Electromagnetic guided wave detector and method for sea platform structure defect

A technology for structural defects and offshore platforms, applied to measuring devices, material analysis through electromagnetic means, and material magnetic variables, etc., to achieve high detection efficiency, low detection cost, and low cleaning requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

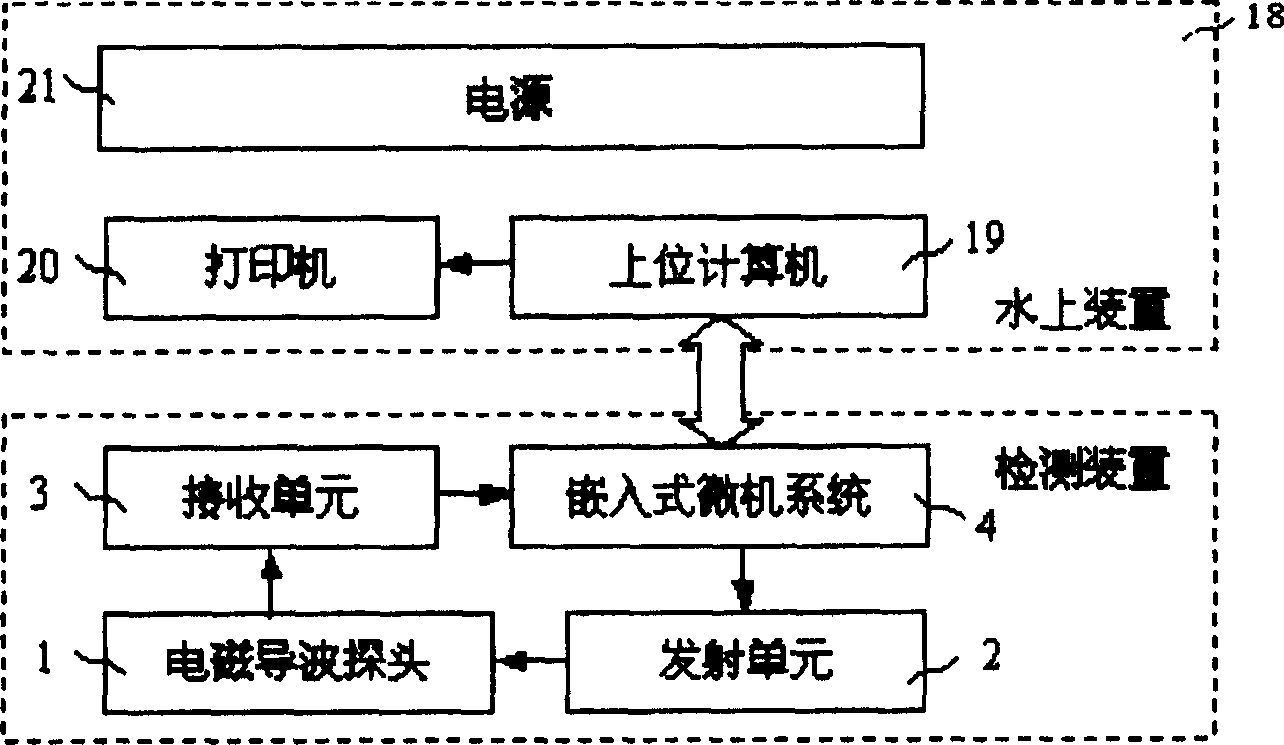

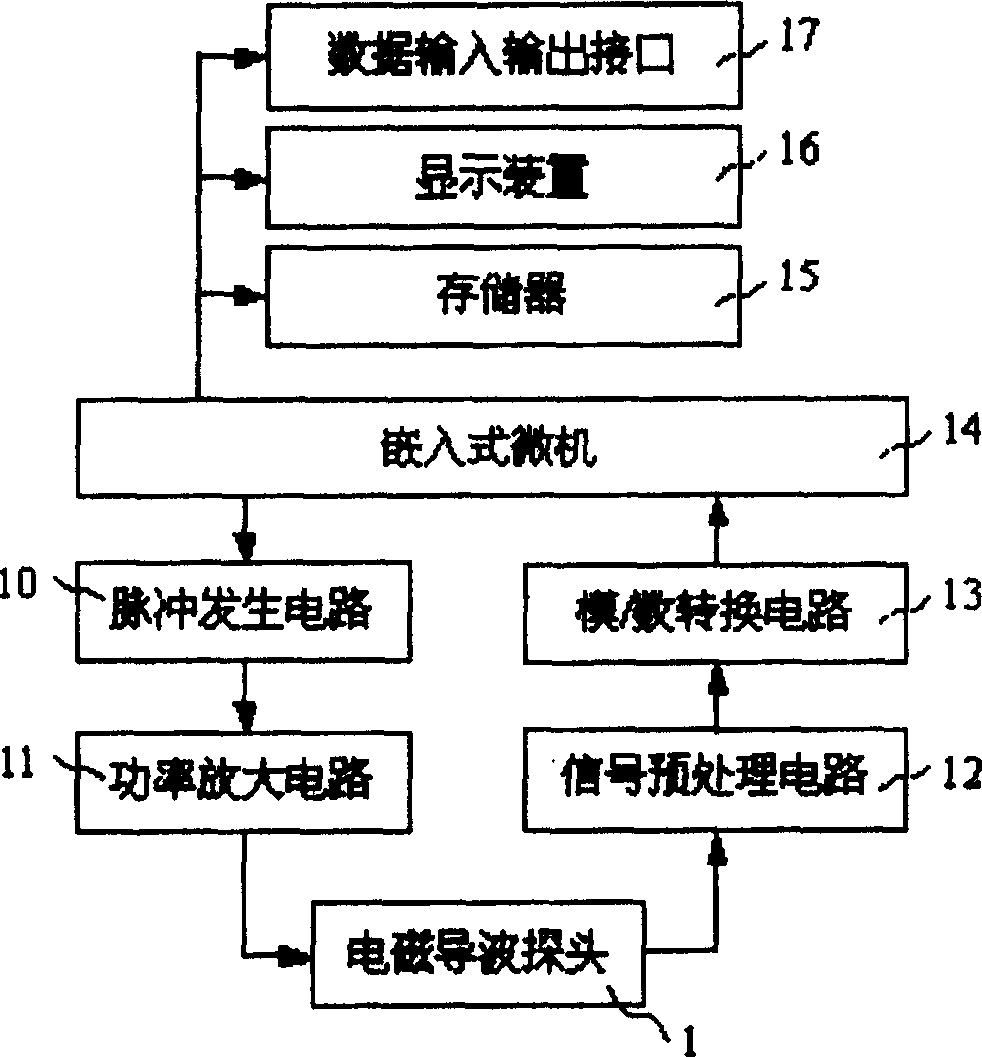

[0032] Such as figure 1 , figure 2As shown, the present invention includes: an electromagnetic guided wave probe 1 , a transmitting unit 2 , a receiving unit 3 and an embedded microcomputer system 4 . The input end of the transmitting unit 2 is connected to the embedded microcomputer system 4, the input end of the electromagnetic guided wave probe 1 is connected to the output end of the transmitting unit 2, and the output end of the electromagnetic guided wave probe 1 is connected to the input end of the receiving unit 3 , the output end of the receiving unit 3 is connected with the embedded microcomputer system 4 .

[0033] The detection device of the present invention can be carried by divers to dive into water for detection, can also be installed on an automatic detection robot for detection, and can also be installed on a manipulator of an intelligent submersible for detection.

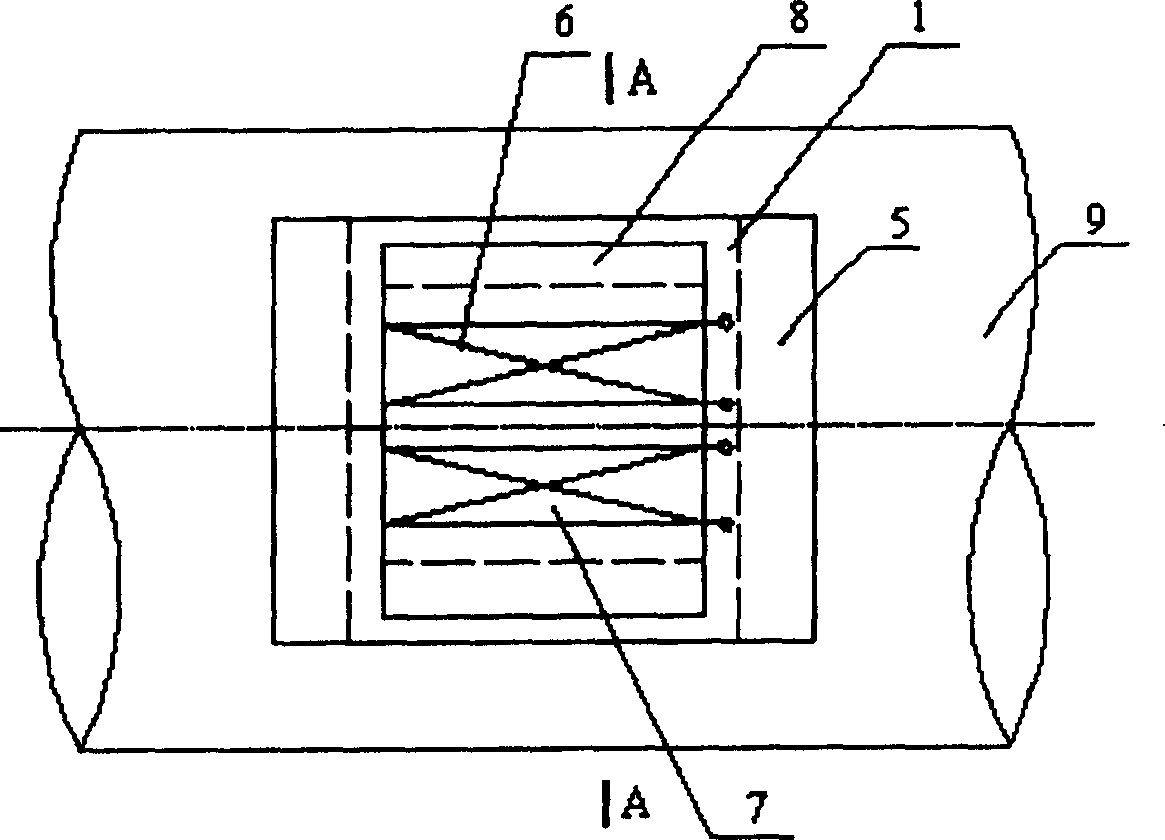

[0034] The electromagnetic guided wave probe 1 adopts a longitudinal electromagnetic guided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com