High-vibration-resistance quick-locking base

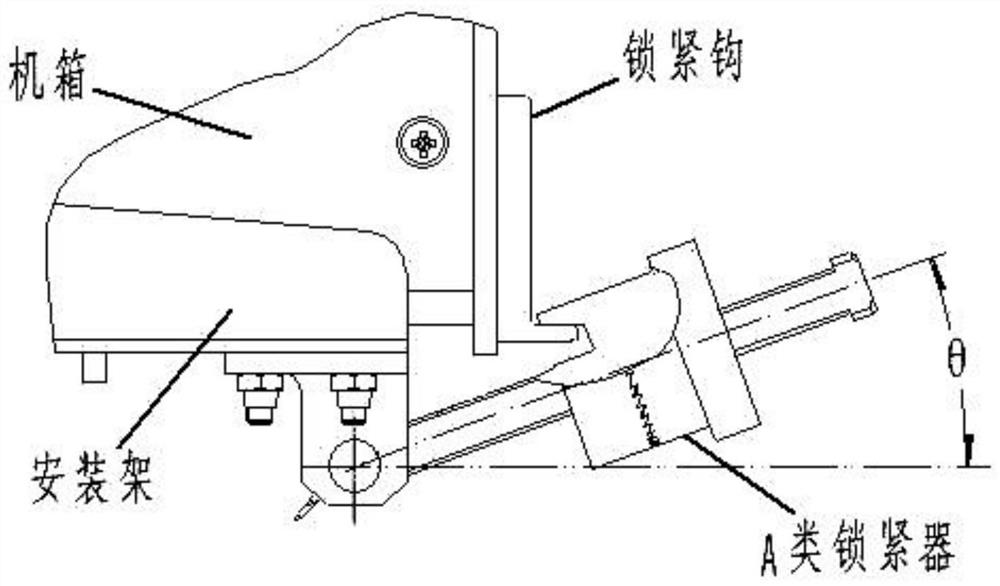

A fast-locking, high-resistance technology, which is applied in the direction of electrical equipment shells/cabinets/drawers, casings/cabinets/drawer parts, electrical components, etc., can solve problems that cannot meet high-level and long-term vibration requirements , to achieve the effect of meeting high-level vibration requirements, reliable locking, and enhancing anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the content of the present invention, the present invention will be further described below with reference to specific embodiments and accompanying drawings. The following examples are implemented based on the technology of the present invention, and provide detailed implementation modes and operation steps, but the protection scope of the present invention is not limited to the following examples.

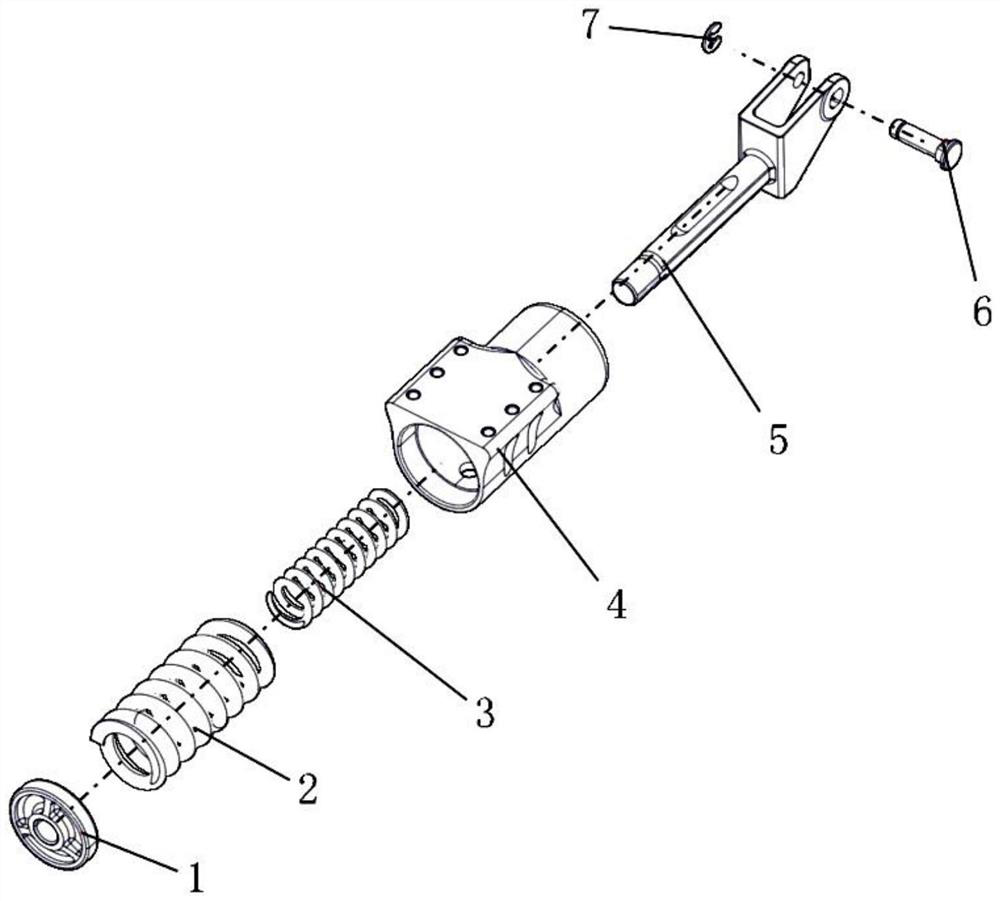

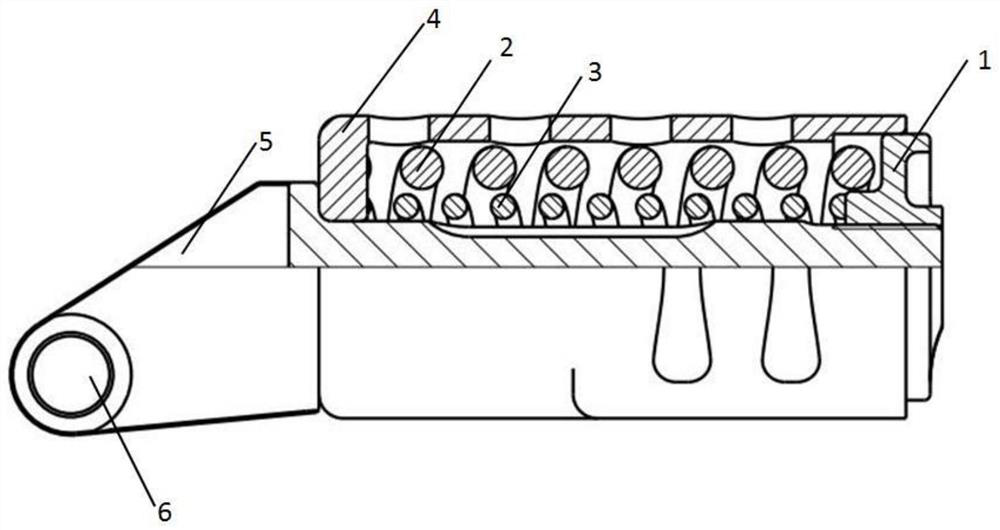

[0028] like figure 2 As shown in the figure, a high anti-vibration quick-lock base provided by the present invention specifically includes: a tail retaining ring 1, an outer ring spring 2, an inner ring spring 3, a locking base 4, a fork 5, a pin shaft 6, an opening retaining ring 7 . Among them, the outer ring spring 2 is sheathed outside the inner ring spring 3 to form an elastic mechanism and is installed in the locking base 4. One end of the locking base 4 is opened for assembling the tail retaining ring 1. The inner wall of the opening i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap