Spinneret plate for producing hollow suction and discharge filaments

A spinneret and hollow technology, applied in the field of chemical fiber textiles, to achieve good heat dissipation and save material and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

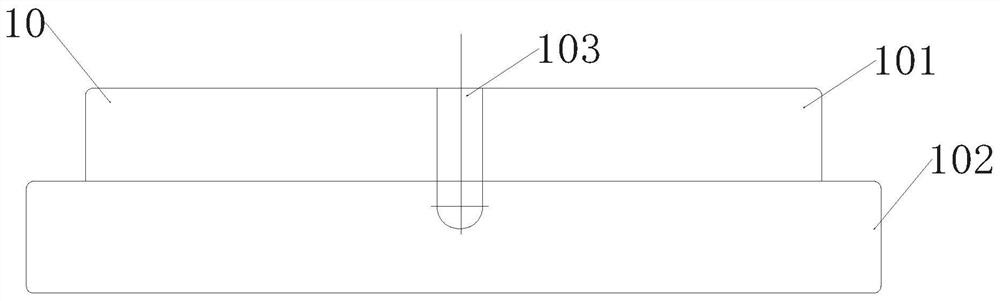

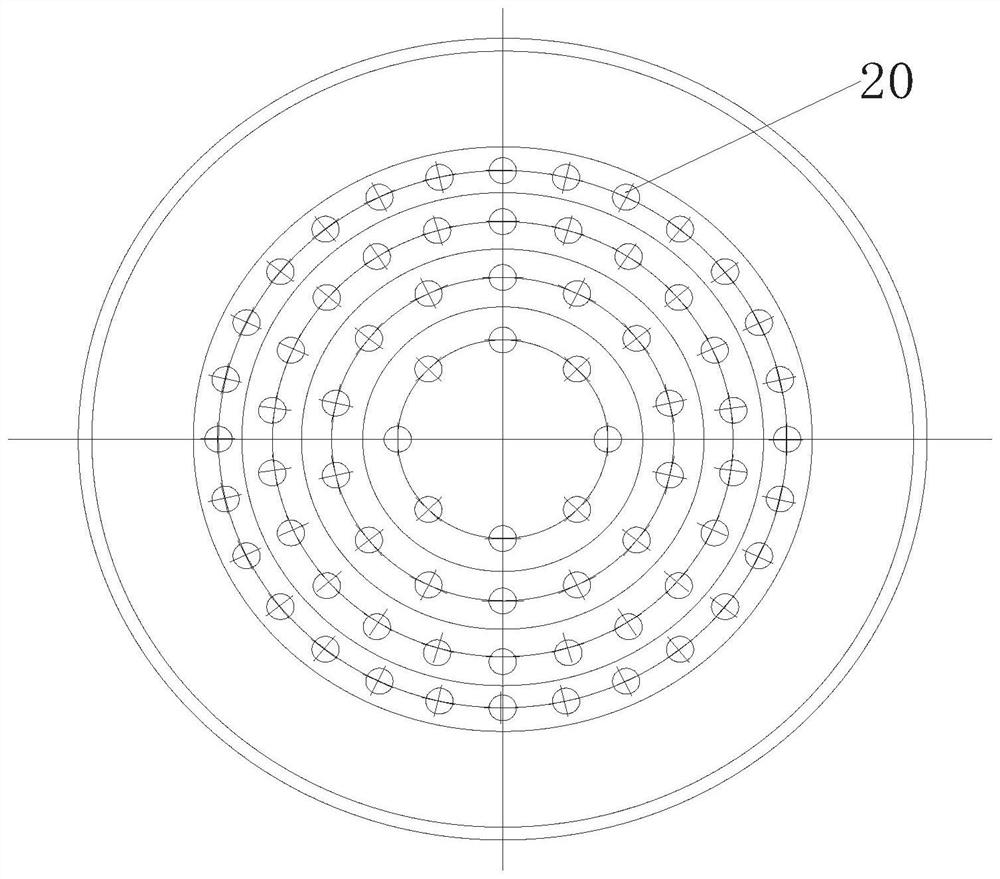

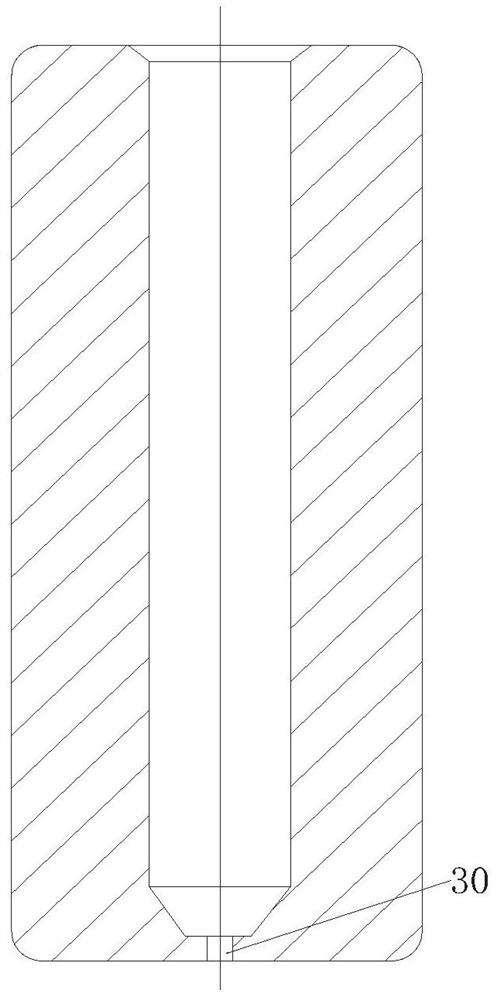

[0032] like Figure 1~3 As shown, it is a schematic structural diagram of a spinneret for the production of a hollow suction and discharge filament in a preferred embodiment of the present invention. A spinnerette for the production of a hollow suction and discharge filament in this embodiment includes a spinneret spinneret 10 , the spinneret spinneret 10 is composed of the first plate body 101, the second plate body 102 and the suction and discharge hole 30 in the hollow suction and discharge hole, the lower end surface of the first plate body 101 and the second The upper end faces of the two plates 102 are fixedly connected.

[0033] The first plate body 101 is provided with a spinneret hole 20, the upper end of the spinneret hole 20 is provided with a chamfer, and the lower end of the spinneret hole 20 is smaller than the diameter of the middle section, and the upper end of the spinneret hole 20 is The lower end is provided with a hollow suction and discharge hole 30 in th...

Embodiment 2

[0038] like Figure 5-6 As shown, it is a schematic structural diagram of a spinneret for the production of hollow suction and discharge of another preferred embodiment of the present invention. The spinneret for the production of a hollow suction and discharge of the present embodiment is added in Example 1. The replaceable structure 40 is installed on the upper end of 102 , and the replaceable structure 40 includes a third plate 404 and a hole 402 .

[0039] The third plate body 404 is provided with a plurality of threaded holes, the outer wall of the hole body 402 is provided with threads, and the top of the hole body 402 is provided with a hexagonal hole 403 , and the hexagonal hole 403 communicates with 20 .

[0040] In this embodiment, through the threaded connection between the hole body 402 and the threaded hole 401, the effect that each 20 can be replaced at any time is achieved. When a certain 20 is damaged, it is more convenient to replace which one needs to be repl...

Embodiment 3

[0042] The present invention also provides a special process for hollow filament suction and discharge including:

[0043] By making a special double C-type spinneret, using a special process in the process of producing recycled fibers, after many times of research, the discarded plastic bottles are dried at a drying temperature of 150°C for 6 hours, and then melted at a temperature of 270-290°C During the process, filter twice to remove impurities, control the viscosity of the melt IV=0.692+ / -0.05, melt spinning, pass through the assembly (assembly pressure of 0.18-0.21mpa) equipped with a custom spinneret and blow through the blower The temperature is 25°C, the wind speed is 0.75+ / -0.05M / S, the fiber is cooled to the status of '8', and the POY yarn is produced at a speed of 2500m / min, and the temperature is 25°C, and the humidity is 40%. Remove the stress of the tow, and then add and eject the DTY75D / 48F spinning '8' hollow fiber at a speed of 500-550m / min on the texturing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com