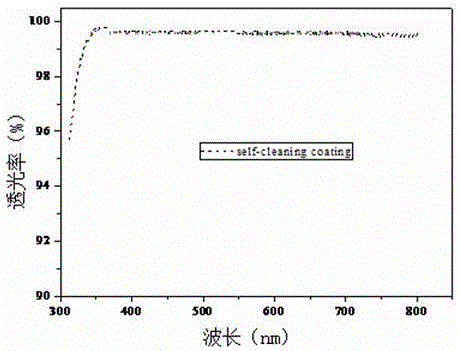

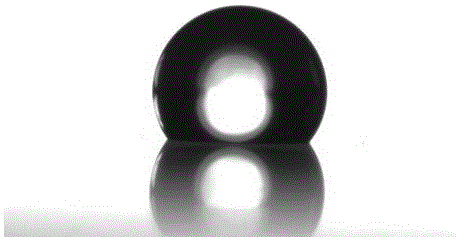

Transparent super-hydrophobic self-cleaning coating

A self-cleaning, super-hydrophobic technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve the problems of unfavorable use of bionic transparent super-hydrophobic coatings, expensive production costs of equipment, weak adhesion to substrates, etc. , to meet the performance requirements of self-cleaning applications, easy construction, and fast curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: surface band methacrylate base hydrophobic silicon dioxide nanoparticle (MSiO 2 )1 synthesis

[0022] Take 2mL tetraethyl orthosilicate, 0.12mL silane coupling agent KH570, add 35mL absolute ethanol, stir for 15min, add 3mL hexamethyldisilazane, continue stirring for 0.5h, then slowly add 3mL deionized water dropwise, room temperature Stirring and reacting for 24 hours, an ethanol dispersion liquid of silicon dioxide nanoparticles is formed, and the particle diameter of the nanoparticles is 40-80nm.

Embodiment 2

[0023] Embodiment 2: the surface band epoxy-based hydrophobic silica nanoparticles (ESiO 2 )1 synthesis

[0024] Take 2mL tetraethyl orthosilicate, 0.12mL silane coupling agent KH560, add 35mL absolute ethanol, stir for 15min, then add 3mL hexamethyldisilazane, continue stirring for 0.5h, then slowly add 3mL deionized water, room temperature Stirring and reacting for 24 hours, an ethanol dispersion liquid of silicon dioxide nanoparticles is formed, and the particle diameter of the nanoparticles is 30-70nm.

Embodiment 3

[0025] Embodiment 3: surface band methacrylate base hydrophobic silicon dioxide nanoparticle (MSiO 2 ) Synthesis of 2

[0026] Take 2mL tetraethyl orthosilicate, 0.12mL silane coupling agent KH570, add 35mL absolute ethanol, stir for 15min, add 3mL divinyltetramethyldisilazane, continue stirring for 0.5h, then slowly add 3mL deionized water, stirred and reacted at room temperature for 24 hours to form an ethanol dispersion of silicon dioxide nanoparticles, and the particle size of the nanoparticles is 20-80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com