Method for improving quality of tobacco leaves by using kvass fermented tobacco leaves

A technology of kvass and tobacco leaves, applied in the field of using kvass fermented tobacco leaves to improve the quality of tobacco leaves, can solve the problems of lack of aroma, heavy miscellaneous gas in tobacco leaves, less reports, etc., and achieve improvement in aftertaste and burning characteristics, and change in miscellaneous gas and irritation. Weak, aroma richness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

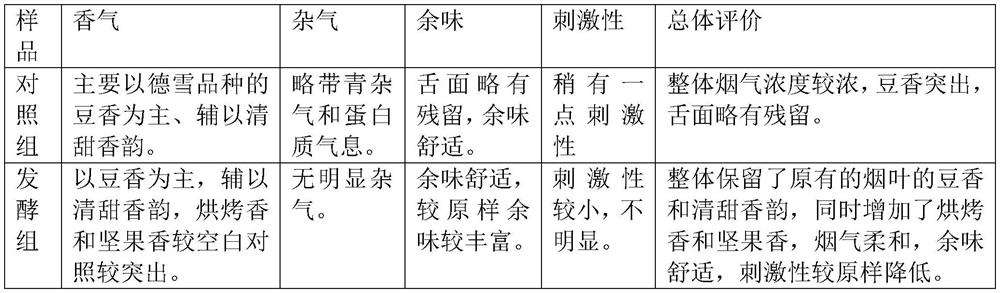

[0017] Prepare 300g of Dexue No. 1 upper grade 2 cigar leaves, mix 2.5mL of Kvass concentrate and 47.5mL of deionized water to prepare a mixed solution, spray the mixed solution evenly on the surface of the cigar leaves, and then put the leaves into a burlap bag middle. Put the burlap bag into a constant temperature and humidity incubator for fermentation, and the fermentation conditions are as follows: the fermentation humidity is 75%, the temperature is 35°C, and the fermentation period is 30 days. After the fermentation, the moisture balance of the tobacco leaves was carried out until the moisture content of the tobacco leaves was 17±1%, and then the tobacco leaves were rolled into cigarettes, and professional evaluation personnel were organized to conduct sensory evaluation. The results are shown in Table 1.

[0018] In addition, the mixed solution was replaced with pure water, and the blank control group experiment was carried out according to the same procedure.

[0019...

Embodiment 2

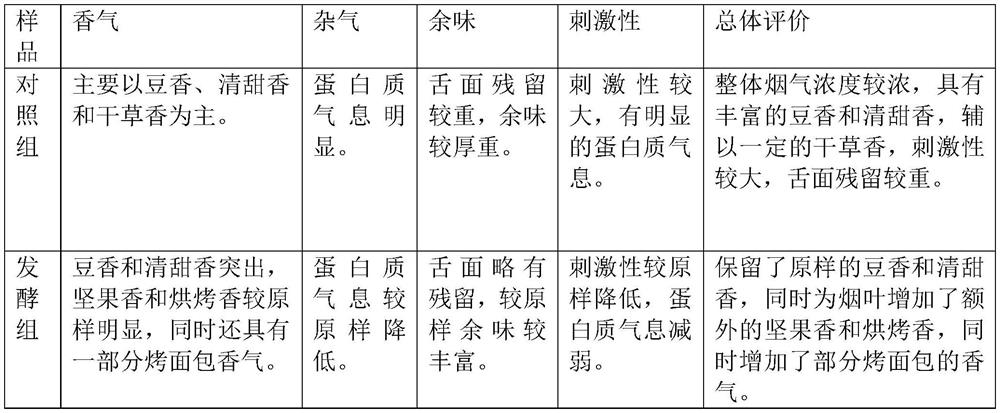

[0023] Prepare 300g of Dexue No. 3 upper grade 2 cigar leaves, mix 2.5mL of Kvass concentrate and 47.5mL of deionized water to prepare a mixed solution, spray the mixed solution evenly on the surface of the cigar leaves, and then put the leaves into a burlap bag middle. Put the burlap bag into a constant temperature and humidity incubator for fermentation, and the fermentation conditions are as follows: the fermentation humidity is 75%, the temperature is 35°C, and the fermentation period is 30 days. After the fermentation, the moisture balance of the tobacco leaves was carried out until the moisture content of the tobacco leaves was 17±1%, and then the tobacco leaves were rolled into cigarettes, and professional evaluation personnel were organized to conduct sensory evaluation. The results are shown in Table 2.

[0024] In addition, the mixed solution was replaced with pure water, and the blank control group experiment was carried out according to the same procedure.

[0025...

Embodiment 3

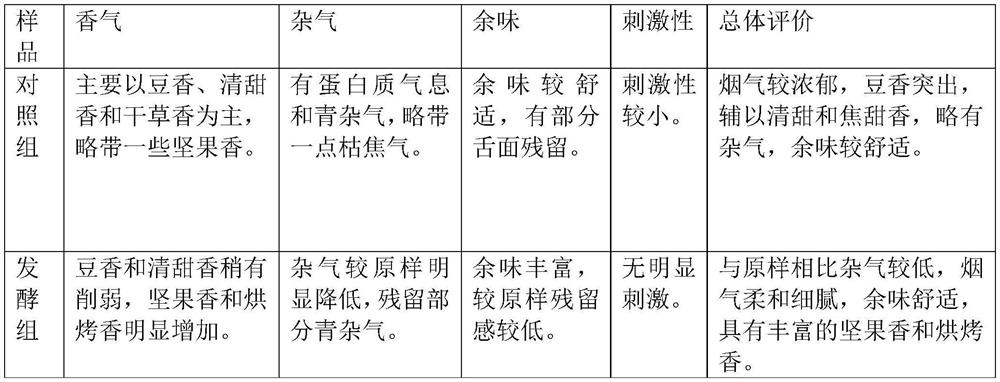

[0029] To prepare 300g of Dexue No. 4 upper grade 2 cigar leaves, mix 2.5mL of Kvass concentrate and 47.5mL of deionized water to prepare a mixed solution, spray the mixed solution evenly on the surface of the cigar leaves, and then put the leaves into the sackcloth in the bag. Put the burlap bag into a constant temperature and humidity incubator for fermentation, and the fermentation conditions are as follows: the fermentation humidity is 75%, the temperature is 35°C, and the fermentation period is 30 days. After the fermentation, the moisture balance was carried out until the moisture content of the tobacco leaves was 17±1%, and then the tobacco leaves were rolled into cigarettes, and professional evaluation personnel were organized to conduct sensory evaluation. The results are shown in Table 3.

[0030] In addition, the mixed solution was replaced with pure water, and the blank control group experiment was carried out according to the same procedure.

[0031] Table 3 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com