New energy automobile part machining device and using method

A technology for new energy vehicles and processing devices, which is applied to spray devices, liquid spray devices, etc., can solve the problems of inability to ensure the uniformity of spray paint, the clogging of the paint layer inside the car, and the low adhesion of the paint layer, so as to save painting materials and labor. The effect of consumption, simple structure and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

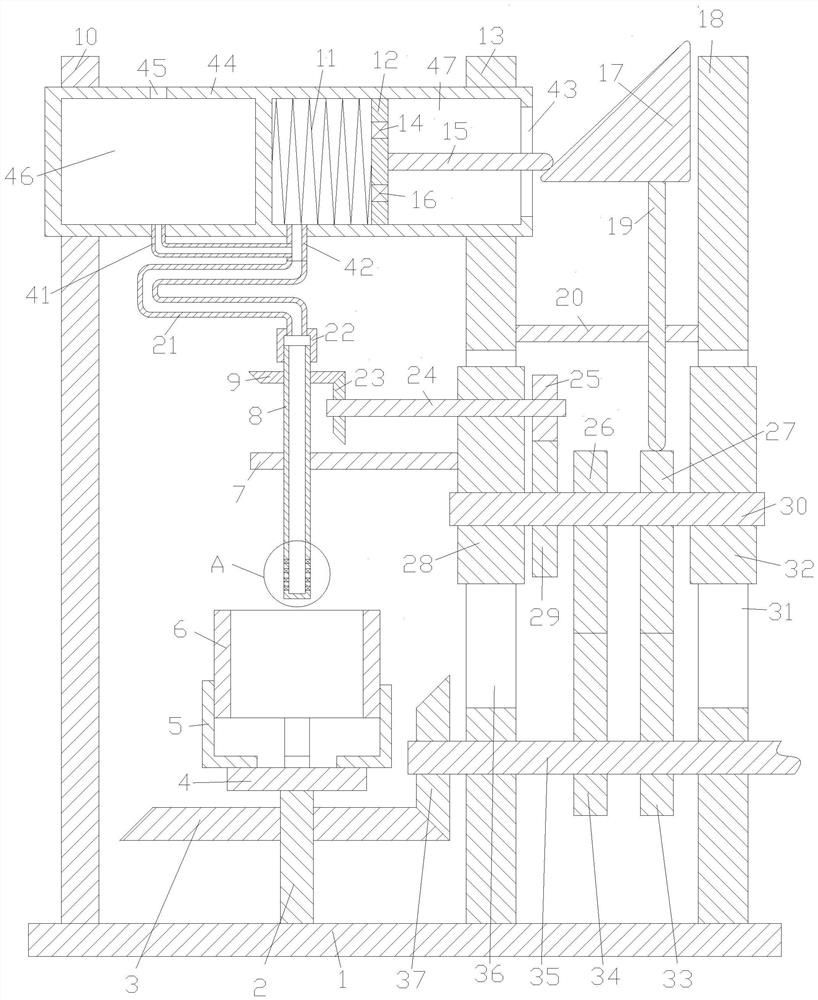

[0021] The present invention will be further described below in conjunction with the accompanying drawings:

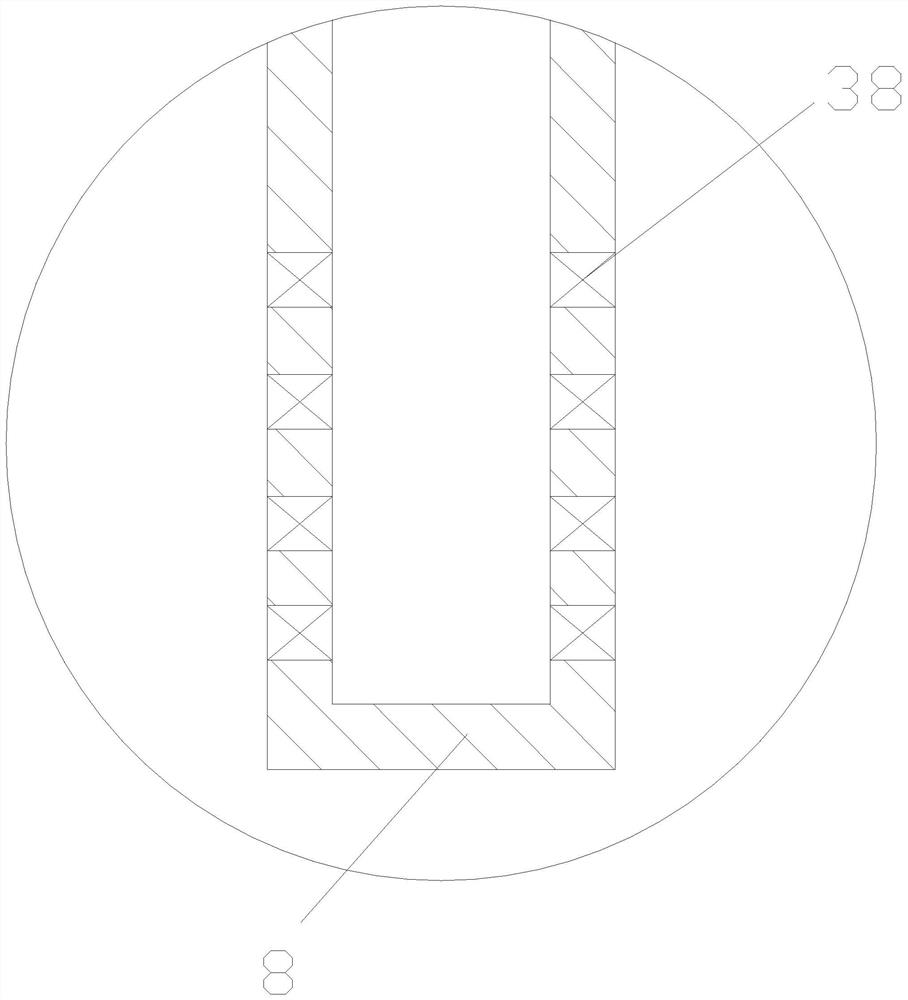

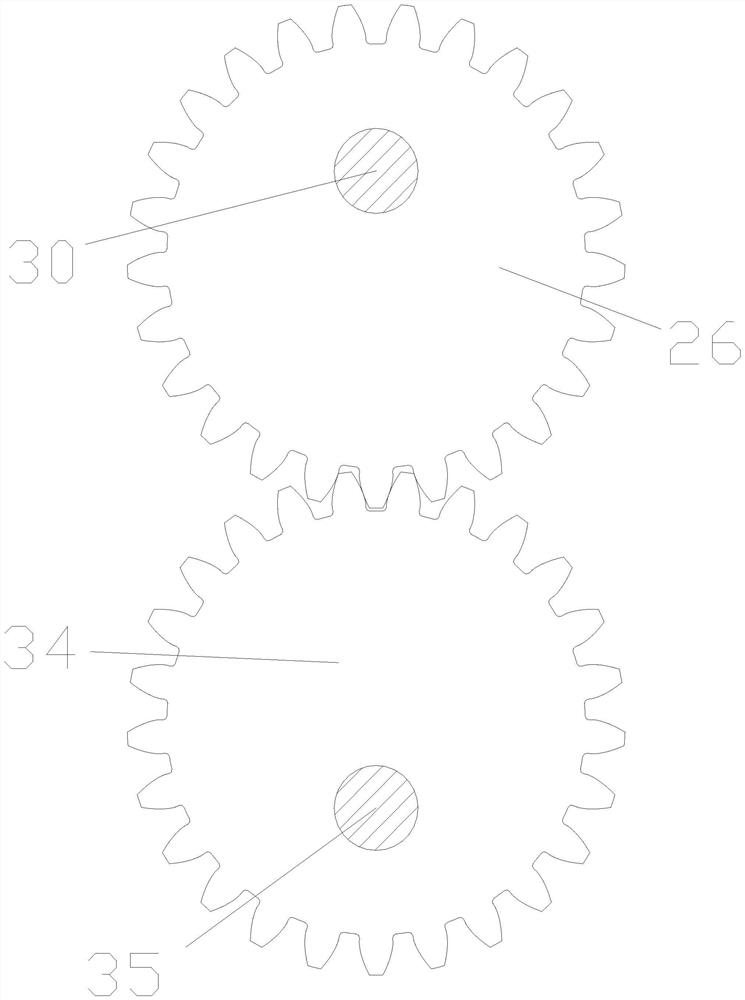

[0022] Refer to the attached Figures 1~5: In this embodiment, the new energy vehicle parts processing device includes a bottom plate 1, and the bottom plate 1 is fixedly installed with a first support plate 10, a second support plate 13, and a third support plate 18 in sequence from left to right. The second support plate 13 is provided with a first chute 36 , the third support plate 18 is provided with a second chute 31 corresponding to the first chute 36 , and the inner wall of the first chute 36 is slidably connected with a second chute 31 . A sliding block 28, a second sliding block 32 is slidably connected to the inner wall of the second sliding groove 31, a first rotating shaft 35 is rotatably connected to the second supporting plate 13 and the third supporting plate 18, A first bevel gear 37 located on the left side of the second support plate 13 is fixedly mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com