Treatment device for producing volatile organic pollutants

A volatile organic and pollutant treatment technology, applied in the direction of combustion types, lighting and heating equipment, incinerators, etc., can solve the problems of poor heat storage efficiency of ceramic regenerators, insufficient combustion of harmful gases, and increased external force, etc. Energy consumption, enhancement of combustion sufficiency, effect of complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

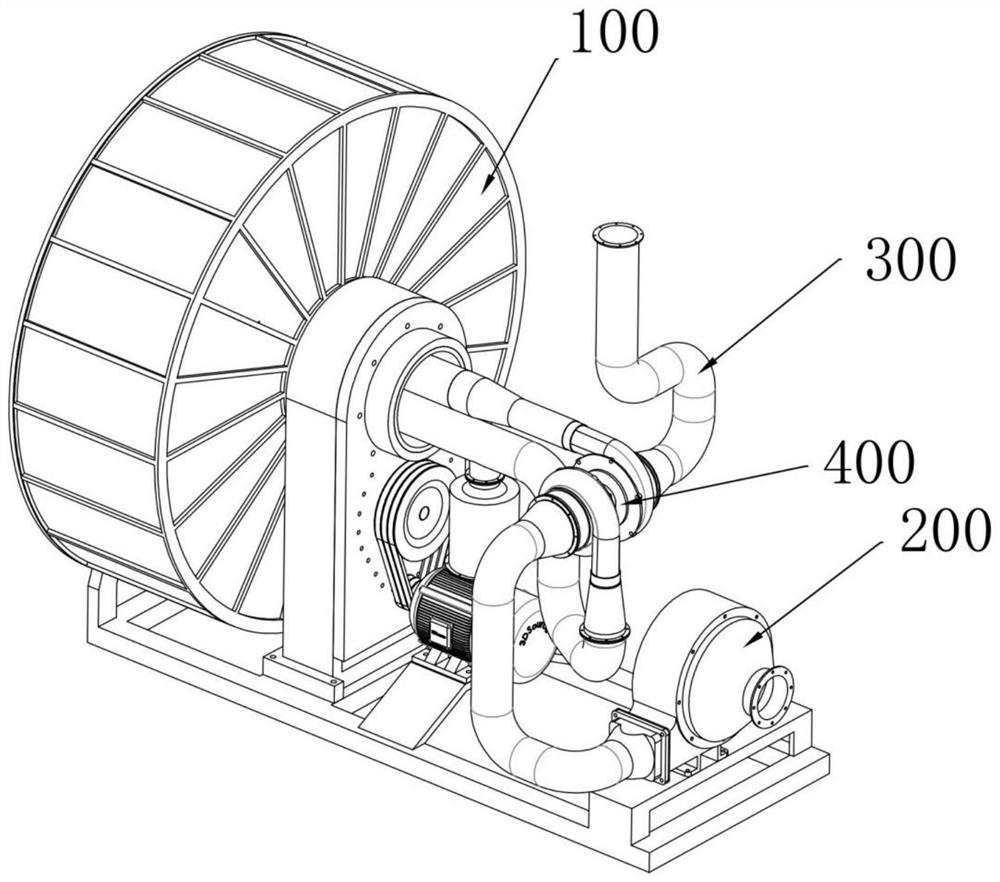

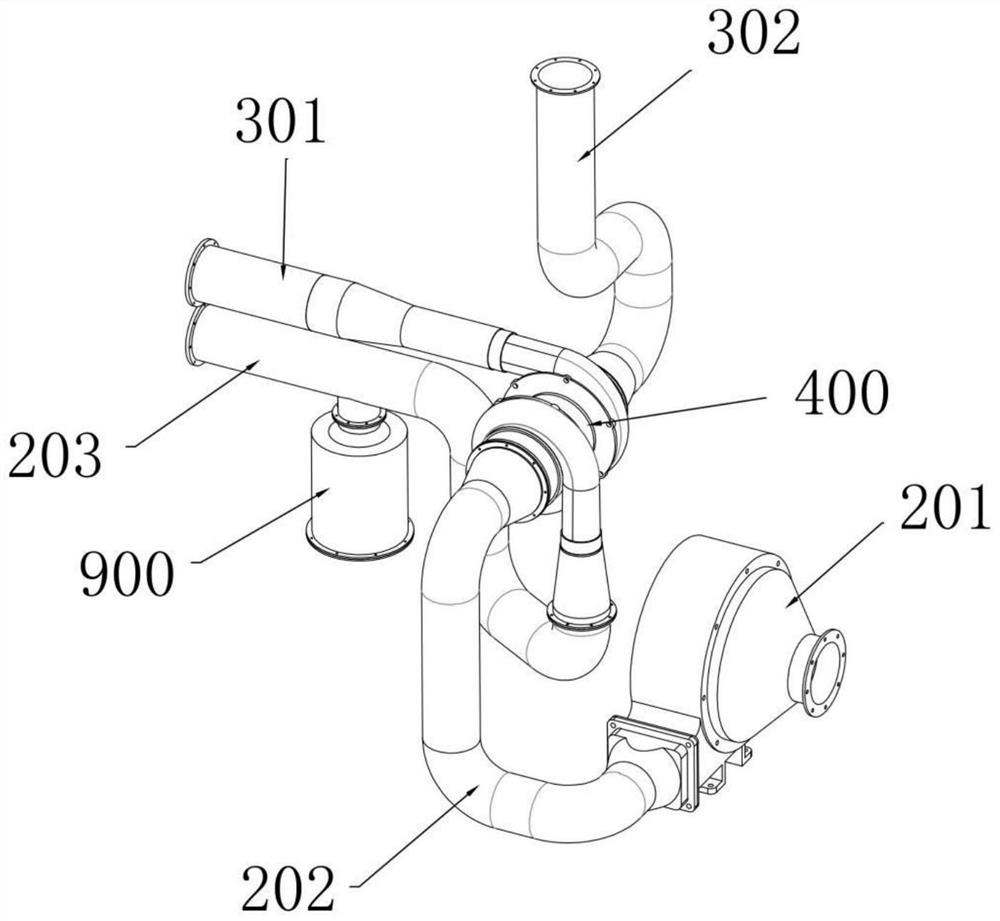

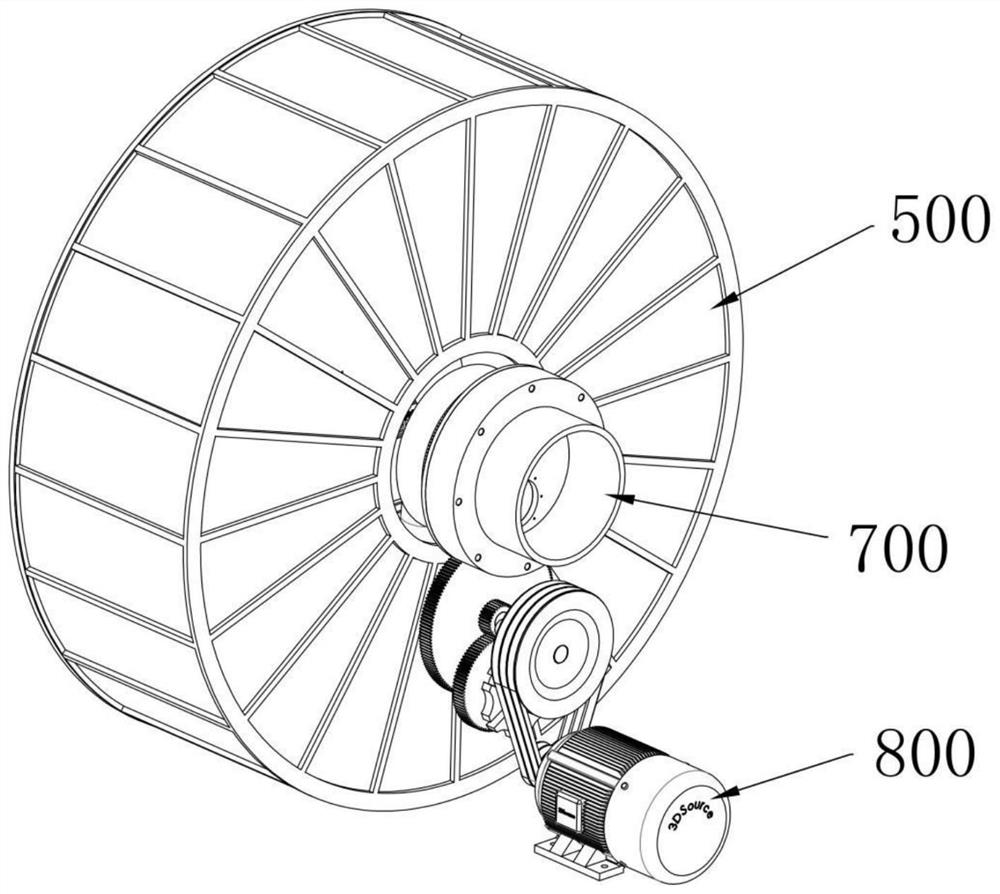

[0063]In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0064] The existing RTO regenerative combustion furnace is mainly composed of a furnace body, a ceramic regenerative body and a combustion system, and is a harmful gas treatment equipment.

[0065] like Figure 14 As shown, the interior of the furnace body is composed of three ceramic medium regenerators and a common combustion chamber, from right to left are the first, second and third regenerators.

[0066] When working, the combustion chamber and the three regenerators work cyclically and in coordination. In the first stage: the harmful gas is sent to the regenerative chamber 1 through the induced draft fan. The heat is released, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com