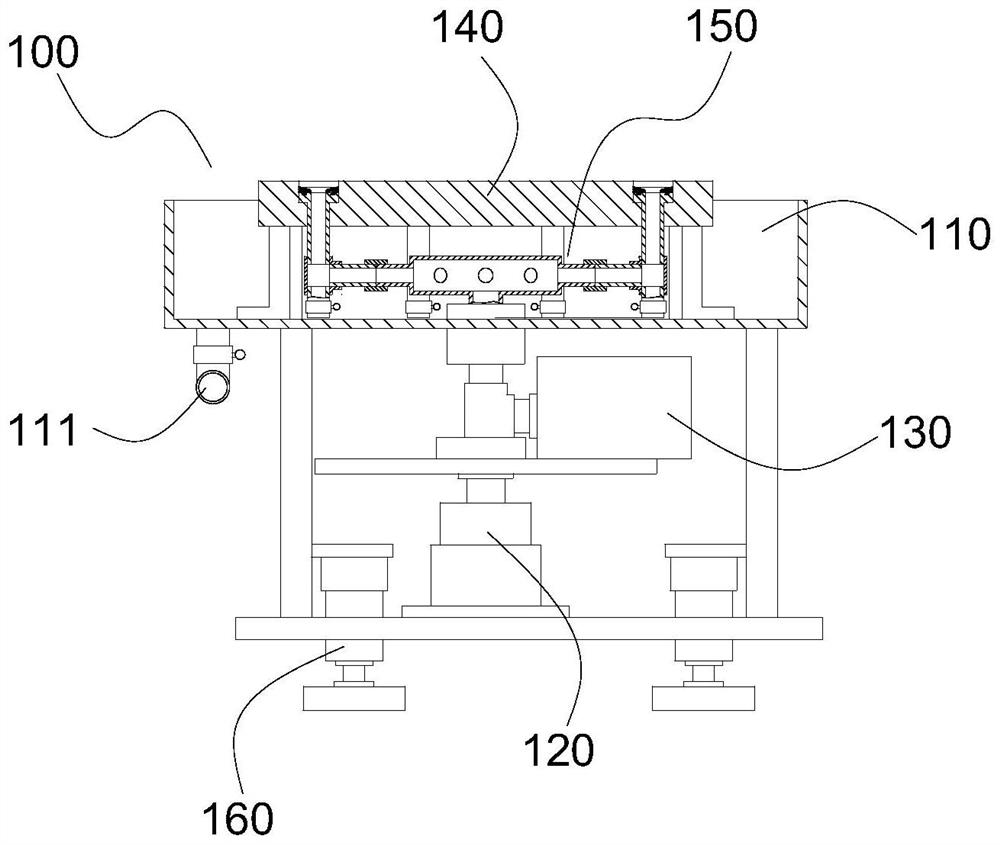

[0030] like Figure 1 to Figure 3 As shown in the figure, a specific embodiment of the present invention discloses a polishing device for sapphire glass processing, including a gripping and suction fixing structure 100 and a polishing structure 200; The grinding structure 200 can move down to the position adjacent to the gripping and suction fixing structure 100 to grind the workpiece; the gripping and suction fixing structure 100 can grip and fix the workpiece, so that the grinding surface of the workpiece is completely exposed, and the gripping and suction fixing structure 100 can To undertake grinding fluid and debris generated during the grinding process.

[0031] The above-mentioned grinding device for sapphire glass processing has a novel structure, including a gripping and suction fixing structure and a grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com