Novel clinical medicine metering device for department of pediatrics

A technology for using drugs and dispensers, which is applied in the field of pediatric clinical drug dispensers. It can solve the problems of inaccurate doses and inconvenient large quantities of liquid drug doses. It achieves convenience in volume, improves practical value, and avoids different drug concentrations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

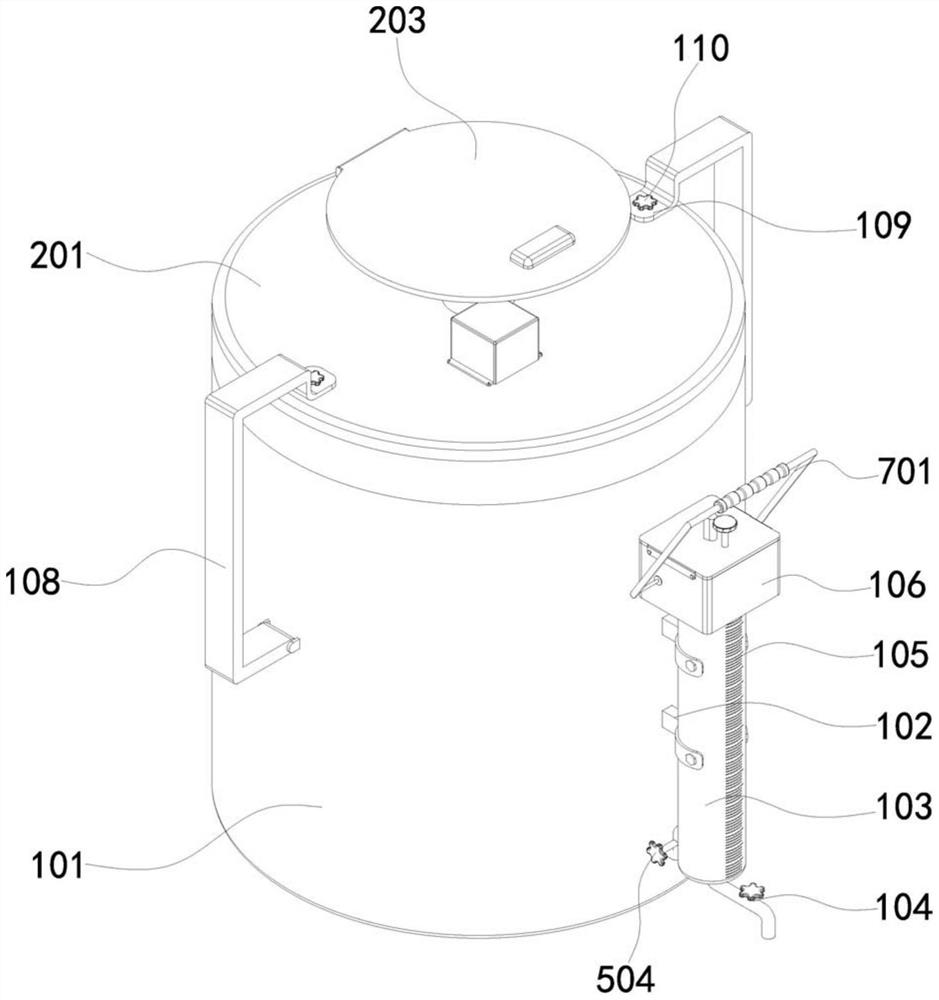

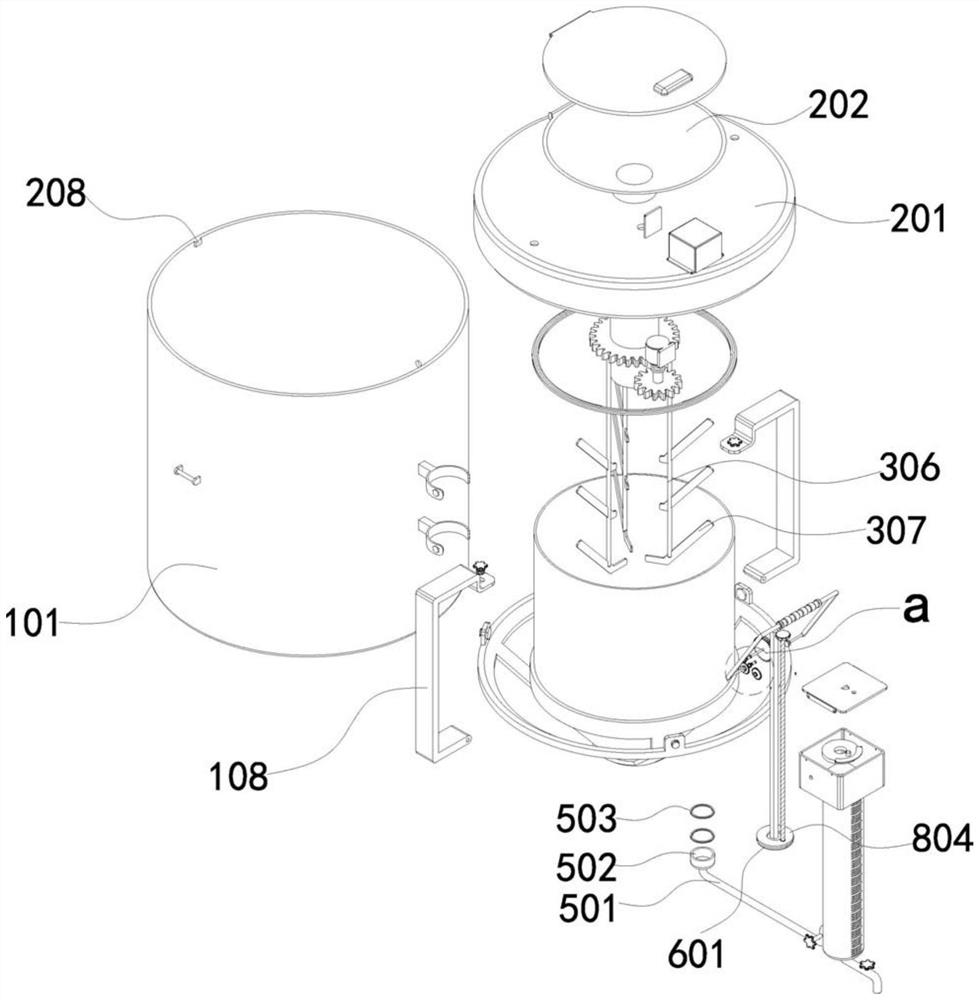

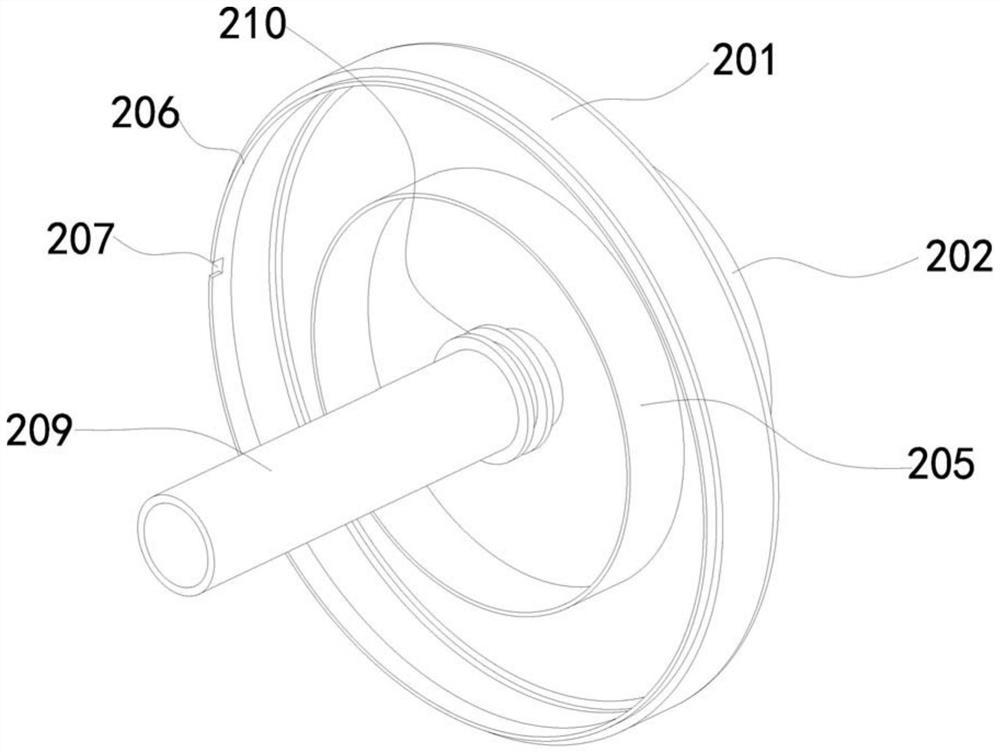

[0029] like Figure 1 to Figure 7 As shown, the present invention provides a novel pediatric clinical medicine doser, comprising a mounting shell 101, a drug storage cartridge 401 connected by a support assembly is arranged in the mounting shell 101, and one side of the mounting shell 101 is provided with a through- The measuring cylinders 103 are installed on the two sets of fixing racks 102. The measuring cylinders 103 are made of transparent material. A scale line 105 is provided on one side of the measuring cylinders 103. 501 is provided with a first one-way valve 504, and the bottom of the measuring cylinder 103 is provided with a second one-way valve 104.

[0030] When the medicine doser is in use, a larger volume of medicinal liquid can be stored in the storage cartridge 401. Since the storage cartridge 401 is connected with the measuring cylinder 103, the medicinal liquid can be entered into the measuring cylinder 103 through the first one-way valve 504 first. After m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com