Chitosan/gamma-AlOOH composite thin film for absorbing Pb(II) in water and preparation method and application thereof

A composite film, chitosan technology, applied in the direction of adsorption water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution, difficult product separation, residue, etc. The effect of simple and easy operation in separation and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

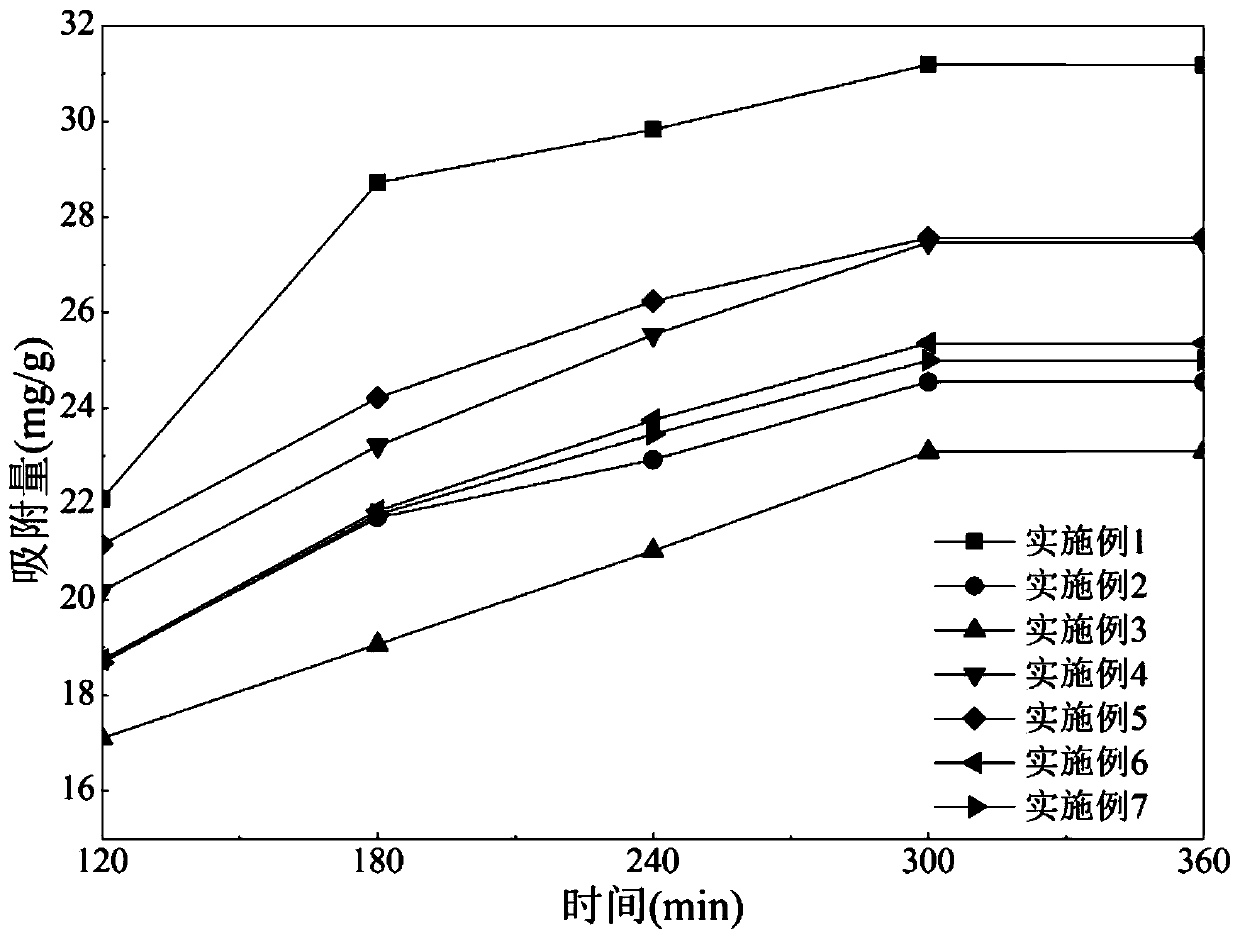

Examples

Embodiment 1

[0038] (1) Dissolve 6.3g aluminum nitrate nonahydrate in 15mL deionized water at room temperature, then slowly add 20mL, 5wt% ammonia water dropwise; the obtained precipitate is centrifugally washed with deionized water until the pH of the filtrate is ≈7, Then the precipitate is dispersed in 30mL of deionized water (the amount of the precipitate is calculated according to the reaction of aluminum nitrate nonahydrate and ammonia water), magnetically stirred at a speed of 500r / min, and 0.305mL of acetic acid and 10g of 5wt% polyvinyl alcohol solution are added successively. After stirring for 1 h at room temperature, it was aged in an oil bath at 90°C for 24 h.

[0039] (2) the γ-AlOOH sol obtained in step (1) is cooled to normal temperature, and then mixed with chitosan sol (2wt%, dissolved in 2v / v% acetic acid aqueous solution) by volume ratio γ-AlOOH sol: chitosan sol = 1 mixed.

[0040] (3) Take 20mL of the mixed sol in step (2), add 1mL of 5wt% glutaraldehyde, stir for 10h...

Embodiment 2

[0044] (1) Dissolve 6.3g aluminum nitrate nonahydrate in 15mL deionized water at room temperature, then slowly add 20mL, 5wt% ammonia water dropwise; the obtained precipitate is centrifugally washed with deionized water until the pH of the filtrate is ≈7, Then disperse the precipitate in 30mL of deionized water, stir it magnetically at a rate of 500r / min, add 0.305mL of acetic acid and 10g of 5wt% polyvinyl alcohol solution in turn, stir at room temperature for 1h, and then age in an oil bath at 90°C for 24h .

[0045] (2) the γ-AlOOH sol obtained in step (1) is cooled to normal temperature, and then mixed with chitosan sol (2wt%, dissolved in 2v / v% acetic acid aqueous solution) by volume ratio γ-AlOOH sol: chitosan sol = 1 mixed.

[0046] (3) Take 20mL of the mixed sol in step (2), add 0.5mL of 5w% glutaraldehyde, stir for 10h, and finally apply the chitosan / γ-AlOOH composite sol on a 2cm×6cm ceramic plate to make it flow After stretching and drying at room temperature for ...

Embodiment 3

[0049] (1) Dissolve 6.3g aluminum nitrate nonahydrate in 15mL deionized water at room temperature, then slowly add 20mL, 5wt% ammonia water dropwise; the obtained precipitate is centrifugally washed with deionized water until the pH of the filtrate is ≈7, Then disperse the precipitate in 30mL of deionized water, stir it magnetically at a rate of 500r / min, add 0.305mL of acetic acid and 10g of 5wt% polyvinyl alcohol solution in turn, stir at room temperature for 1h, and then age in an oil bath at 90°C for 24h .

[0050] (2) the γ-AlOOH sol obtained in step (1) is cooled to normal temperature, and then mixed with chitosan sol (2wt%, dissolved in 2v / v% acetic acid aqueous solution) by volume ratio γ-AlOOH sol: chitosan sol = 1 mixed.

[0051] (3) Get the mixed sol 20mL in the step (2), smear it on the 2cm * 6cm ceramic plate, make it tape casting, and take off the film after drying at room temperature for 48h, obtain the described chitosan / γ-AlOOH composite film.

[0052] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com