Air extruder, traction battery, manufacturing method and motor vehicle

A technology for traction batteries and extruders, applied in battery pack parts, secondary battery gas removal, secondary battery repair/maintenance, etc., can solve problems such as high structural space requirements, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

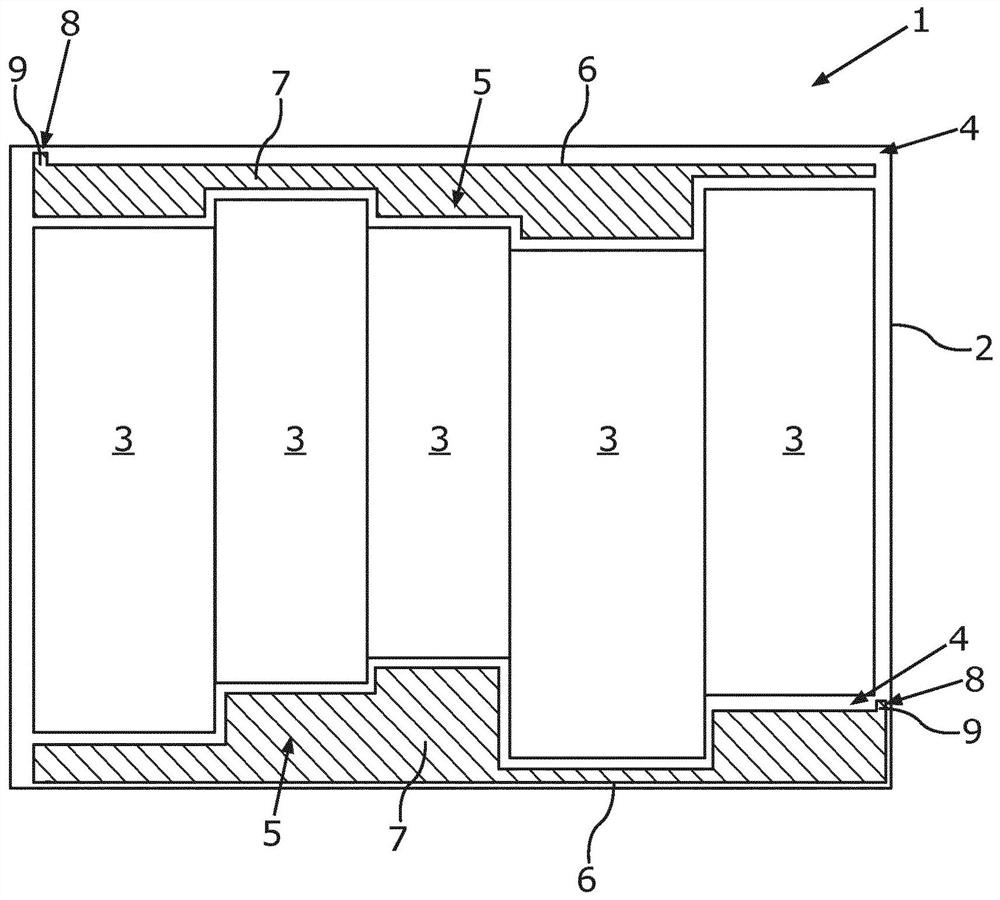

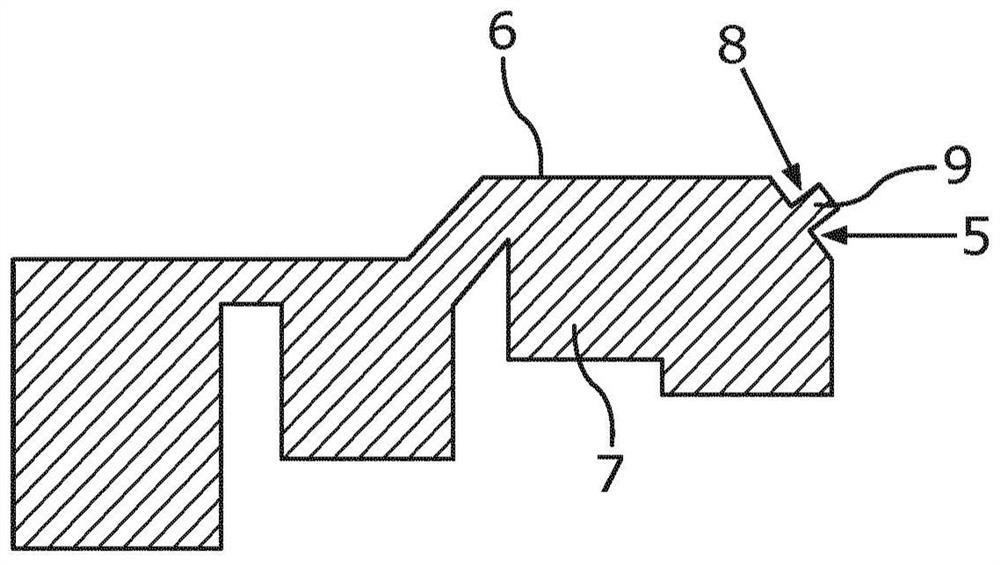

[0022] In the figures, identical and functionally identical elements are provided with the same reference numerals.

[0023] figure 1 A traction battery 1 for an electrically drivable motor vehicle is shown. The traction battery 1 has a battery housing 2 in which a plurality of components 3 , such as battery modules, are arranged. In order to fill the free volume 4 (which is defined by the free spaces between the parts 3 and between the parts 3 and the battery housing 2 ) and thus to be able to squeeze out the air located in this volume 4 , the traction battery 1 has also figure 2 Air extruder 5 shown in . The air extruder 5 has a vacuum bag 6 and a foam 7 arranged in the vacuum bag 6 . exist figure 2 The air extruder 5 is shown in the final state, in which the inner space of the vacuum bag 6 is filled with air and thus the foam expands. Furthermore, the air extruder 5 can have an initial state in which the inner space of the vacuum bag 6 is at least partially evacuate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com