Photovoltaic array fault defect diagnosis system and method

A photovoltaic array, fault defect technology, applied in the monitoring of photovoltaic systems, photovoltaic modules, instruments, etc., can solve problems such as battery and panel burnout, battery cracking, power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for diagnosing faults and defects of a photovoltaic array, comprising the following steps:

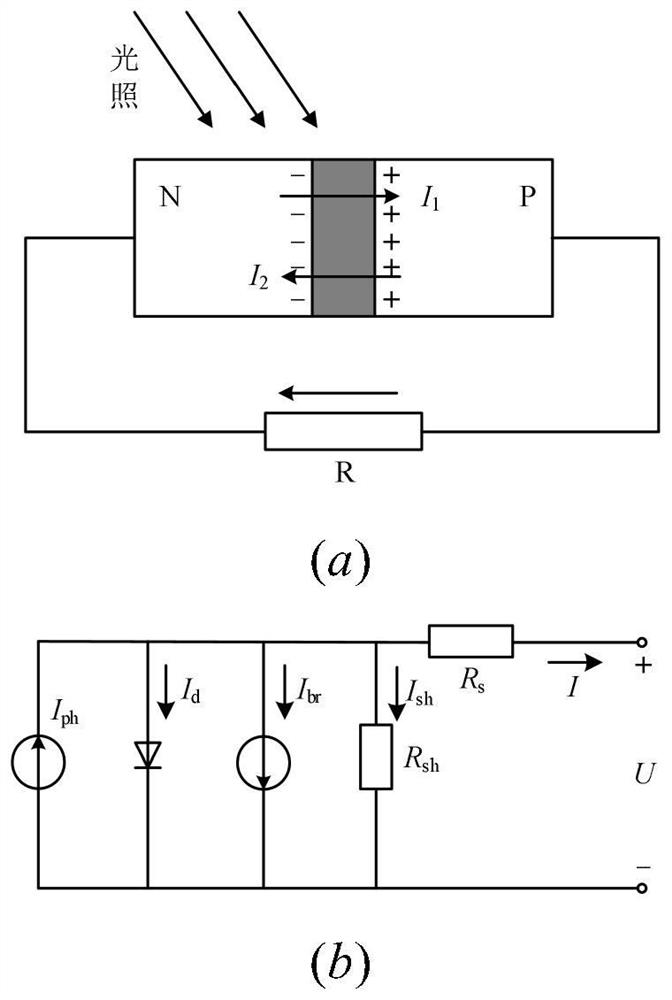

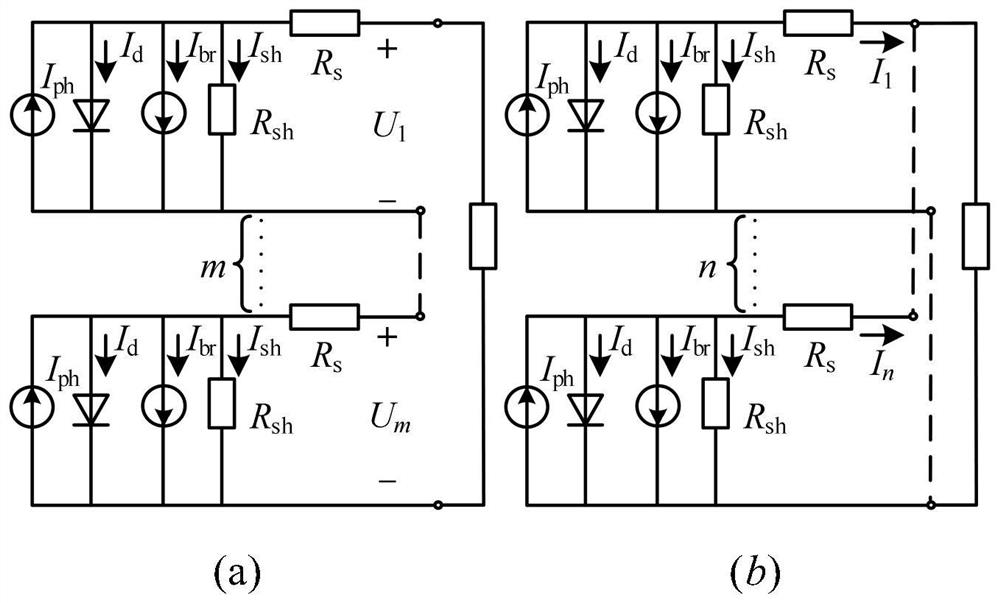

[0054] Step 1: Collect the voltage and current values of each photovoltaic cell string through the voltage and current sensors. The output current and voltage of the photovoltaic cell string formed by m photovoltaic cell modules in series are:

[0055] I out =I i (1)

[0056]

[0057] In formulas (1) and (2), I out is the total output current of the photovoltaic cell string, U out is the total output voltage of the photovoltaic cell string, m is the number of photovoltaic cell rows, I i is the current of the photovoltaic cell module in the i-th row, U i is the voltage of the photovoltaic cell module in the i-th row, i=1, 2, . . . m.

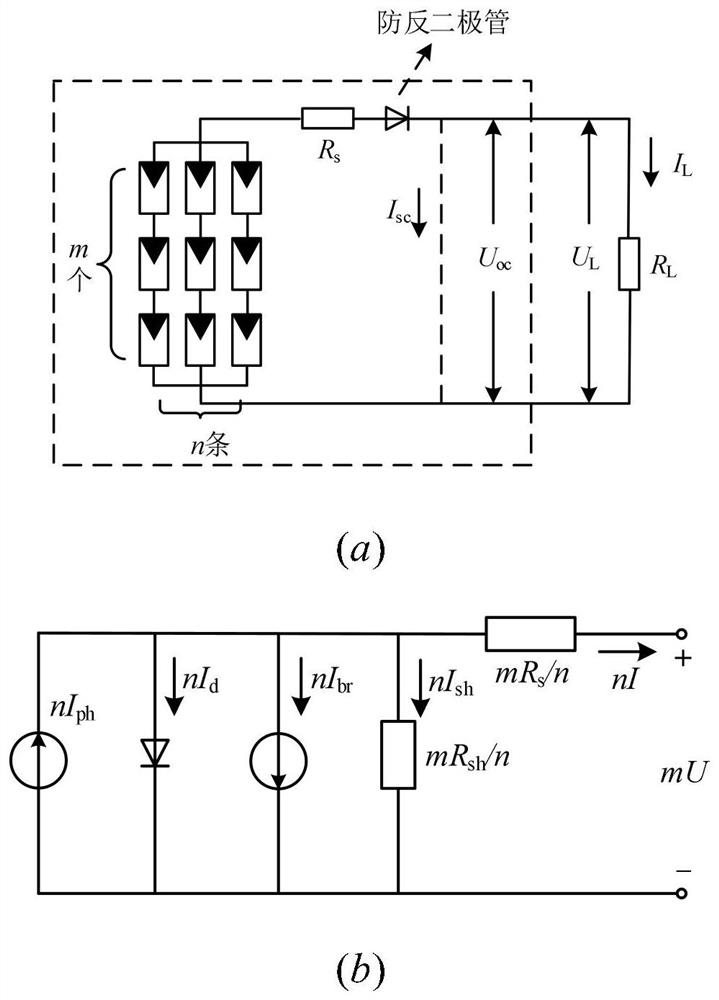

[0058] The output current and voltage of the photovoltaic array formed by n columns of photovoltaic cells in series and parallel are:

[0059]

[0060] U out =U j (4)

[0061] In formulas (3) and (4), I out is the total ...

Embodiment 2

[0121] A photovoltaic array fault defect diagnosis system, which can implement the photovoltaic array fault defect diagnosis method in Embodiment 1, including:

[0122] Acquisition module: used to collect the voltage and current values of each photovoltaic cell string in the photovoltaic array;

[0123] Positioning module: used to compare the collected voltage values and find the battery string with the smallest voltage value and its current and voltage values;

[0124] Primary judgment module: used to calculate the difference between the voltage value of the battery string with the smallest voltage value and the voltage value under normal operation, and determine whether the difference exceeds the normal deviation;

[0125] Recollection module: used to recollect the voltage and current values of each photovoltaic cell string in the photovoltaic array to continue monitoring in response to the difference value not exceeding the normal deviation;

[0126] Secondary judgme...

Embodiment 3

[0130] The embodiment of the present invention also provides a photovoltaic array fault defect diagnosis device, which can implement the photovoltaic array fault defect diagnosis method in the first embodiment, including a processor and a storage medium;

[0131] the storage medium is used for storing instructions;

[0132] The processor is configured to operate in accordance with the instructions to perform the steps of the following methods:

[0133] Collect the voltage and current values of each photovoltaic cell string in the photovoltaic array;

[0134] Compare the collected voltage values to find the battery string with the smallest voltage value and its current and voltage values;

[0135] Calculate the difference between the voltage value of the battery string with the smallest voltage value and the voltage value under normal operation, and judge whether the difference exceeds the normal deviation;

[0136] In response to the difference value not exceeding the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com