Cotton swab grinding and polishing equipment for cotton swab production

A technology of using cotton swabs and cotton swabs is applied in the field of cotton swab grinding and polishing equipment used for cotton swab production, to save manpower and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

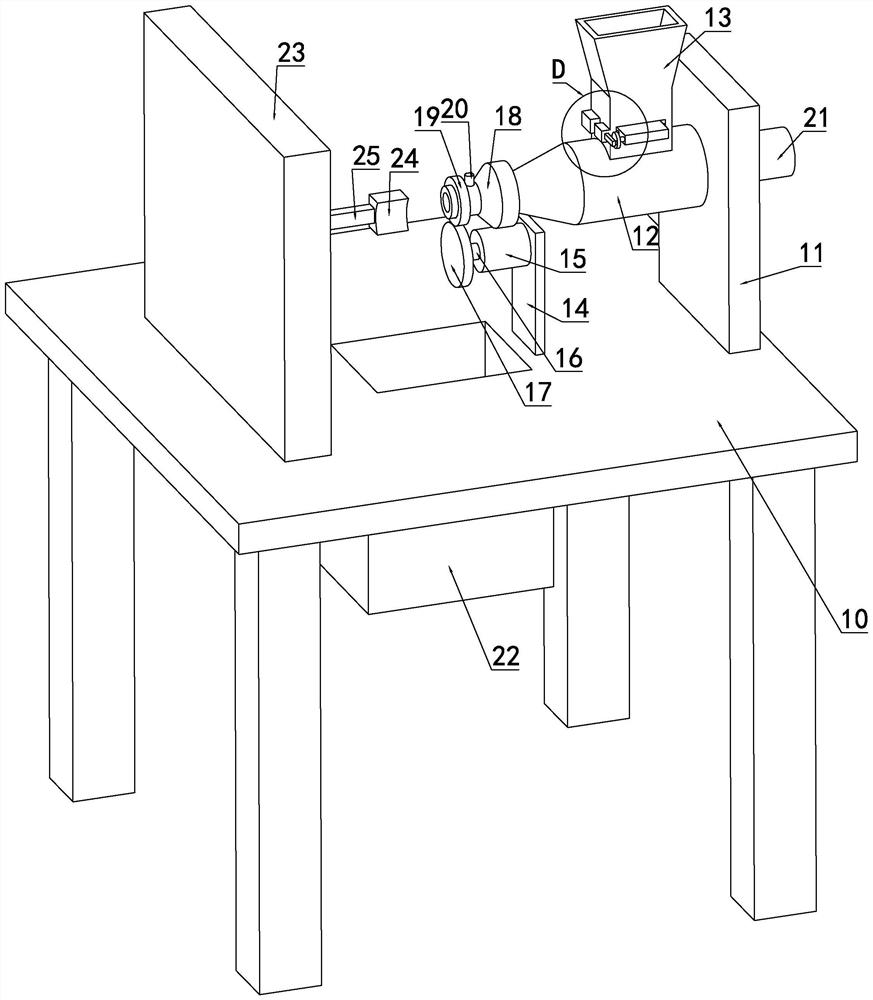

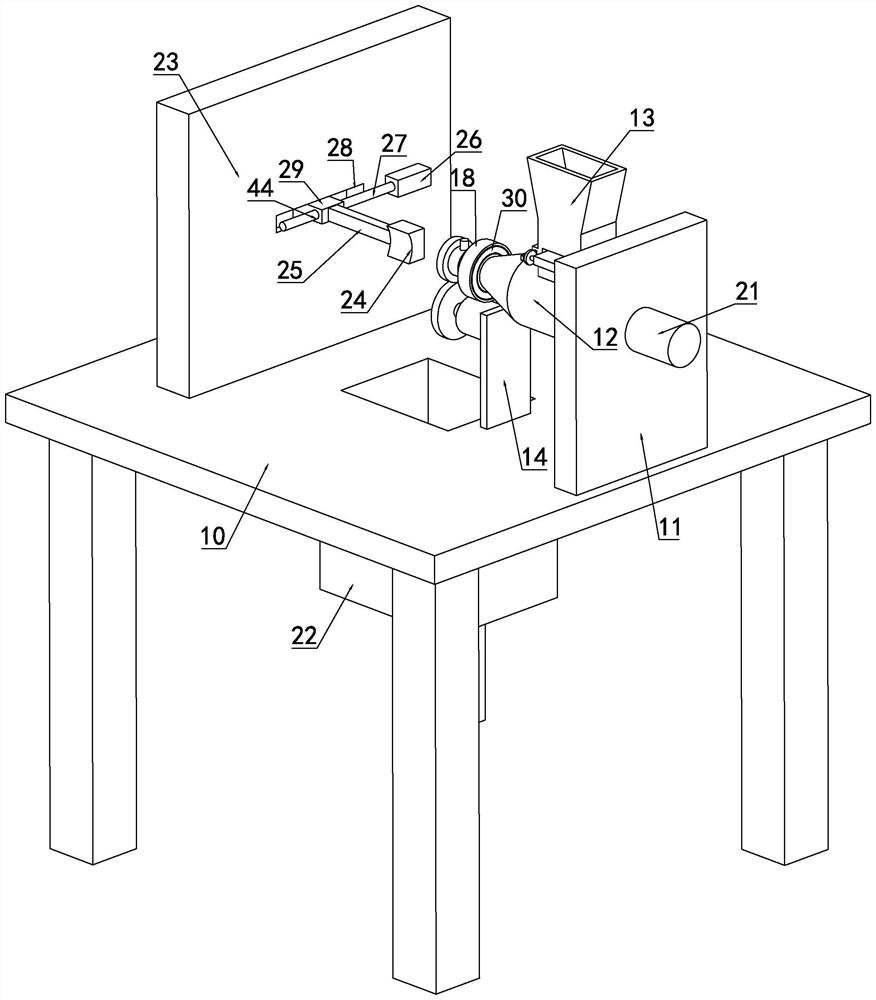

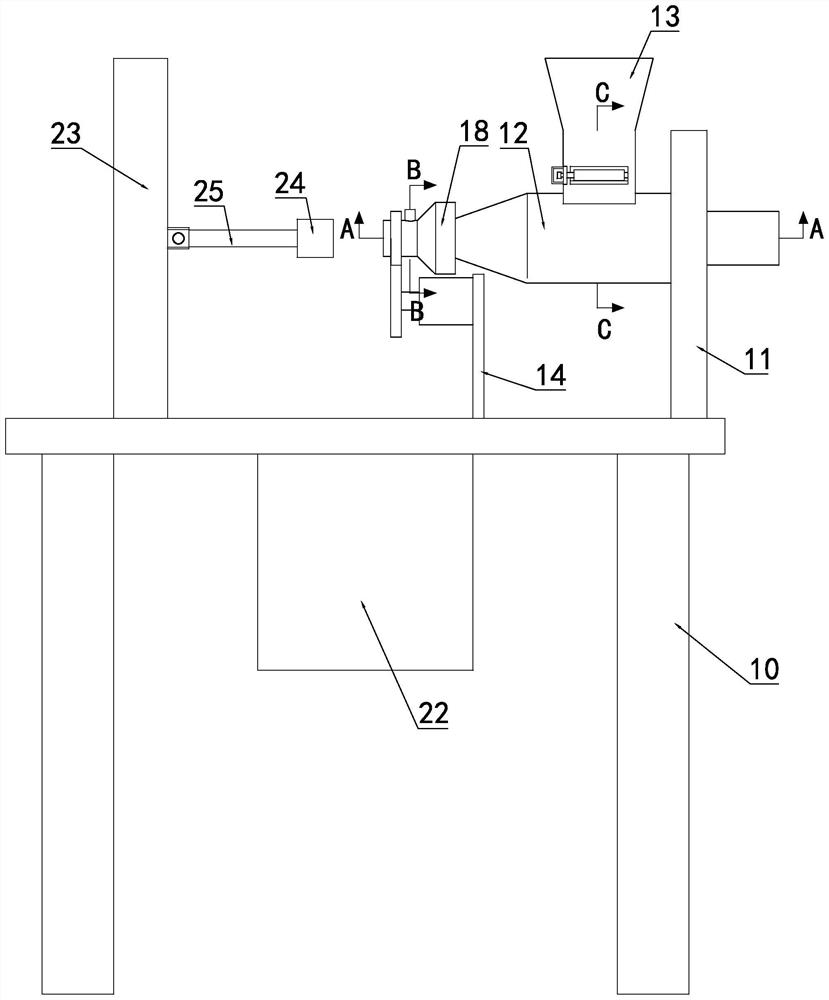

[0032] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0033] like figure 1 , Figure 4 , Image 6 and Figure 7As shown, a cotton swab grinding and polishing equipment for cotton swab production includes a base 10, a first fixing plate 11 is fixed on the right end of the upper side of the base 10, and a push box 12 is fixed on the left side of the first fixing plate 11. There is a push cavity 34, a feed port 13 is fixed on the upper side of the push box 12, the feed port 13 communicates with the push cavity 34, a groove 43 is provided at the front end of the feed port 13, and a baffle 35 is rotated in the groove 43. , a rotating shaft 37 is fixed on the left side of the baffle 35, an eccentric wheel 38 is fixed on the left side of the rotating shaft 37, a rotating shaft 39 is fixed on the left f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com