Waste gas treatment device and method for recovering epoxy chlorohydrocarbon

A waste gas treatment device, epoxy chlorocarbon technology, applied in the direction of separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of low recovery rate of epoxy chlorocarbons, excessive content of epoxy chlorocarbons, etc., to achieve improved adsorption Efficiency, reduction of epoxy chlorocarbon content, and improvement of liquid output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below.

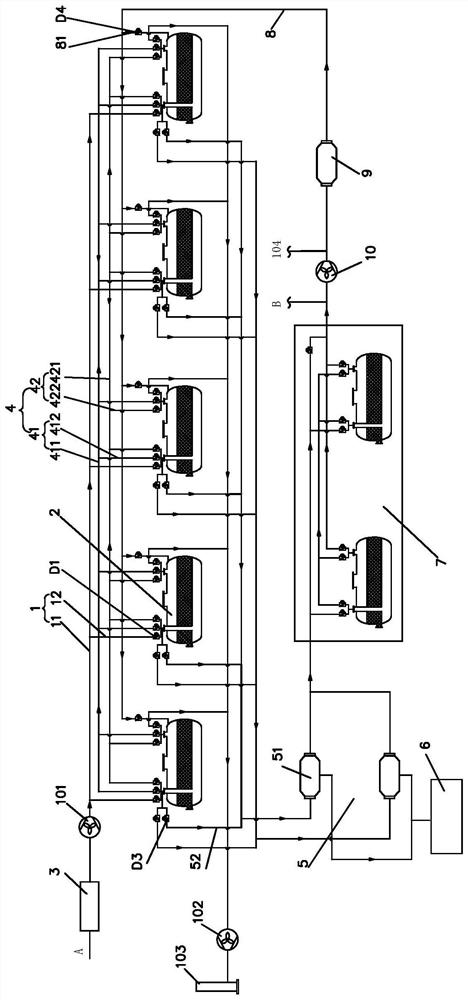

[0062] The content of epichlorohydrin in the high-concentration epichlorohydrin waste gas of the treatment object of the present invention is about 10-30 g / m3, the water content is about 15 g / m3, and the content of water and the content of epichlorohydrin are basically equal. Due to the characteristics of the decomposition of epichlorohydrin in contact with water, in order to improve the recovery efficiency of epichlorohydrin, it is very important to remove water from the waste gas; During the adsorption process, it can be completely adsorbed, so that the clean gas discharged into the atmosphere can meet the relevant emission standards. Therefore, the device of the present invention should not only meet the gas emission standard, but also ensure a high recovery rate of epichlorohydrin, which is a difficulty in the design of the present invention.

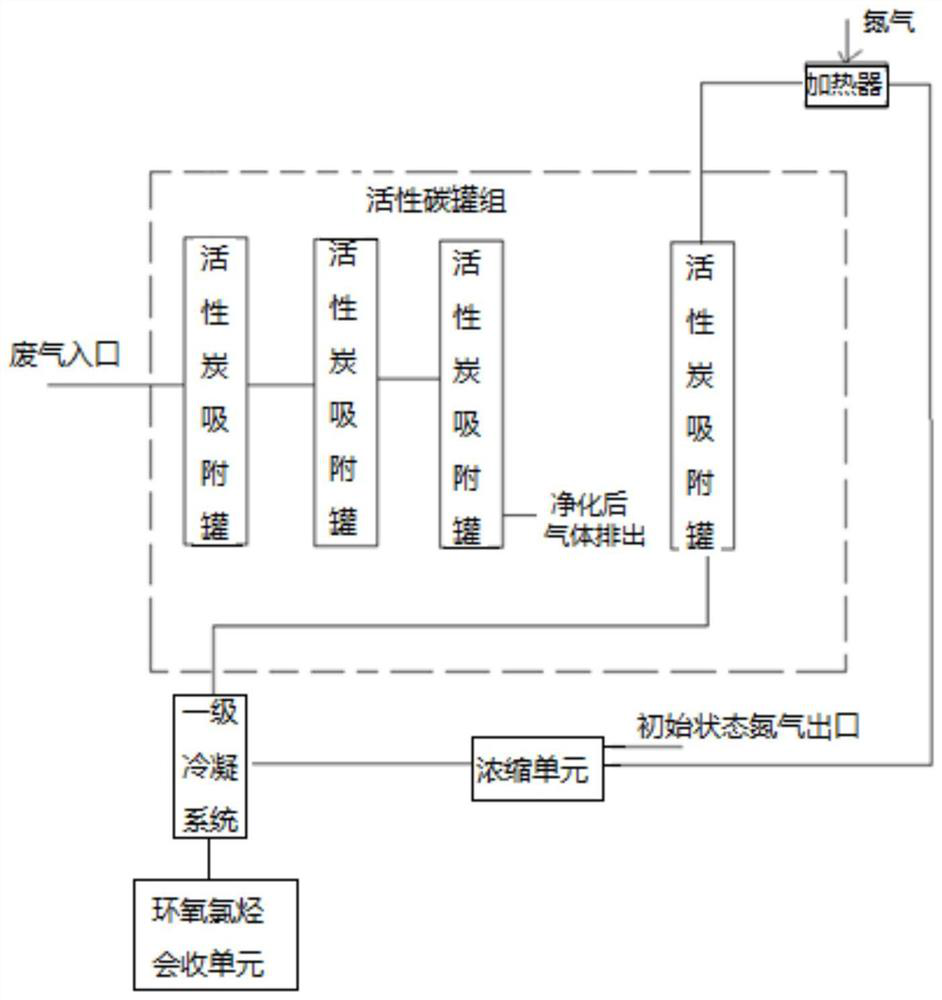

[0063] figure 2 Shown is the schematic diagram of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com