Crushing, mixing and granulating equipment for manufacturing kitchen waste bio-organic fertilizer

A bio-organic fertilizer and kitchen waste technology, applied in the direction of raw material extrusion granulation, climate change adaptation, etc., can solve the problems of raw material waste, raw material accumulation, high energy consumption, etc., and achieve ingenious structural design, compact structure design, and granular consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

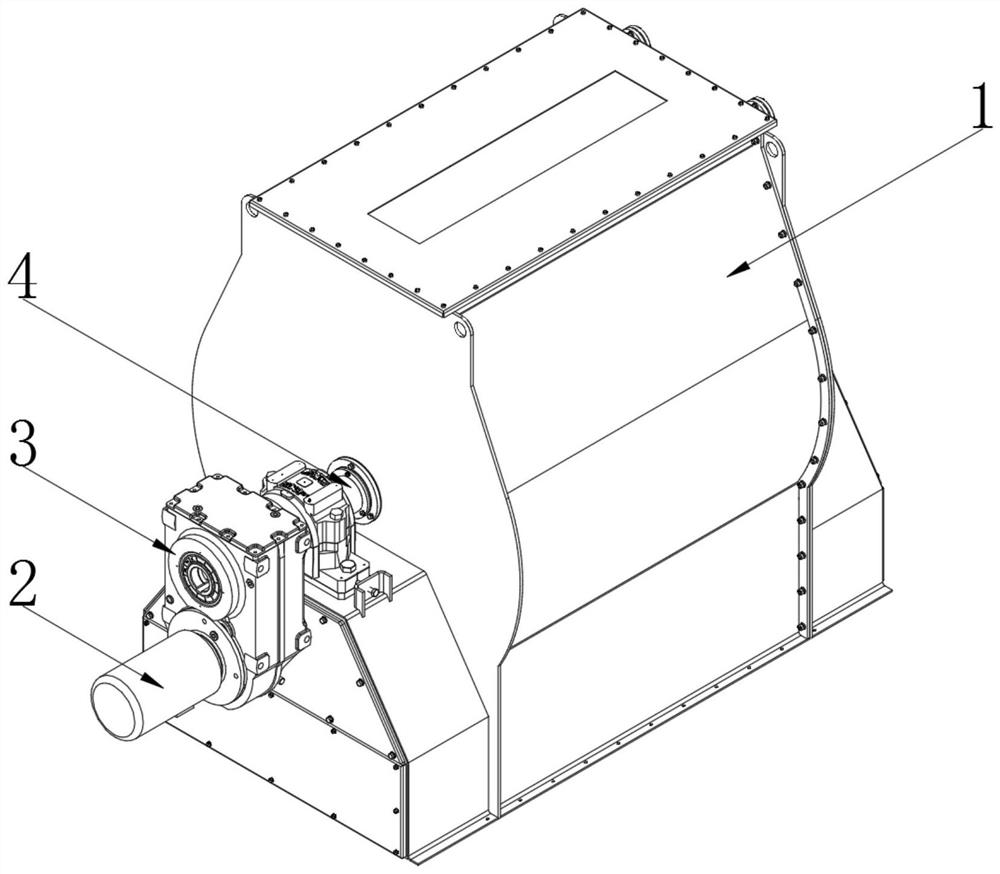

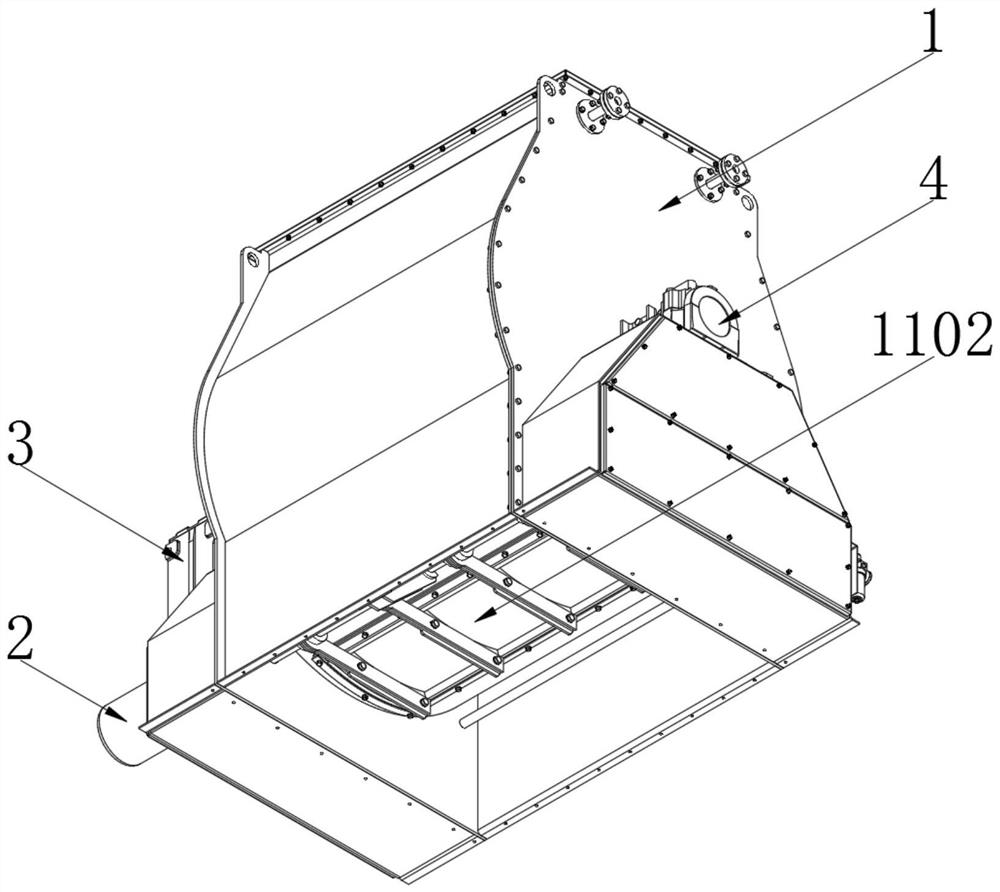

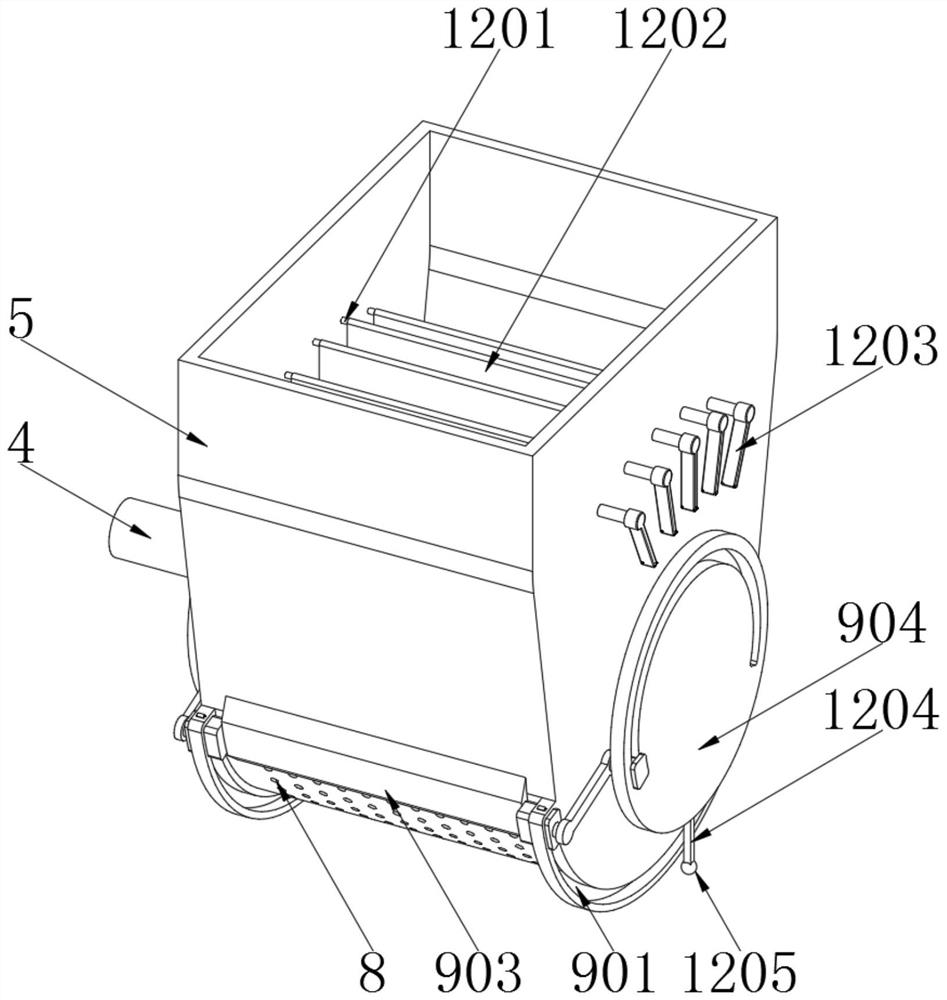

[0047] Example: as Figure 1 to Figure 12 As shown, the present invention provides the following technical solutions, a pulverizing, mixing and granulating equipment for the manufacture of kitchen waste bio-organic fertilizer, the granulating equipment comprises an outer casing 1 and an inner casing 5, and one end of the outer casing 1 is provided with a servo motor 2, The output shaft of the servo motor 2 is meshed with the drive shaft 4 through the gear box 3 , the outer casing 1 is provided with an inner casing 5 , and the bio-organic fertilizer raw material is granulated inside the inner casing 5 , and the drive shaft 4 penetrates the outer casing 1 . It is arranged with the inner casing 5, and several granulating rollers 7 are rotated and installed on the drive shaft 4 through the fixing frame 6. 5. The bottom is arc-shaped, and the bottom of the inner shell 5 is provided with a number of forming holes 8. The forming holes 8 are used to shape the bio-organic fertilizer ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com