Method for manufacturing one-step formed water-based adhesive kraft paper adhesive tape

A production method and technology of kraft paper, which are applied in the directions of adhesives, film/sheet-like adhesives, and devices for coating liquid on the surface, etc., can solve the problems of many steps, low processing efficiency, poor environmental protection, etc., and achieve high fastness. , the effect of overcoming the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

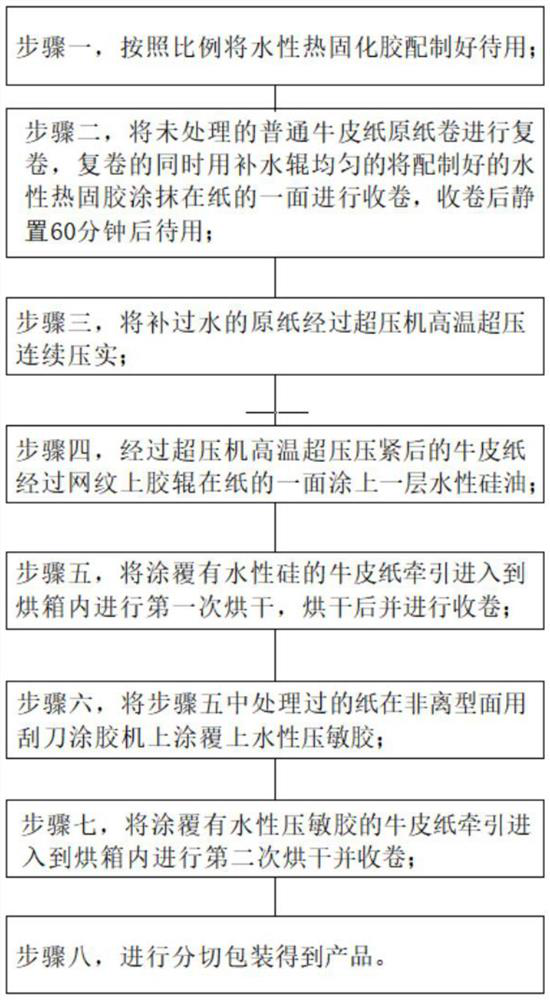

Image

Examples

Embodiment 1

[0026] The present specific embodiment discloses a method for making a one-shot water-based adhesive kraft paper tape, which completes the one-shot production of the water-based glue kraft paper tape through the following steps:

[0027] Step 1, dilute the water-based thermosetting adhesive according to the proportion and prepare it for use; preferably, when preparing, the content of the water-based thermosetting adhesive is 15%, which is feasible. Before use, it can be prepared with a stirring device and pumped through a metering pump. to the replenishment roller for use. Feasible, food-grade heat-curing adhesives use low-plasticizing heat-curing acrylic adhesives.

[0028] Step 2, rewind the untreated ordinary kraft paper base paper roll, and evenly apply the prepared water-based thermosetting adhesive on one side of the paper with a water replenishing roller while rewinding, and let it stand for 60 minutes after rewinding. use;

[0029] In step 3, the base paper that has ...

Embodiment 2

[0037] The present specific embodiment discloses a method for making a one-shot water-based adhesive kraft paper tape, which completes the one-shot production of the water-based glue kraft paper tape through the following steps:

[0038] Step 1, dilute the water-based thermosetting adhesive according to the proportion and prepare it for use; preferably, when preparing, the content of the water-based thermosetting adhesive is 15%, which is feasible. Before use, it can be prepared with a stirring device and pumped through a metering pump. to the replenishment roller for use. Feasible, food-grade heat-curing adhesives use low-plasticizing heat-curing acrylic adhesives.

[0039] Step 2, rewind the untreated ordinary kraft paper base paper roll, and evenly apply the prepared water-based thermosetting adhesive on one side of the paper with a water replenishing roller while rewinding, and let it stand for 60 minutes after rewinding. use;

[0040] In step 3, the base paper that has ...

Embodiment 3

[0047] The present specific embodiment discloses a method for making a one-shot water-based adhesive kraft paper tape, which completes the one-shot production of the water-based glue kraft paper tape through the following steps:

[0048] Step 1, dilute the water-based thermosetting adhesive according to the proportion and prepare it for use; preferably, when preparing, the content of the water-based thermosetting adhesive is 15%, which is feasible. Before use, it can be prepared with a stirring device and pumped through a metering pump. to the replenishment roller for use. Feasible, food-grade heat-curing adhesives use low-plasticizing heat-curing acrylic adhesives.

[0049] Step 2, rewind the untreated ordinary kraft paper base paper roll, and evenly apply the prepared water-based thermosetting adhesive on one side of the paper with a water replenishing roller while rewinding, and let it stand for 60 minutes after rewinding. use;

[0050]In step 3, the base paper that has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com