Low-cost full-automatic stand column stacking machine

A fully automatic, low-cost technology, applied in the field of palletizers, can solve the problems of low cost, unfavorable popularization and use, and large space occupation, and achieve the effects of high work efficiency, easy popularization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

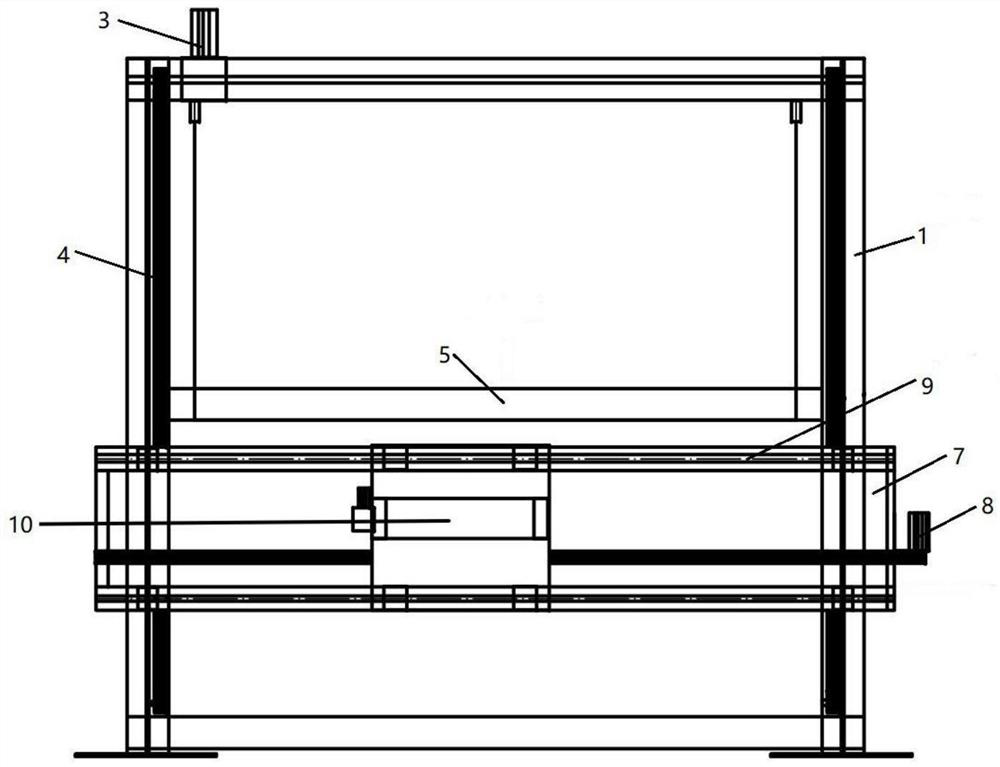

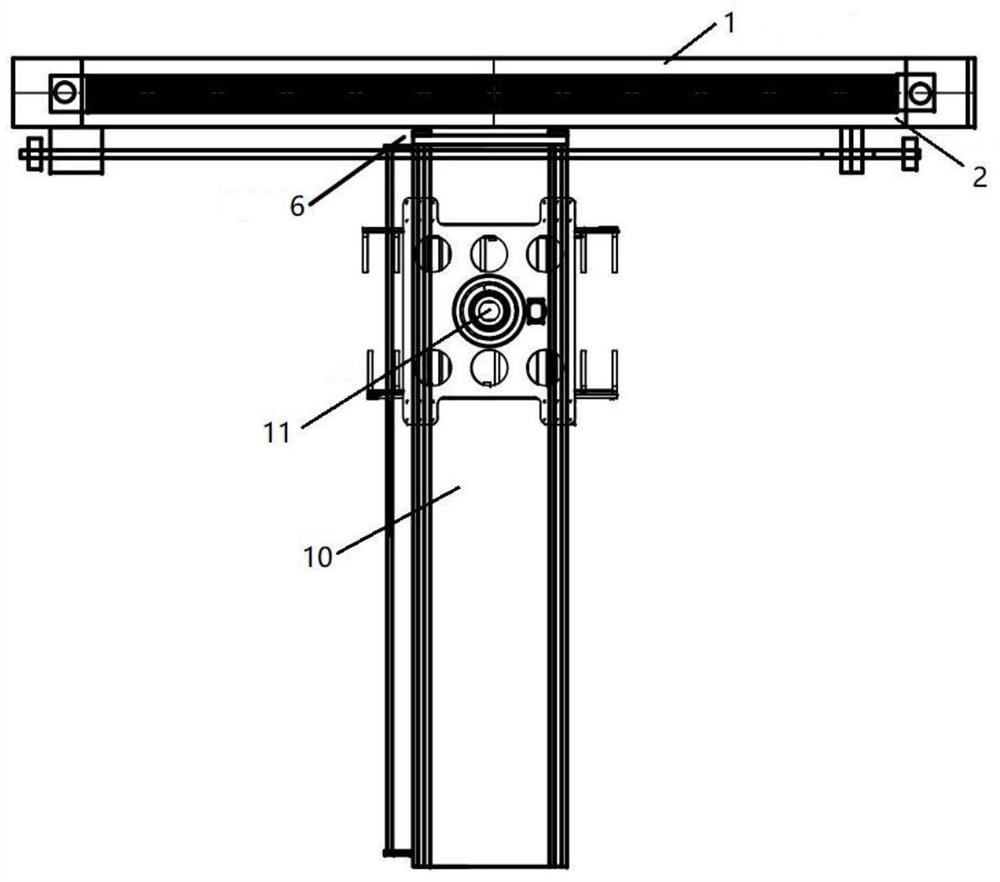

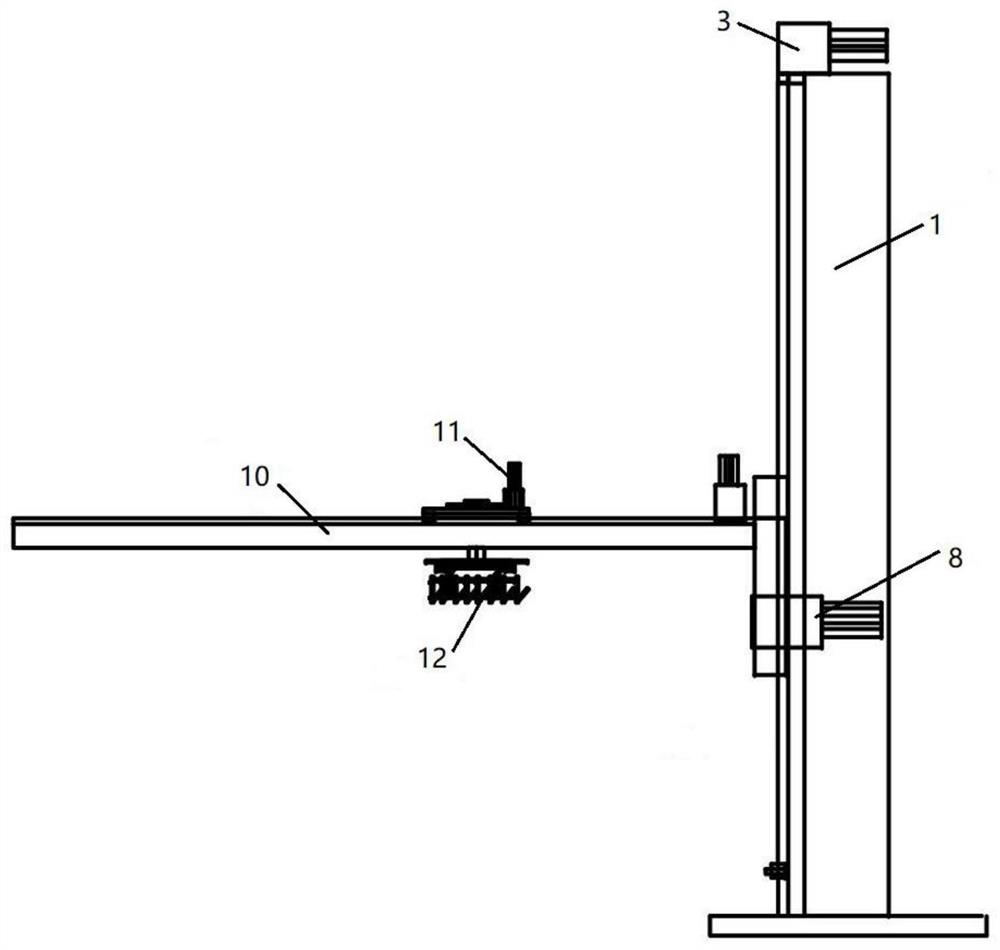

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] A low-cost fully automatic column stacker includes a frame 1 on which a vertical assembly 2 is installed, and the vertical assembly 2 includes a vertical slide motor 3, a vertical slide 4. Vertical slider, vertical counterweight 5 and horizontal assembly 6, the vertical slide motor 3 is installed on the top of the rack 1, and the vertical slide motor 3 drives the vertical slide 4 The vertical slider moves up and down, the horizontal assembly 6 is connected to the vertical slider, the horizontal assembly 6 is connected to the vertical counterweight 5 through a chain, and the horizontal assembly 6 includes a horizontal frame 7, a horizontal The sliding rail motor 8 , the transverse sliding rail 9 , the transverse sliding block and the longitudinal assembly 10 , the transverse sliding rail motor 8 is installed at one end of the transverse frame 7 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com