Manufacturing and assembling method of modular kitchen cabinet

An assembly method and modular technology, applied in the field of commercial sheet metal kitchen cabinets, can solve problems such as increased transportation, storage difficulty, complex overall kitchen cabinet technology, and reduced space utilization, making the production process easier to standardize and less technical requirements. Tall, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

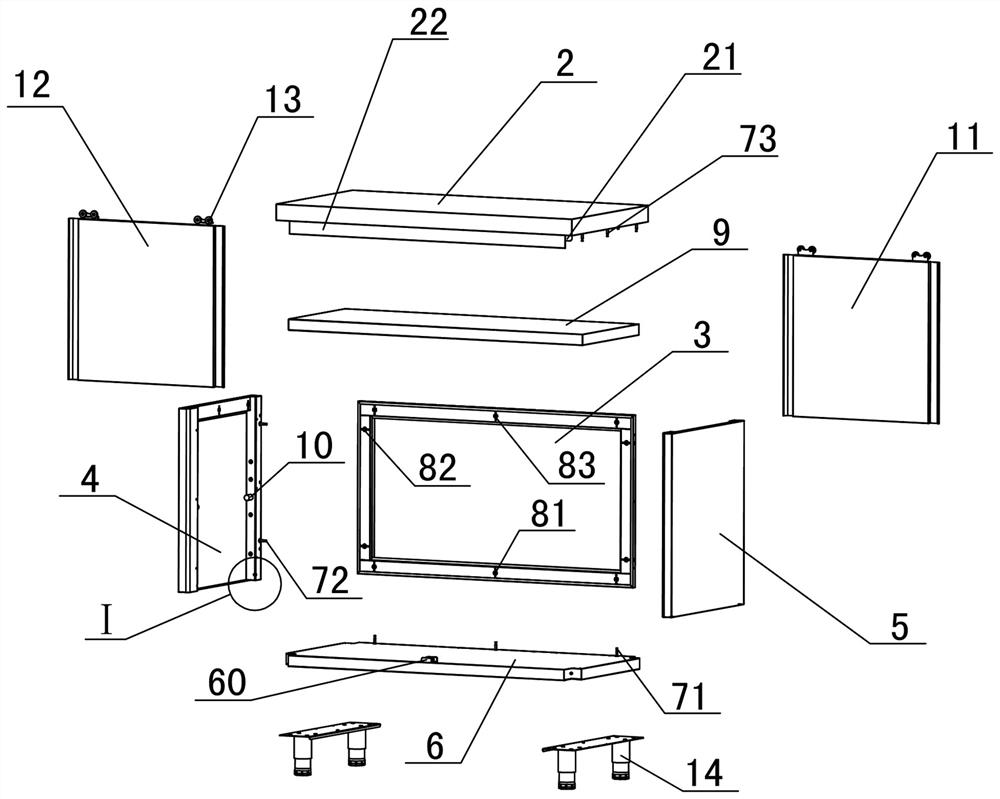

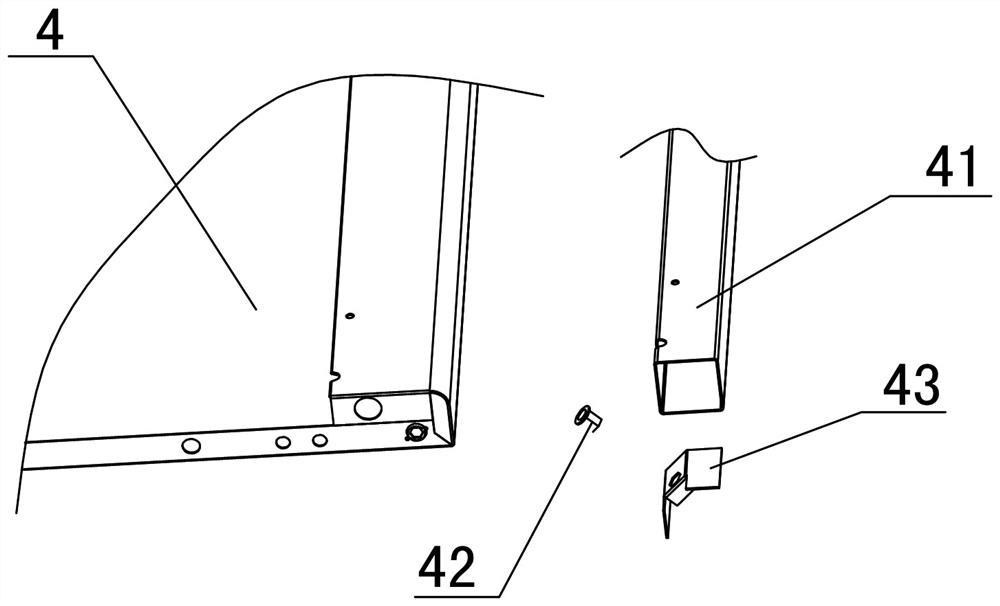

[0029] Below in conjunction with accompanying drawing embodiment, the present invention is further described:

[0030] For unified description and easy understanding, the upper part in this embodiment refers to the natural upper part of the kitchen cabinet in actual use, the lower part refers to the natural lower part of the kitchen cabinet in actual use; the front refers to the side of the kitchen cabinet facing the human body during actual use, and the rear Refers to the side of the kitchen cabinet that is away from the human body during actual use; the inner side refers to the direction toward the interior of the kitchen cabinet, the left side refers to the user's left-hand side when facing the kitchen cabinet, and the right side refers to the user's right-hand side when facing the kitchen cabinet.

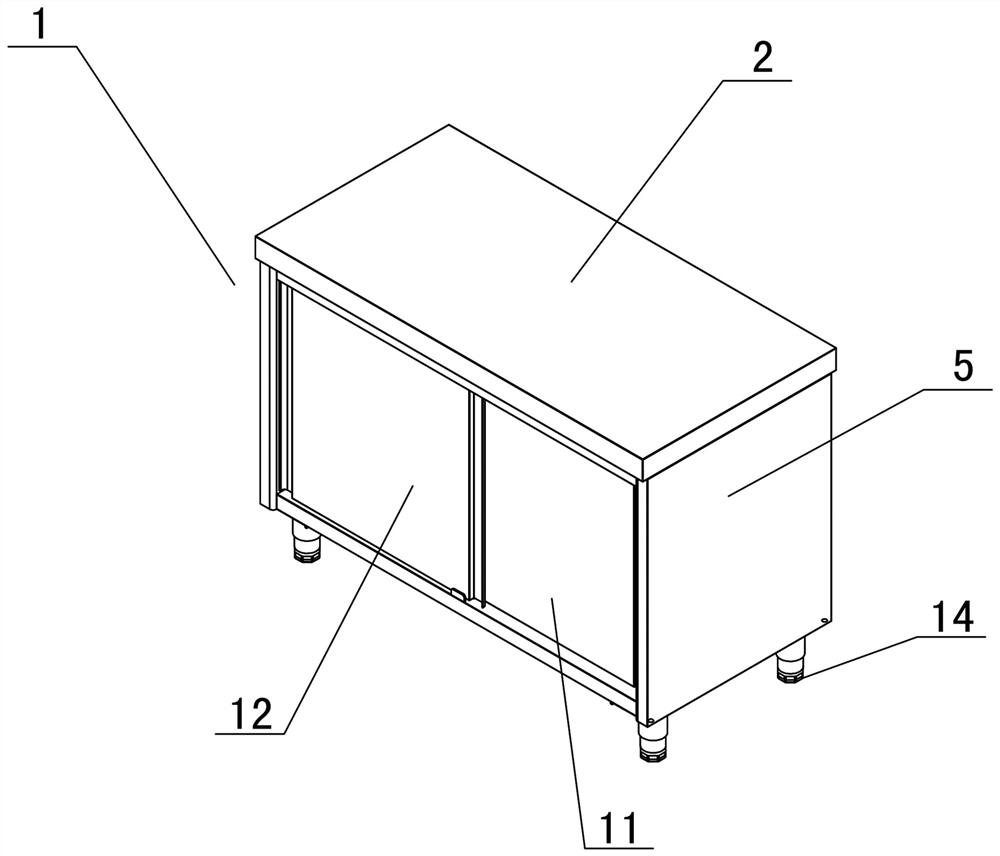

[0031] like figure 1 , figure 2 As shown, the present invention provides a modular kitchen cabinet, including a sheet metal cabinet body 1, the sheet metal cabinet body 1 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com