Large-current power cable and use method thereof

A power cable, high current technology, applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of cable insulation aging, inconvenient use, cable bending, etc., to achieve the effect of good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

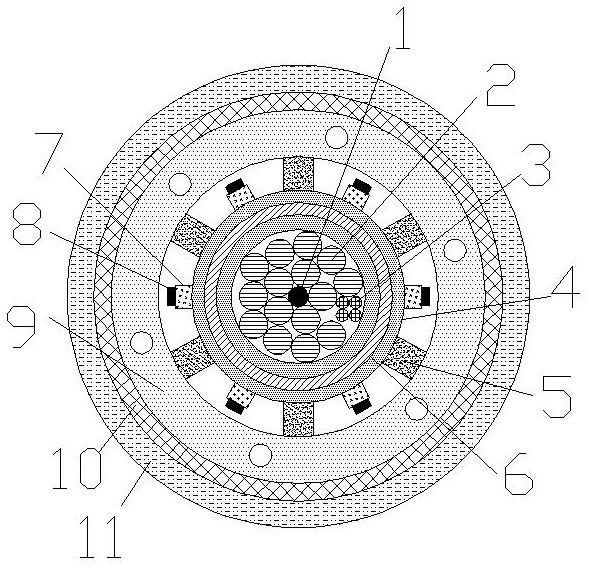

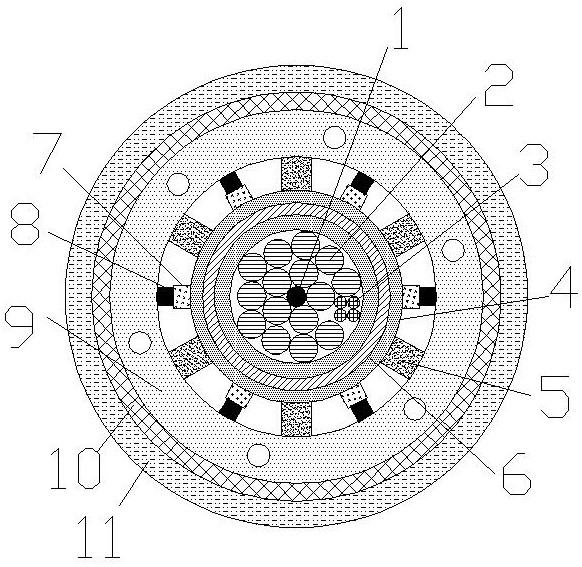

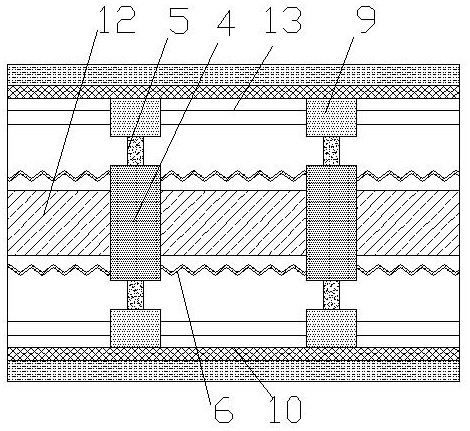

[0036] Figure 1 to Figure 5 In the middle is a high-current power cable, in the figure: 1. Heating resistance line, 2. Conductor, 3. Power line, 4. Heat conduction ring, 5. Insulation column, 6. Telescopic tube, 7. Installation column, 8. Telescopic Column, 9. Cooling ring, 10. High-strength fiber cloth layer, 11. Sheath layer, 12. Cable core, 13. Hose, 14. Power supply, 15. Heating control equipment, 16. Protection resistor, 17. Pressure switch A.

[0037] 2. The outer wall of the cable core is provided with a number of heat-conducting rings, the outer wall of the heat-conducting ring is provided with a number of heat-insulating columns, and the outer wall of the heat-conducting ring is also provided with a number of hollow mounting columns, and the mounting columns are provided with telescopic columns, A thermal expansion material is arranged between the telescopic column and the installation column;

[0038] There are installation grooves on both sides of the heat conduc...

example 2

[0048] figure 1 , figure 2 , Figure 5 and Image 6 In the middle is a high-current power cable, in the figure: 1. Heating resistance line, 2. Conductor, 3. Power line, 4. Heat conduction ring, 5. Insulation column, 6. Telescopic tube, 7. Installation column, 8. Telescopic Column, 9. Cooling ring, 10. High-strength fiber cloth layer, 11. Sheath layer, 12. Cable core, 13. Hose, 14. Power supply, 15. Heating control equipment, 16. Protection resistor, 17. Pressure switch A, 18. Casing.

[0049] 3. The cable core jacket is provided with a number of heat-conducting rings, the outer wall of the heat-conducting ring is provided with a number of heat-insulating columns, the outer wall of the heat-conducting ring is also provided with a number of hollow mounting columns, and a telescopic column is arranged in the mounting column, A thermal expansion material is arranged between the telescopic column and the installation column;

[0050] There are installation grooves on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com