Low-temperature rolling and heat treatment process of near-alpha type high-temperature titanium alloy

A high-temperature titanium alloy and low-temperature rolling technology, which is applied to the preparation of high-temperature titanium alloy sheets with micro-nano layered structure and the low-temperature rolling and heat treatment technology fields, can solve the problem of insufficient strength, poor creep resistance, and mesh basket structure creep. Insufficient strength and plasticity to achieve the effect of improving comprehensive mechanical properties and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

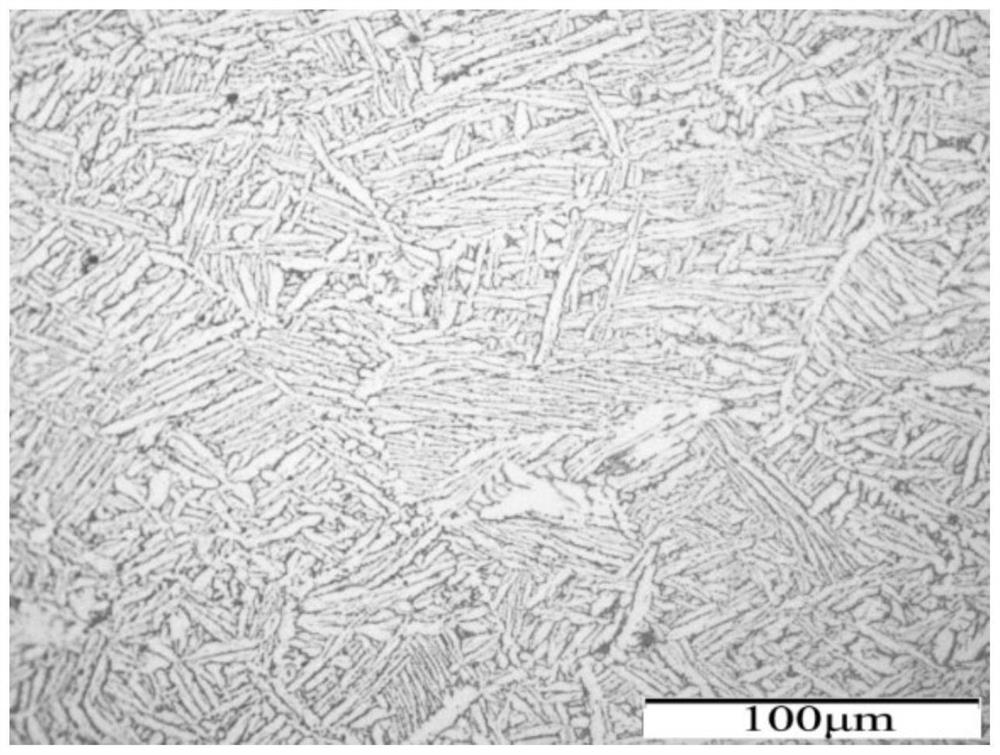

Embodiment 1

[0032] In the near-α type high-temperature titanium alloy of this embodiment, the composition elements of the high-temperature titanium alloy are: Al: 6.1%, Sn: 3.0%, Zr: 5.1%, Mo: 0.5%, Nb: 1.1%, Ta: 0.9 %, Si: 0.4%, Er: 0.2%, and the remainder is Ti. A high-temperature titanium alloy ingot is obtained by a conventional casting method, and then the β / (α+β) phase transition point of the alloy is obtained by DSC (differential scanning calorimeter) test to be 1001°C. The first step is to open and forge through the β single-phase zone at 1150°C, and then finish forging at 980°C to obtain a bar with Widmanscher structure. The second step is to carry out double-stage spheroidization at 980°C / 1h-880°C / 2h to obtain the following figure 2 Isometric organization shown. In the third step, heat treatment at 990°C / 1h to obtain a dual-state structure with a primary α phase content of 13%, such as image 3 shown. In the fourth step, the two-state structure obtained in the previous step...

Embodiment 2

[0033] Example 2 (comparative example)

[0034] The near-α-type high-temperature titanium alloy of this example has the same alloy composition as that of Example 1. A high-temperature titanium alloy ingot was obtained by a conventional casting method, and then the β / (α+β) phase transition point of the alloy was obtained by DSC (differential scanning calorimeter) test to be 1001°C. In the first step, the 1150°C beta single-phase zone will be billet forged, followed by precision forging at 980°C to obtain a bar with Widmanners structure. The second step is to carry out double-stage spheroidization at 980°C / 1h-880°C / 2h to obtain the following figure 2 Isometric organization shown. In the third step, heat treatment at 990°C / 1h to obtain a dual-state structure with a primary α phase content of 13%, such as image 3 shown. In the fourth step, the two-state structure obtained in the previous step was kept at 880 ° C for 20 minutes, and the first hot rolling with a deformation am...

Embodiment 3

[0036]The near-α-type high-temperature titanium alloy of this example has the same alloy composition as that of Example 1. A high-temperature titanium alloy ingot is obtained by a conventional casting method, and then the β / (α+β) phase transition point of the alloy is obtained by DSC (differential scanning calorimeter) test to be 1001°C. The first step is to open and forge through the β single-phase zone at 1150 °C, and then finish forging at 980 °C to obtain a bar with Widmanners structure. The second step is to carry out double-stage spheroidization at 980°C / 1h-880°C / 2h to obtain the following figure 2 Isometric organization shown. In the third step, heat treatment at 990°C / 1h to obtain a dual-state structure with a primary α phase content of 13%, such as image 3 shown. In the fourth step, the dual-state structure obtained in the previous step was kept at 880 ° C for 20 minutes, and the first hot rolling was performed with a deformation amount of 10%; Hot rolling, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com