Filtering confocal vessel

A confocal and nesting technology, used in material analysis by optical means, laboratory containers, instruments, etc., can solve the problem of sample reduction, inability to maintain the consistency of electric, magnetic or electromagnetic fields, dumping, etc., to save The effect of material and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

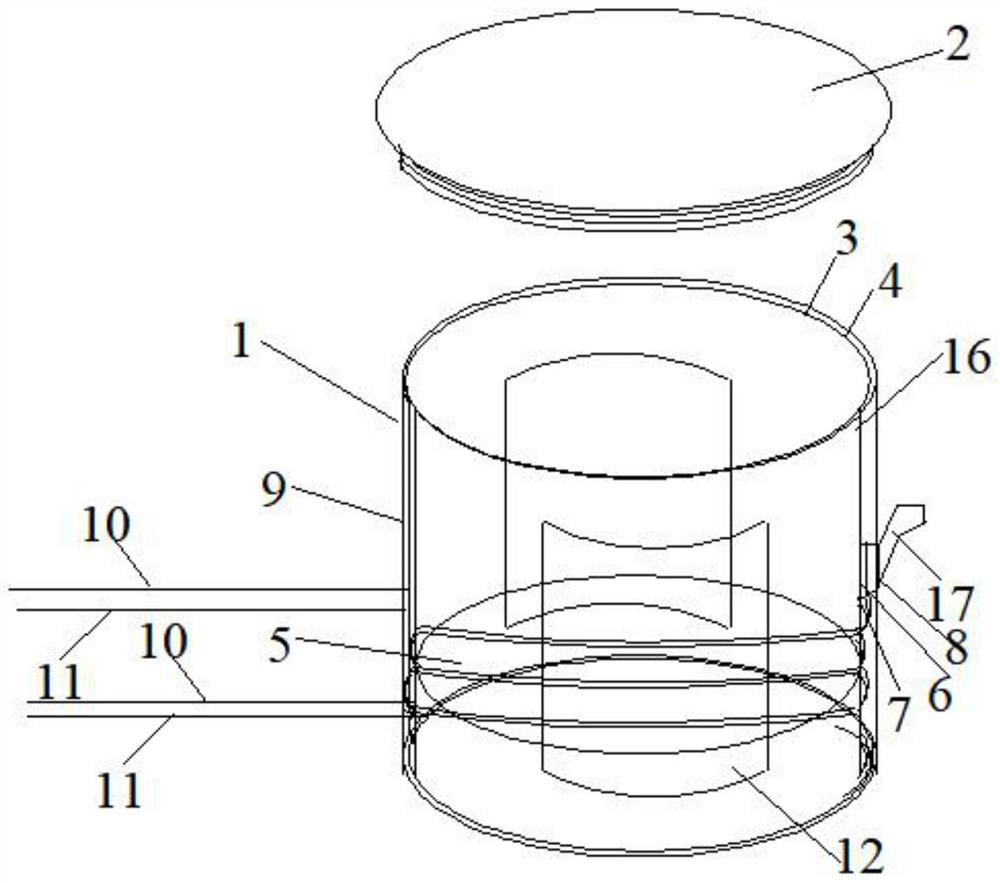

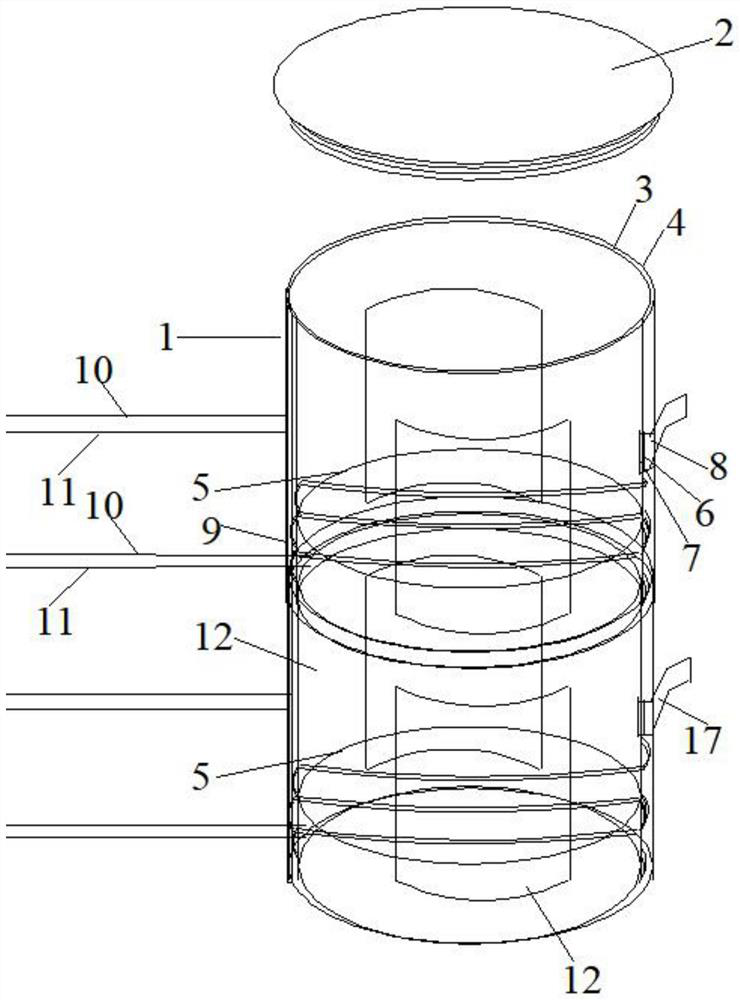

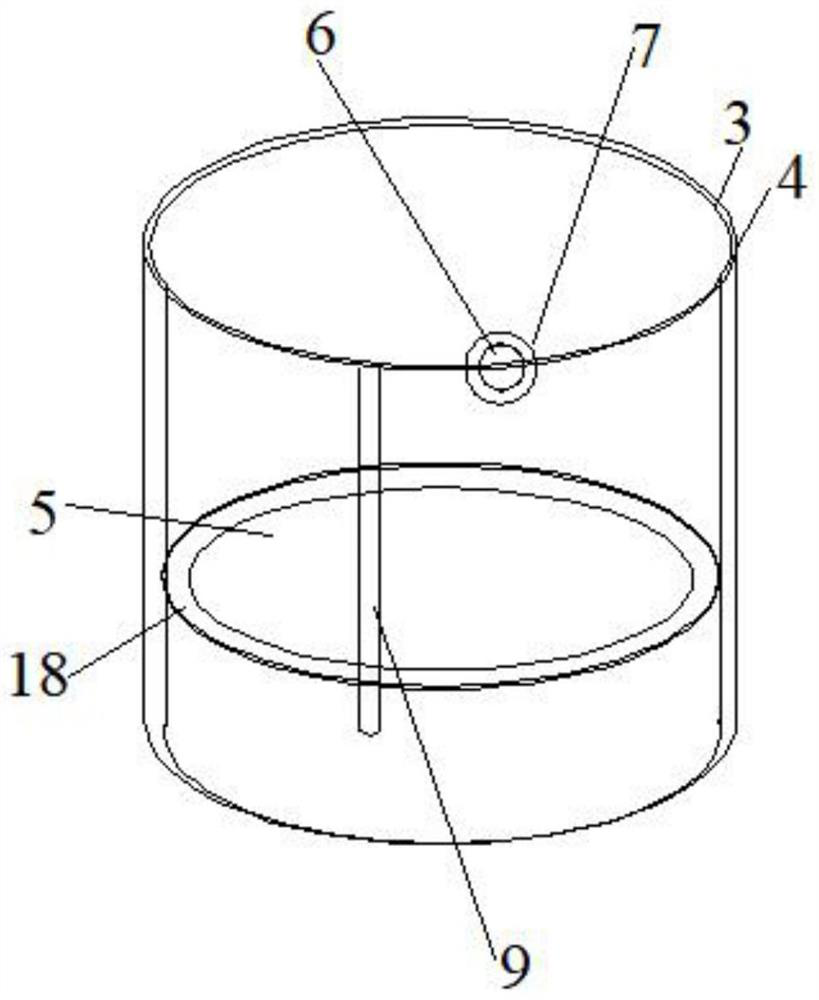

[0032] The filtering confocal dish of this embodiment may include two upper and lower double-layer plastic sleeve dishes, the upper and lower double-layer plastic sleeve dishes have the same structure and size. After the screw connection is completed, cover the top cover on the upper double-layer plastic sleeve and use it together.

[0033] Specifically can be designed as:

[0034] The parameters of the upper double-layer plastic cover and the lower double-layer plastic cover are the same, and both are 50mm high. Among them, the diameter of the inner plate is 50mm, the gap between the inner plate and the outer plate is 10mm, and the height of the glass slide from the bottom of the double-layer plastic cover is 15mm. The thickness is 0.17um, the thread covering length at the upper and lower installation ports is 4mm, the height of the bottom end of the pouring channel from the bottom is 25mm, and its height is 10mm; the electrode plate is an arc with a thickness of 1mm, a heigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com