Glass ceramic, tempered glass and preparation method and application thereof

A technology of glass-ceramics and strengthened glass, which is applied in the field of glass products and can solve problems such as poor transmittance of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

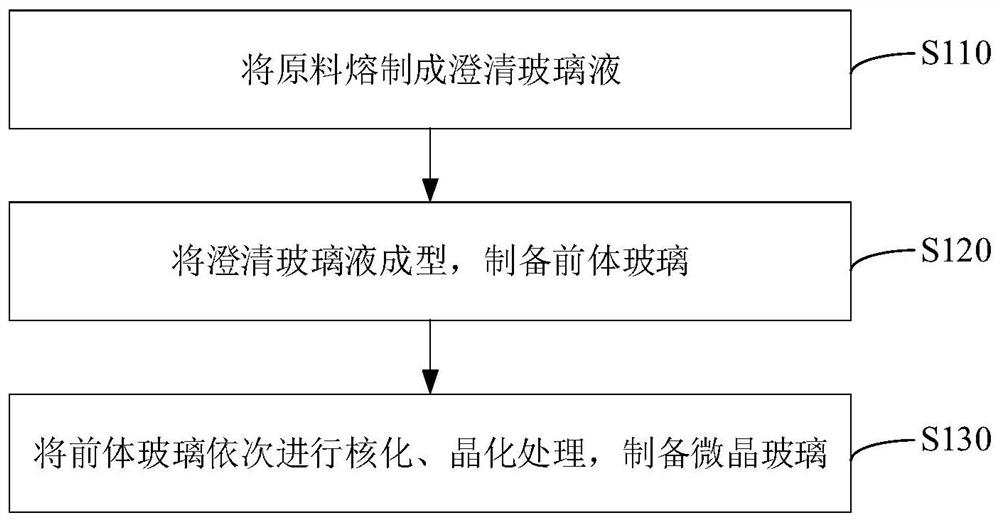

[0085] see figure 1 , another embodiment of the present invention also provides the above-mentioned preparation method of glass-ceramic, including the following steps S110-S130.

[0086] Step S110: melting the raw materials into clear glass liquid.

[0087] In some of the embodiments, in step S110, the melting temperature is 1400°C-1600°C. The melting time is 6h to 8h.

[0088] Step S120 : forming the clear glass liquid to prepare a precursor glass.

[0089] In some of the embodiments, in step S120, the forming process is selected from one of a float forming process, an overflow down-draw method, a pull-up method, a flat-draw method, and a calendering method.

[0090] Step S130: The precursor glass is sequentially subjected to nucleation and crystallization treatment to prepare glass-ceramics.

[0091] In some embodiments, in step S130, the temperature of the nucleation treatment is 500°C to 640°C; the time of the nucleation treatment is 6h to 24h.

[0092] In some embodi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap