Supporting structure in PBA method pilot tunnel and construction method of supporting structure

A supporting structure and construction method technology, applied in the direction of infrastructure engineering, excavation, sustainable waste treatment, etc., can solve problems such as easy cracking, non-degradable, difficult drilling and cutting, etc., to achieve reduced compressive strength, good waterproof performance, Good soil retaining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

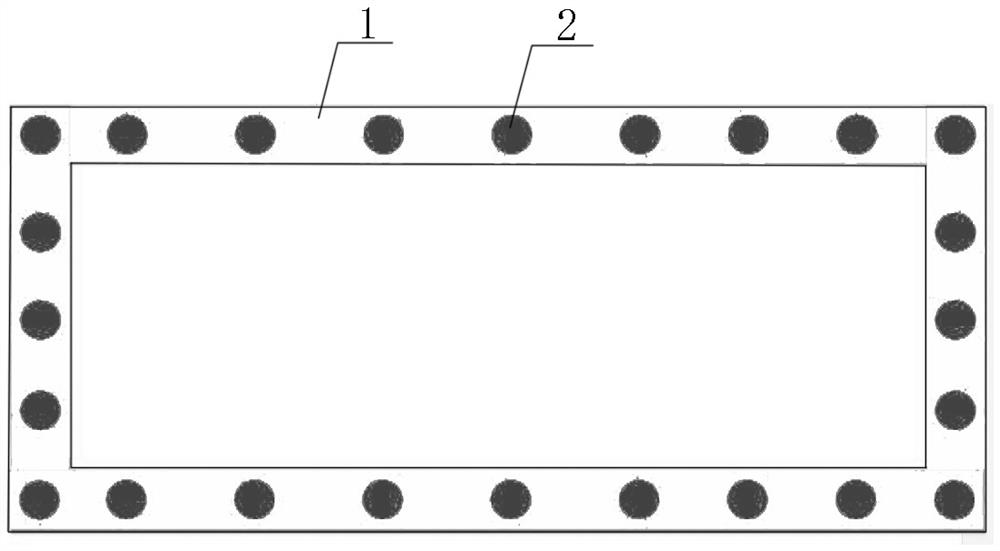

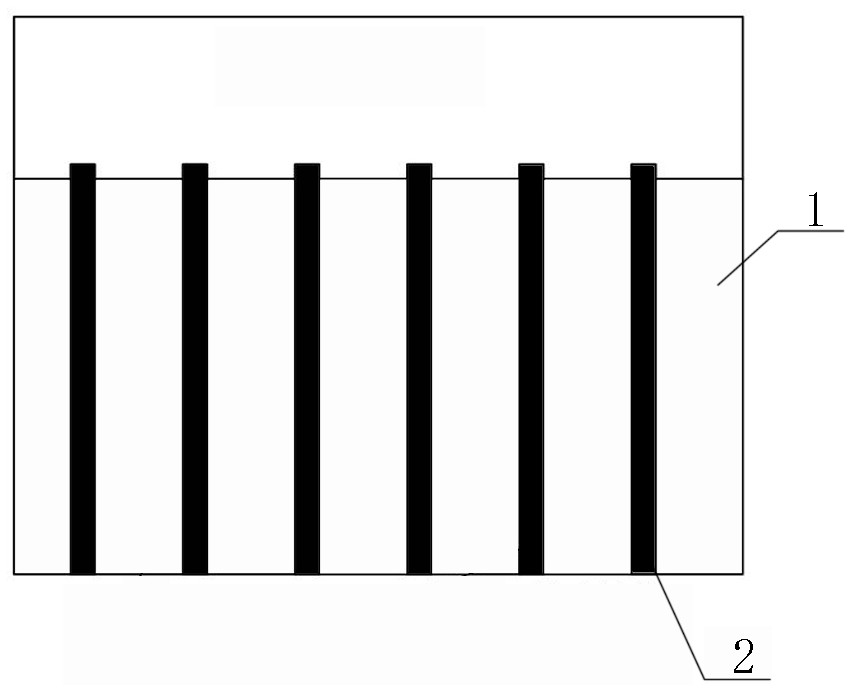

[0068] After the initial support of the PBA small guide, the position of the continuous wall (1) is labeled in the design position, and the bottom plate is sprayed with the concrete. Welding vertical direction, which is integrated into wholehearters, spray concrete and steel grille → preparing toughness, low-intensity regeneration concrete → using a drill to dig off the soil of continuous walls, and reach the design elevation, pouring toughness Low-intensity regeneration concrete, forming a continuous wall (1) → in accordance with the design requirements, labeled the position of the drilling pile (2) → Drilling the drilling pile (2) at the labeling of the drilling machine → Place the steel cage at the hole position, pouring steel regenerative concrete to form a drilling pile (2).

[0069] The preparation method of toughness and low strength regeneration concrete is as follows:

[0070] 1) Determine the water as a 4: 1

[0071] 2) Material preparation

[0072] (1) Main gel material...

Embodiment 2

[0082] Unlike Example 1, the preparation method of low strength regeneration concrete in this embodiment is different, and the rest are the same as in Example 1.

[0083] The method for preparing low-strength regeneration concrete in this embodiment is:

[0084] 1) Determine the water as a 3: 1

[0085] 2) Material preparation

[0086] (1) Main gel material, bentonite, fly ash, basalt fiber and other raw material acceptance meet quality requirements; aggregate uses crusher to break the abandoned concrete block in the factory or construction site, using the vibrating screen to sort, thick The aggregate particles are 5 to 30 mm, which may be circular, angular, and the like; the fine aggregate size is 0.1 to 5 mm.

[0087] (2) Determination of main gel material, additional components, aggregate, and additives, and the amount of gel material is 140 kg / m based on the weight ratio of the water as average ratio. 3 The amount ratio of cement and lime is 1: 0.75, that is, cement 80kg / m...

Embodiment 3

[0096] Unlike Example 1, the preparation method of low strength regeneration concrete in this embodiment is different, and the rest are the same as in Example 1.

[0097] The method for preparing low-strength regeneration concrete in this embodiment is:

[0098] 1) Determine the water as average ratio of 2: 1

[0099] 2) Material preparation

[0100] (1) Main gel material, bentonite, fly ash, basalt fiber and other raw material acceptance meet quality requirements; aggregate uses crusher to break the abandoned concrete block in the factory or construction site, using the vibrating screen to sort, thick The aggregate particles are 5 to 30 mm, which may be circular, angular, and the like; the fine aggregate size is 0.1 to 5 mm.

[0101] (2) Determine the amount of main gel material, additional component, aggregate, and uniform amount of the main gel material, the main gel material is 120 kg / m based on the weight of the water as ambient ratio. 3 Where the ratio of cement and lime i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com