Filter capacitor for converter station

A filter capacitor, filter capacitor technology, applied in the direction of feed-through capacitors, anti-noise capacitors, fixed capacitor terminals, etc., can solve the problems of reducing service life, economic losses, damage to the structure of the capacitor body, etc., and achieve the effect of simple setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

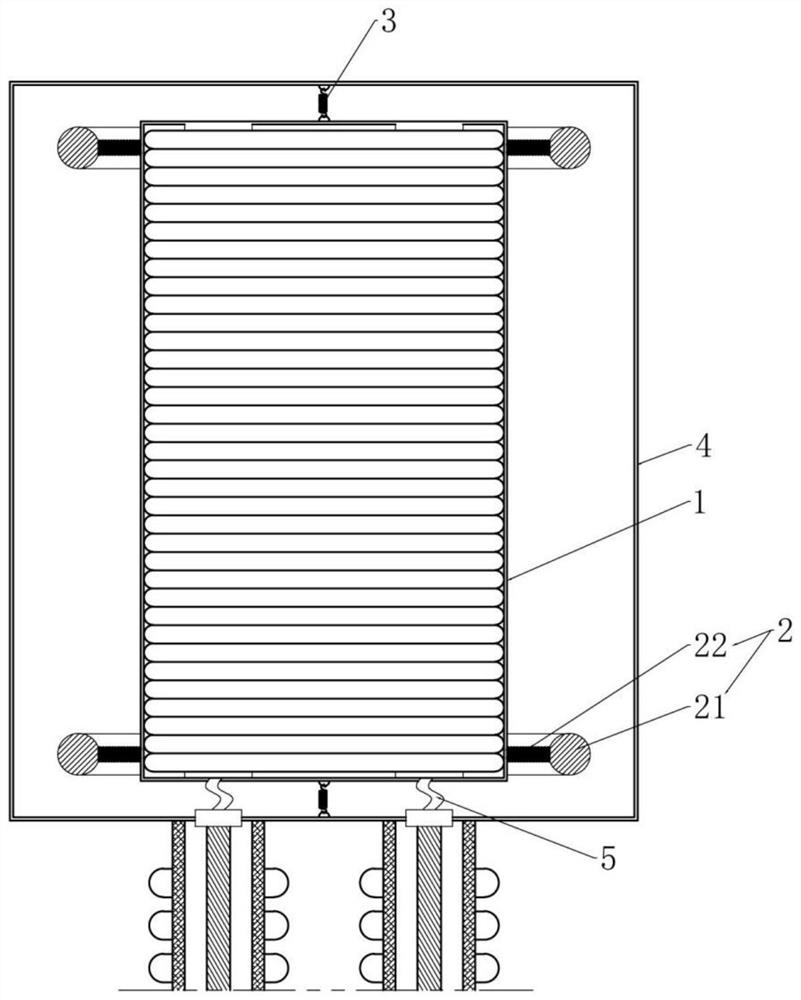

[0020] Embodiment 1: A filter capacitor for a converter station, see figure 1 , including a vacuum shell 4, a filter capacitor module 1 and a vibration damping device.

[0021] The airtightness of the vacuum housing 4 satisfies that the smaller the degree of vacuum, the better. An extraction electrode is provided on the vacuum shell 4 . In this embodiment, the vacuum casing 4 is an insulating casing. The insulating shell has poor weather resistance. In other embodiments, the vacuum shell 4 can also be a metal shell, and the metal shell is provided with a lead-out electrode opening, and the lead-out electrode is arranged at the lead-out electrode opening and is insulated from the metal shell through an insulating member.

[0022] The filter capacitor module 1 is arranged in the vacuum shell 4 , and the terminals of the filter capacitor module 1 are electrically connected to the lead-out electrodes through flexible wires 5 respectively. The filter capacitor module 1 is non-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com