Brake handle protective cover and manufacturing method thereof

A technology of protective cover and handle, which is applied in the direction of safety devices, machines/engines, mechanical equipment, etc., can solve the problems that the exposure of the brake handle does not meet the requirements of the specifications, and it is easy to cause accidental production accidents, so as to improve the demonstration and beautiful appearance , the effect of preventing accidental touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

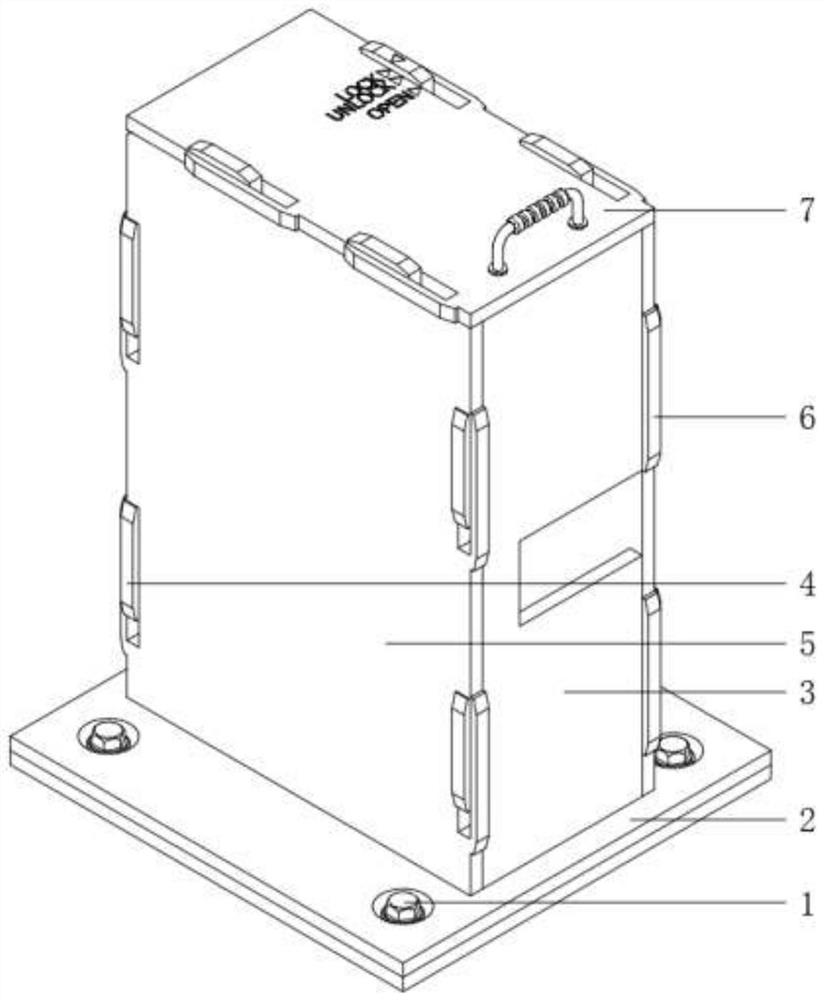

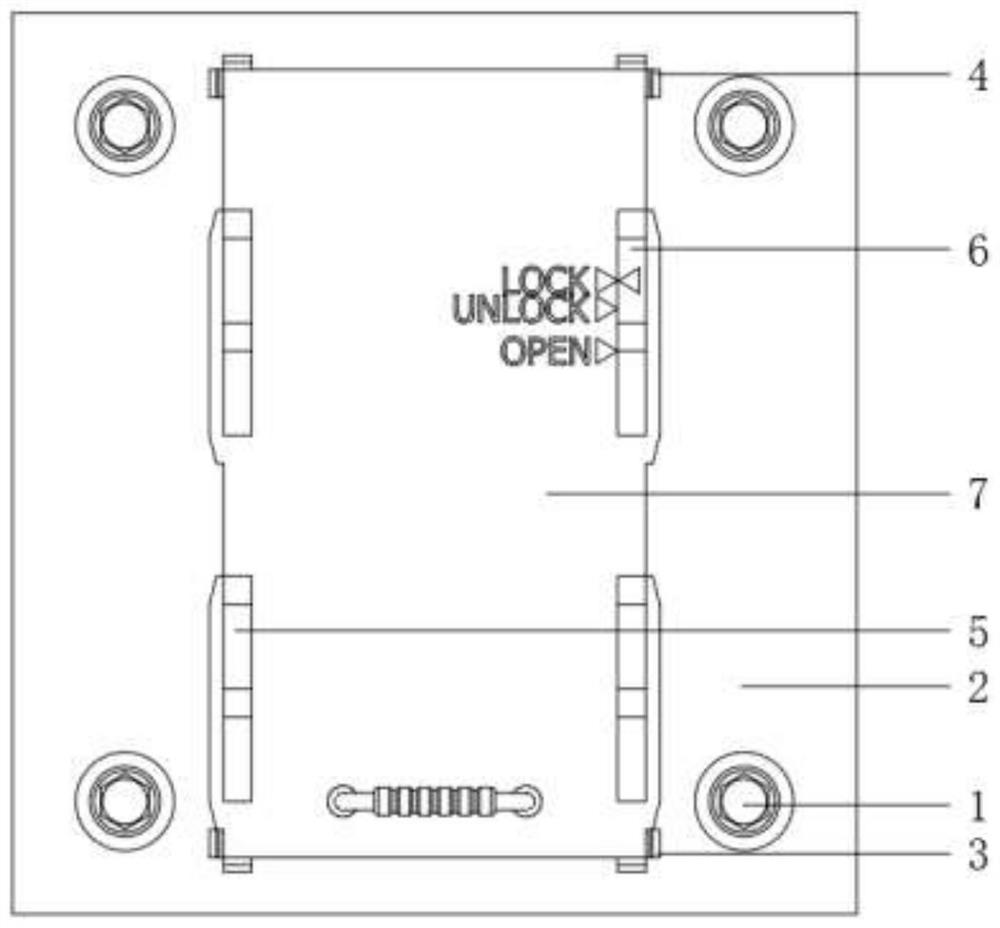

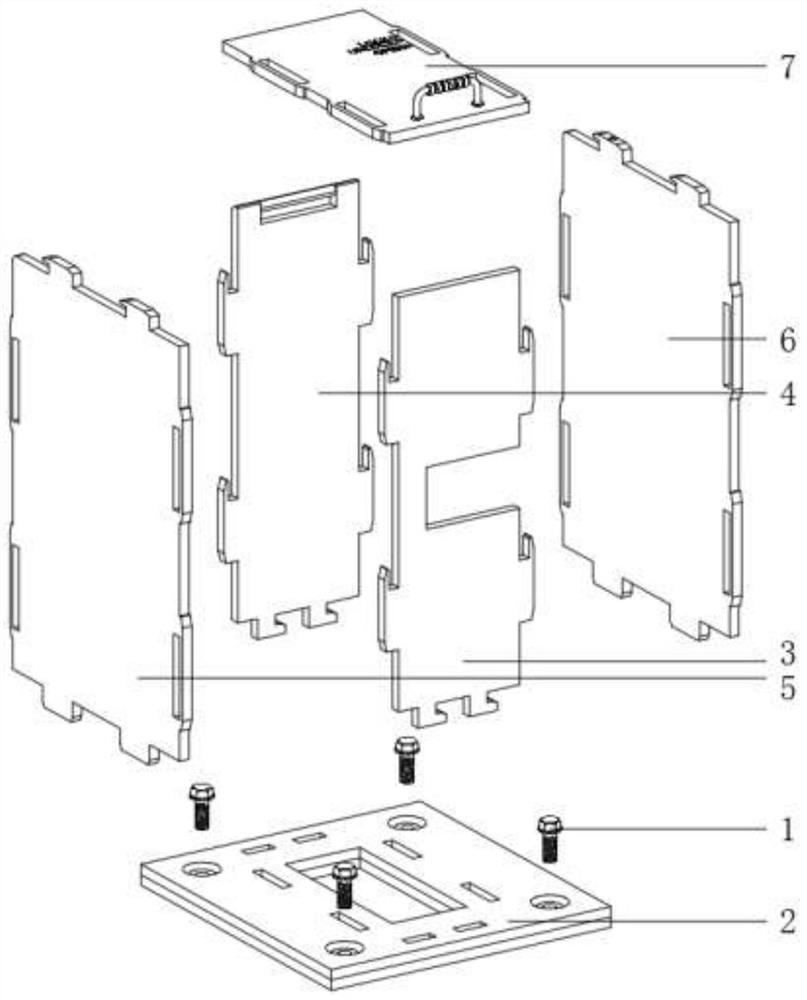

[0040] Embodiment, a kind of brake handle protective cover and its making method, comprise the following steps:

[0041] S1. Cutting sheet: according to drawings (such as Figure 10 ) Cut out the upper bottom plate 21, the lower bottom plate 22, the front fender 3, the handle stabilization block 34, the rear fender 4, the left fender 5, the right fender 6, the protective flip cover 7 and a plurality of the plate-shaped hooks 731;

[0042] S2. Plate engraving: reaming the plurality of bolt holes 221 on the upper bottom plate 21 through engraving; rounding the turning shaft 41 at the upper end of the rear fender 4 through engraving; on the right fender The alignment mark 61 is engraved on the top surface of one of the cover hooks 53 on

[0043] S3. Complete parts: use high-concentration 6283 PVC glue to adhere the upper bottom plate 21 and the lower bottom plate 22 to each other to form the protective base 2; use high-concentration 6283 PVC glue to stick the handle stabilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com