Replacement Method of Underground Pipeline by Cracking and Plugging Method

A technology for underground pipelines and replacement methods, applied in pipeline laying and maintenance, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of inconvenient repair of urban drainage pipes, achieve low pipeline cleaning requirements, avoid risks, and have stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

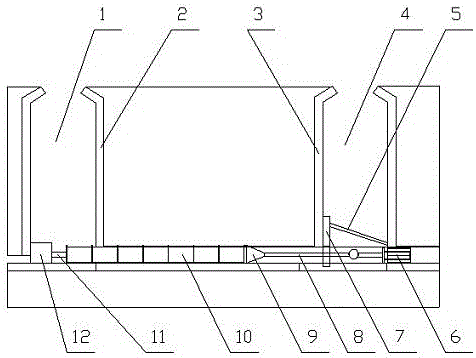

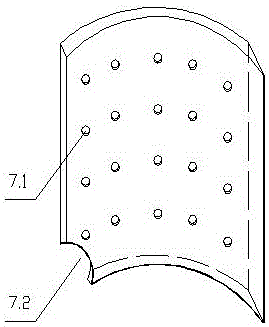

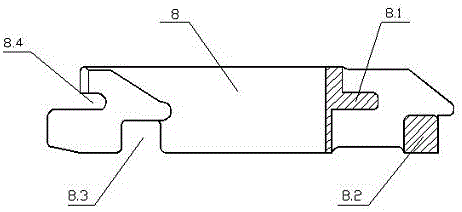

[0023] see Figure 1-6 , the underground pipeline replacement method provided by the present invention is as follows: select two wells of the underground pipeline as construction wells, take one of the construction wells as the replacement starting construction well 1, and use the other construction well as the replacement end construction well 4, with The pipe section between the two construction wells is the construction pipe section. The thrust device 12 is installed in the construction well of the replacement starting point, and the traction device 6 is arranged in the construction well of the replacement end point. The expansion pipe head 9 is pulled by the traction device to make a straight line from the opening of the construction pipe section in the construction well of the replacement starting point. Squeeze forward into the construction pipe section and break the old pipe in the passing section, then stop the traction, place the short pipe 10 for connecting into a new...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com