Guide rail structure and chip testing machine

A technology of guide rail and driving mechanism, which is applied in the field of mobile guide rail and can solve problems such as displacement and deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

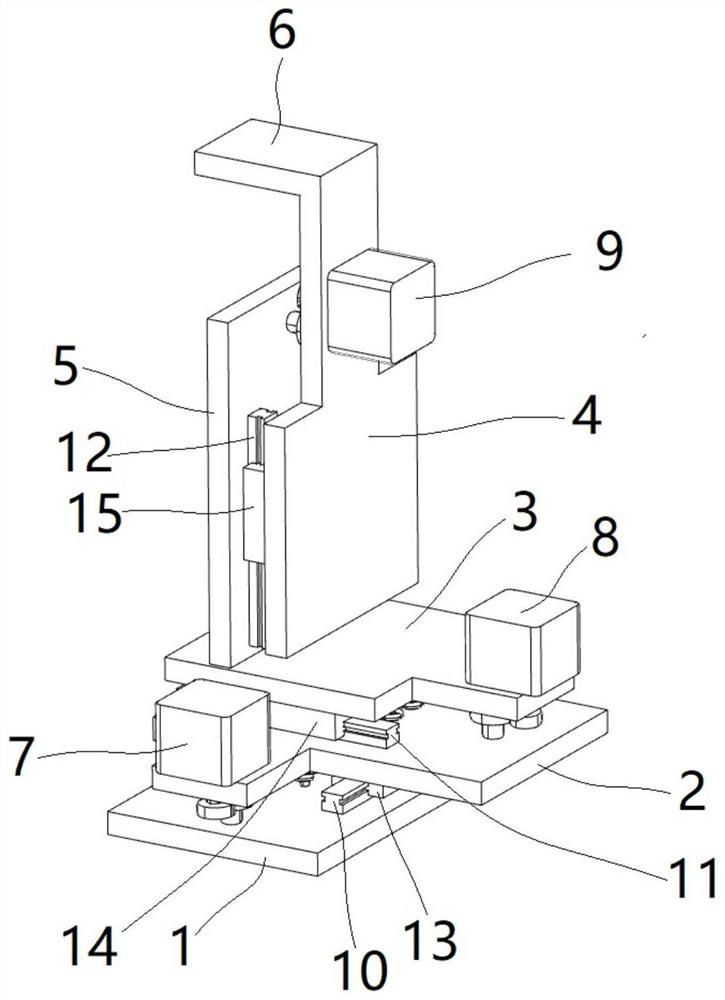

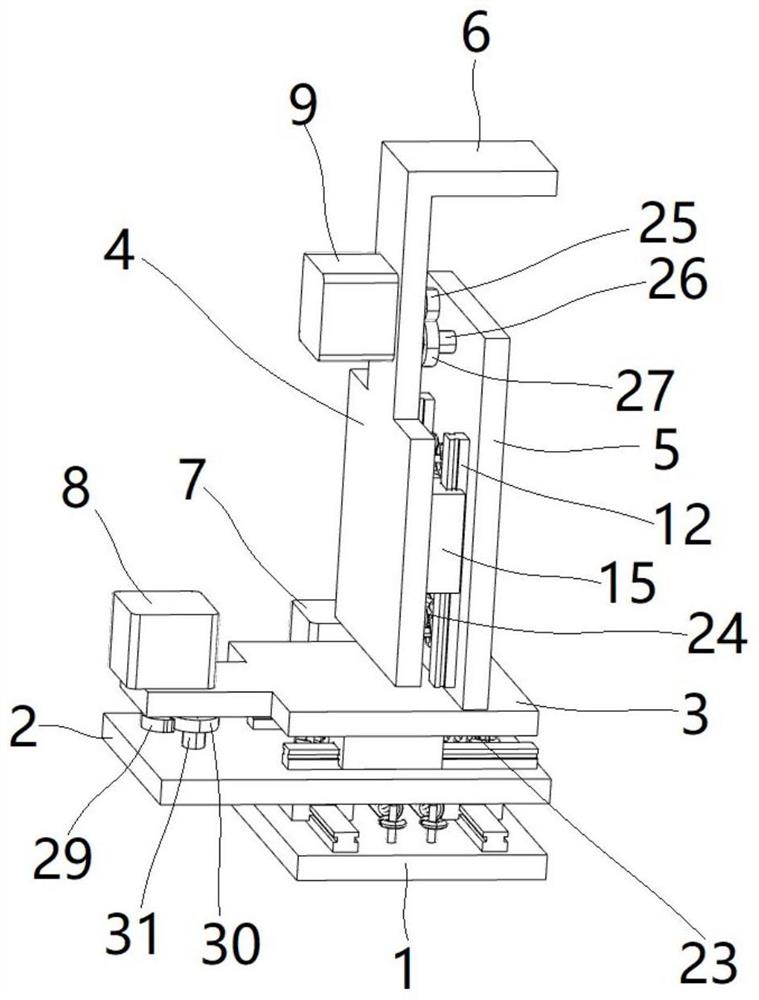

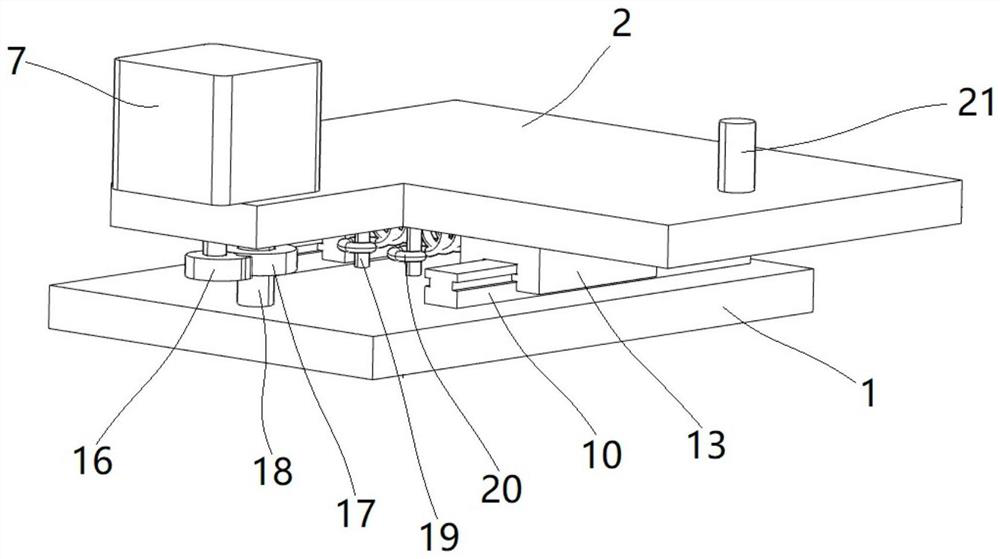

[0048] This embodiment provides a specific implementation of the guide rail structure, such as figure 1 and figure 2 As shown, it includes a mounting platform 1, a first substrate 2, a second substrate 3 and a third substrate 4. The first substrate 2 is slidably mounted on the mounting platform 1, the second substrate 3 is slidably mounted on the first substrate 2, and the third substrate 3 is slidably mounted on the first substrate 2. The base plate 4 is slidably mounted on the second base plate 3 , and a mounting portion 6 suitable for installing the positioning member protrudes from the third base plate 4 , and the sliding direction of the first base plate 2 , the sliding direction of the second base plate 3 and the third The sliding directions of the substrates 4 are perpendicular to each other. The first base plate 2 is provided with a first drive mechanism, and the drive end of the first drive mechanism is connected to the mounting platform 1; the second base plate 3 i...

Embodiment 2

[0065] This embodiment provides a specific implementation of a chip testing machine, including the guide rail structure in Example 1, the guide rail structure is installed on the testing machine, and an alignment member is installed on the mounting portion 6 on the guide rail structure, so that the The positioner adjusts the position and angle of the chips on the slide table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com