Heat dissipation assembly, heat dissipation method and heat dissipation device

A heat-dissipating component and technology to be dissipated, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problem of poor heat-dissipation capability of heat-dissipating components, achieve precise adjustment, improve heat-dissipation capability, and simple adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

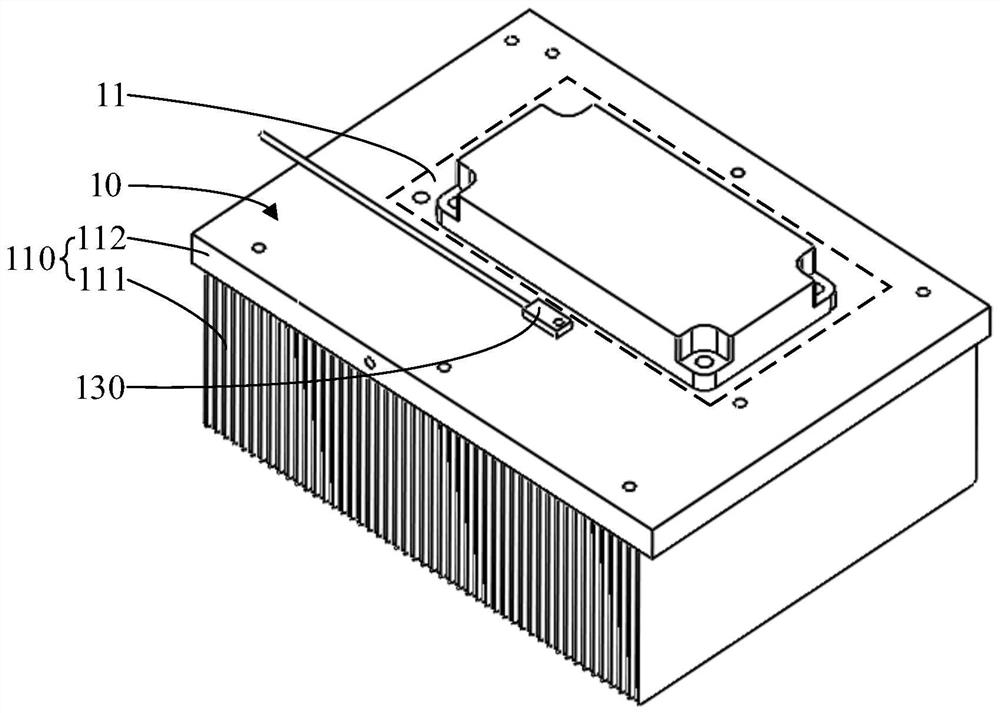

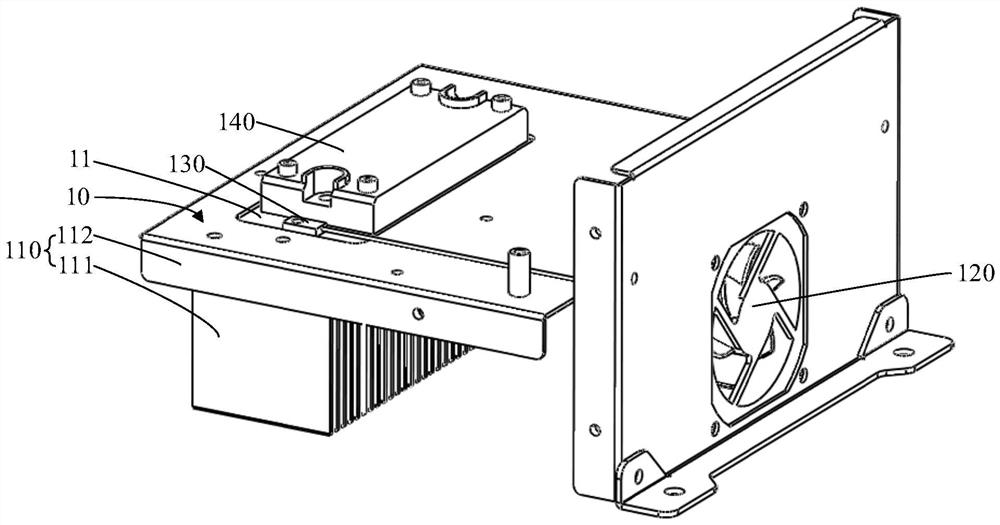

[0023] It can be known from the background art that the current heat dissipation components have the problem of poor heat dissipation capability.

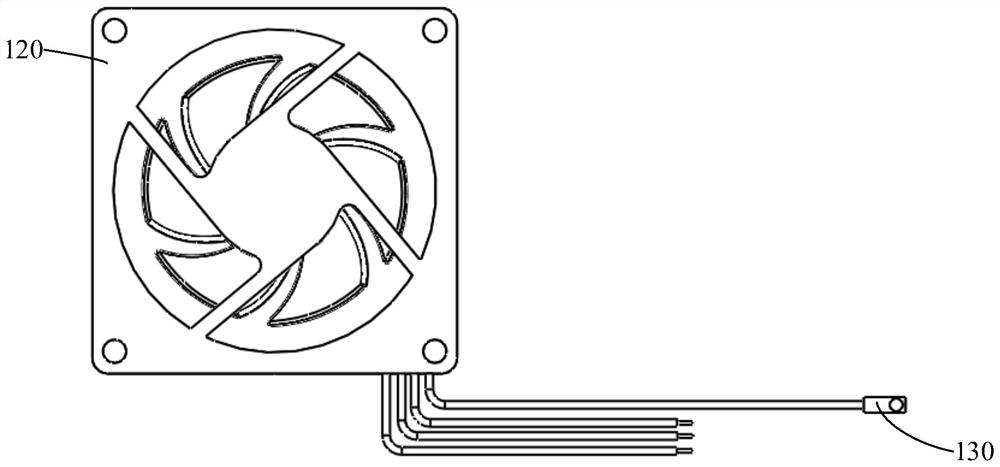

[0024] The analysis found that one of the reasons for the poor heat dissipation capacity of the current heat dissipation components is that at present, with the large-scale application of device integration, the area of the device is getting smaller and smaller. The heat is taken away, and the wind speed of the fan needs to be increased. However, the increase in the wind speed of the fan means the corresponding increase in the speed and noise of the fan. In order to meet the cooling requirements and improve the noise of the fan, the speed of the fan needs to be adjusted according to different device temperatures, so that the device temperature When lower, the fan can reduce the speed, thereby reducing the noise. However, the current fan usually uses a frequency converter to adjust the speed of the fan, and the board circuit of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com