Display panel and preparation method thereof

A display panel and panel technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

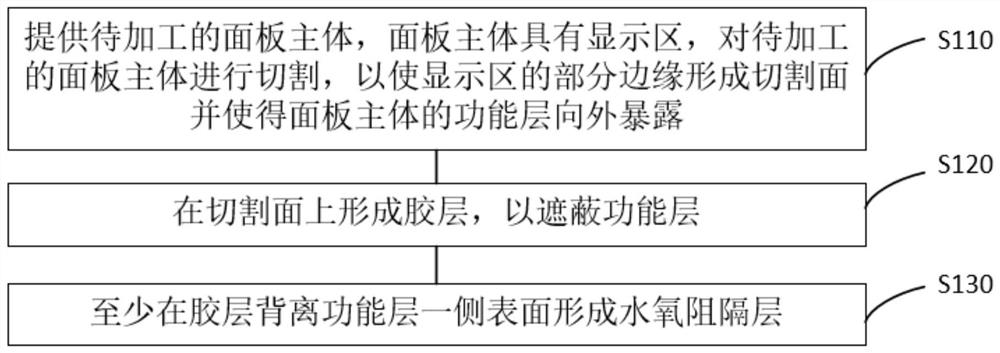

[0048] The present invention also provides a method for preparing a display panel. The display panel has a display area AA, which includes the following steps:

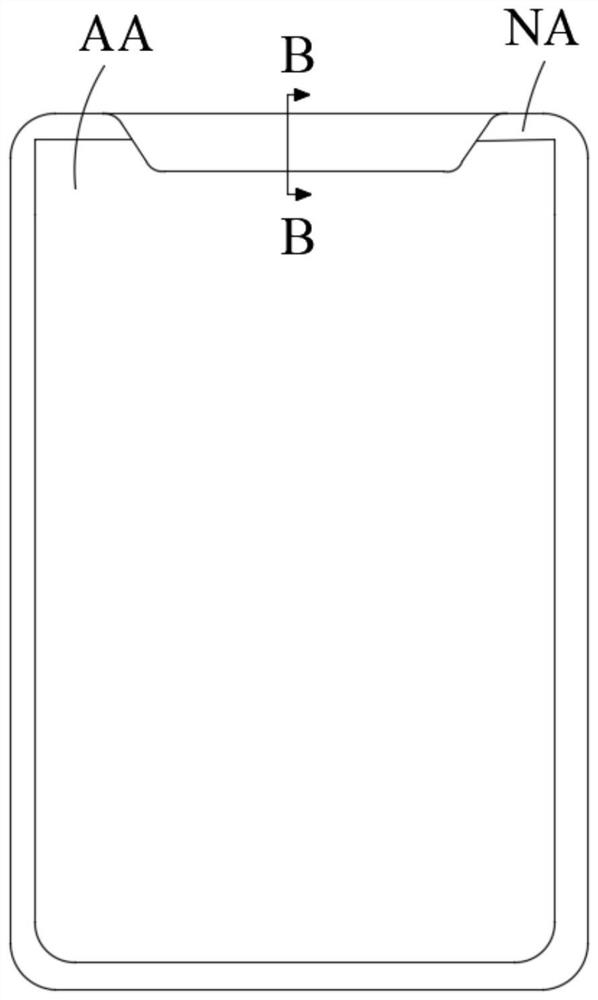

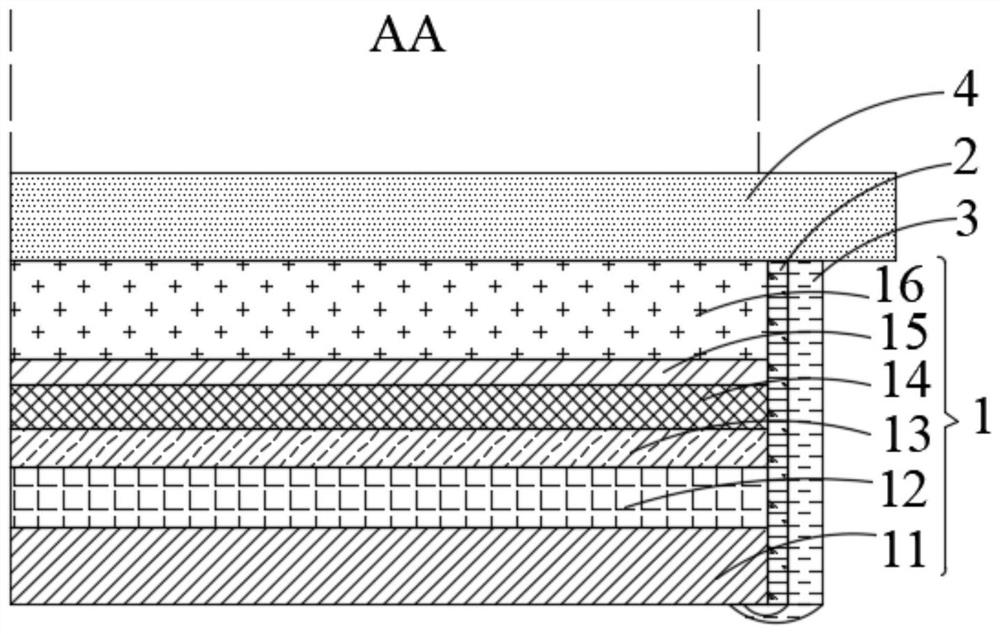

[0049] S110: Provide a panel body 1 to be processed, the panel body 1 has a display area AA, and cut the panel body 1 to be processed so that a part of the edge of the display area AA forms a cut surface and exposes the functional layer of the panel body 1 to the outside, like Figure 4 to Figure 7 shown, where, Figure 4 and Figure 5 It is a schematic structural diagram and a film layer structure diagram of the panel main body 1 before cutting, Image 6 and Figure 7 It is a schematic structural diagram and a film layer structure diagram of the panel main body 1 after cutting. By comparison, it can be seen that the encapsulation layer 14 of the panel main body 1 in the non-display area NA and the film layer in the display area AA are both cut and removed after cutting.

[0050] S120: Form an adhesive layer 2 on ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap