Snakelike concrete crack treatment equipment and use method

A technology for processing equipment and concrete, used in construction, building maintenance, building construction, etc., can solve problems such as time-consuming and labor-intensive crack grinding, high crack cleaning requirements, and unsolved crack problems. The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

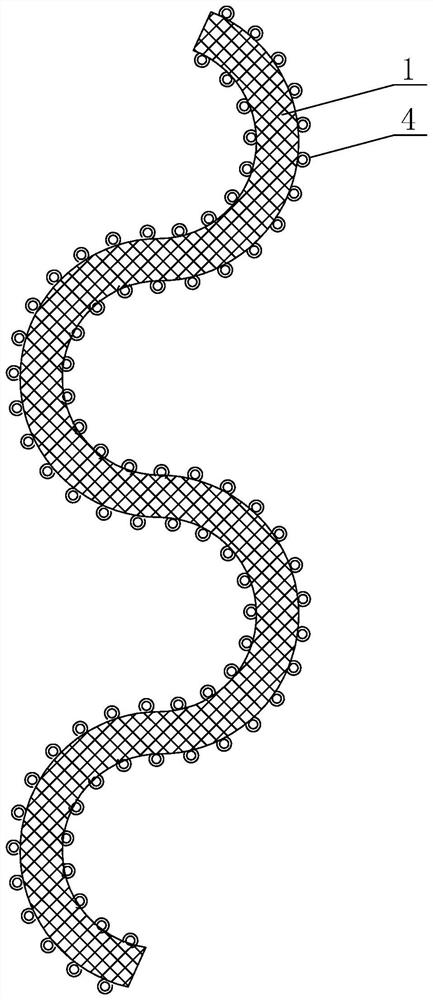

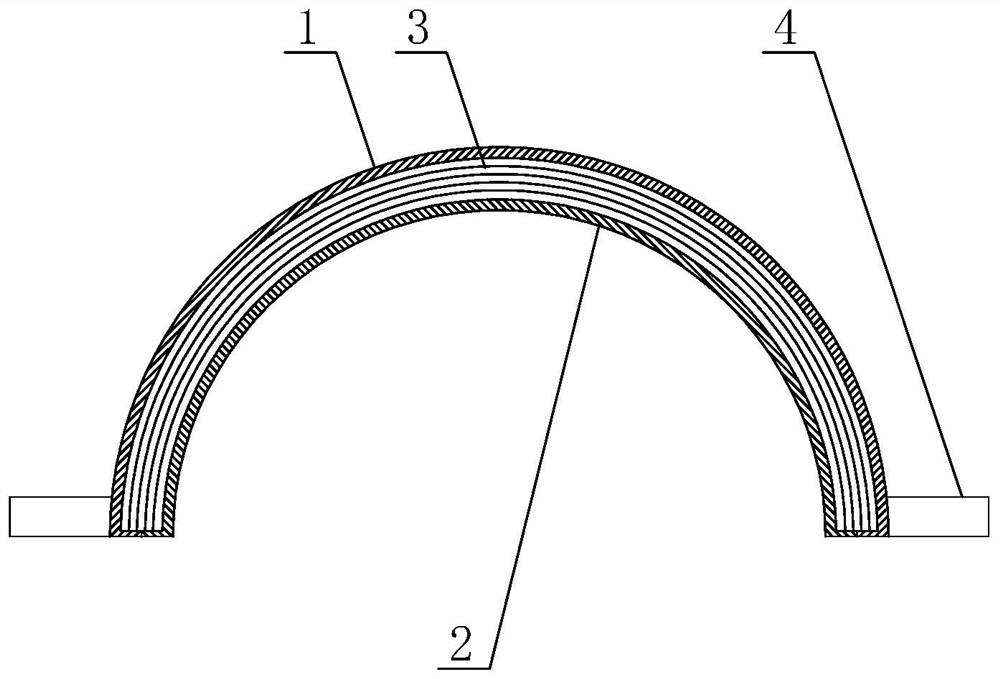

[0026] Example 1: as attached Figure 1-2 The invention is a serpentine concrete crack treatment equipment, including a double-layer steel mesh body, the double-layer steel mesh body can be bent according to the shape of the serpentine concrete crack, and the double-layer steel mesh body can be folded into a serpentine concrete crack The main body of the double-layer steel mesh includes an upper steel mesh 1 and a lower steel mesh 2. Preferably, the pores of the upper steel mesh 1 and the lower steel mesh 2 are 2-3 mm. The upper wire mesh 1 and the lower wire mesh 2 are fixedly connected, and the upper wire mesh 1 and the lower wire mesh 2 form a closed cavity, and the closed cavity is filled with several layers of glass ribbons 3 soaked in epoxy resin, preferably Yes, the number of layers of the glass ribbon 3 is 3-6 layers.

[0027] Further, the cross section of the double-layer steel mesh body is in a semi-circular arc shape, so that the double-layer steel mesh body has a ...

Embodiment 2

[0030] Embodiment 2: the present invention is a kind of using method of serpentine concrete crack treatment equipment, including steps:

[0031] S1. Carve out both sides of the concrete crack to form crack grooves, and grind the crack grooves;

[0032] 2-5cm on both sides of the concrete crack can be chiseled, the depth is 1.5-2cm, the specific size is determined according to the actual situation, and the width of the concrete crack groove is smaller than the width of the main body of the double-layer steel mesh.

[0033] S2. Clean up the crack groove, and clear the debris, dust, etc. in the crack groove;

[0034] S3. According to the shape of the crack groove, the main body of the double-layer steel mesh is bent into the shape of the crack groove;

[0035] S4, buckle the main body of the semi-circular double-layer steel mesh in the crack groove, and fix the main body of the double-layer steel mesh in the crack groove through steel nails;

[0036] After the main body of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com