Anti-collision guardrail and construction method thereof

A technology of anti-collision guardrails and guardrails, which is applied in the field of bridge engineering, and can solve the problems of the durability of the connection structure of prefabricated concrete anti-collision guardrails to be tested, the welding quality is difficult to control, and the precision of prefabricated installation is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

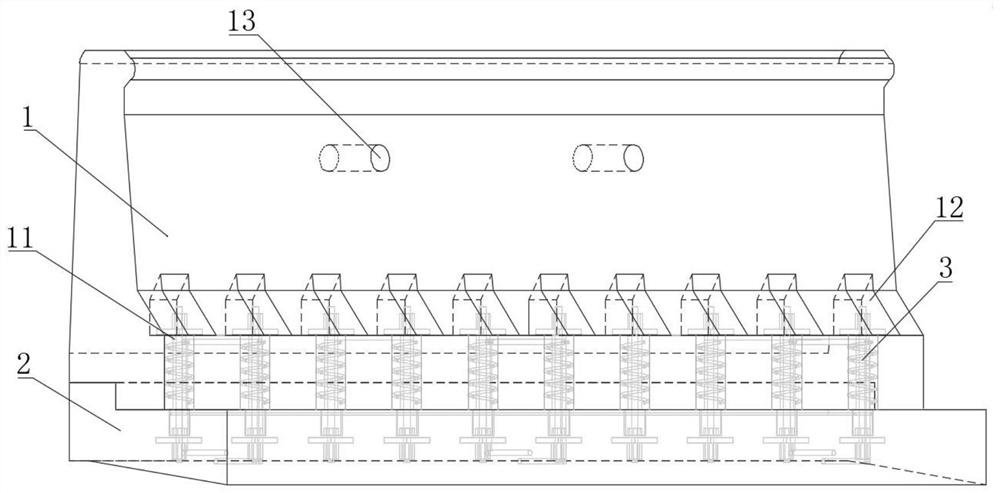

[0051] Example 1: as Figure 1-2 As shown, an embodiment of an anti-collision guardrail disclosed in the present invention includes:

[0052] Guardrail 1, bridge deck 2 and connecting structure 3;

[0053] The upper surface of the bridge deck 2 is provided with a multi-level ladder structure. The bottommost level of the multi-level ladder structure is a connecting ladder. A plurality of connecting structures 3 are inlaid on the stepped surface of the connecting ladder. The lower end surface of the guardrail 1 is connected to the bridge deck. The multi-level ladder structure of 2 is matched and connected through the connecting structure 3;

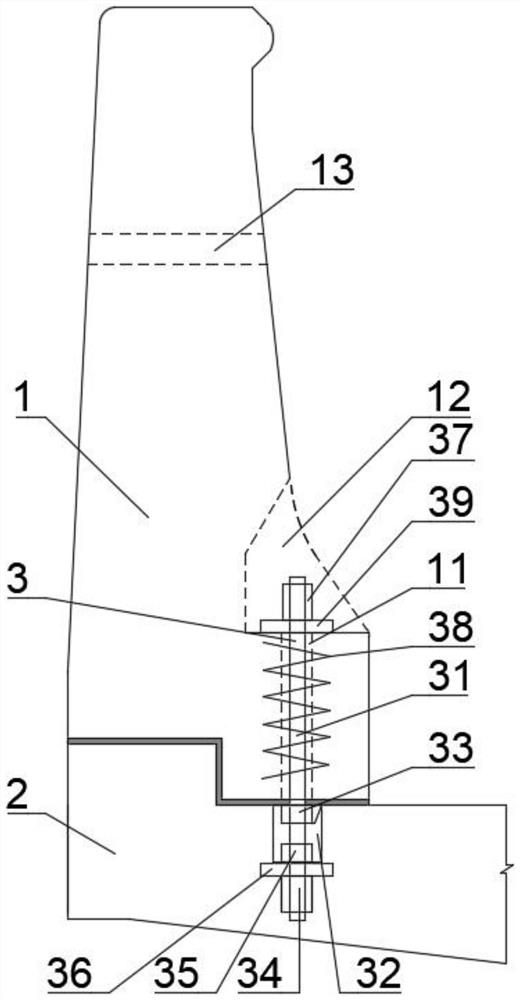

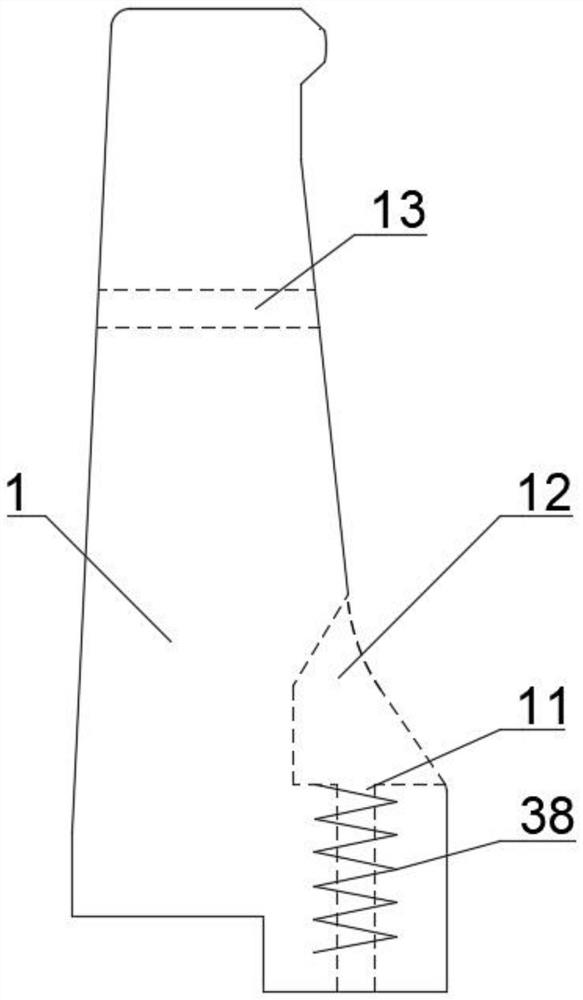

[0054] The connecting structure 3 includes a screw 31, a sleeve 32 and an eccentric nut 33. The sleeve 32 is a cylindrical structure with a closed bottom and an open top. The sleeve 32 is vertically embedded in the stepped surface of the connecting ladder. The top of the sleeve 32 is The open end is not higher than the step surface of the...

Embodiment 9

[0076] Example 9, as Figure 8-15 As shown, a construction method of a crash barrier includes the following steps:

[0077] The guardrail 1 and the bridge deck 2 are prefabricated respectively; when the bridge deck 2 is prefabricated, the steel formwork formwork is used to form the bridge deck formwork, the lower part of the connection structure 3 is embedded, and concrete is poured into the bridge deck 2 formwork, so that the upper surface of the bridge deck 2 is formed. Multi-level ladder structure, and make the lower end part of the connection structure 3 pre-buried on the first-level ladder located at the bottom of the multi-level ladder structure; when prefabricating the guardrail 1, use the steel formwork formwork to form the guardrail formwork, and pour concrete to make the guardrail 1 The lower end surface of the bridge plate 2 forms a structure adapted to the multi-level stepped structure on the upper surface of the bridge deck 2;

[0078] Assemble the guardrail 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com