Profile arcing device

A technology for arc starters and profiles, which is applied in the field of profile processing and can solve problems such as troublesome use and inconvenient fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

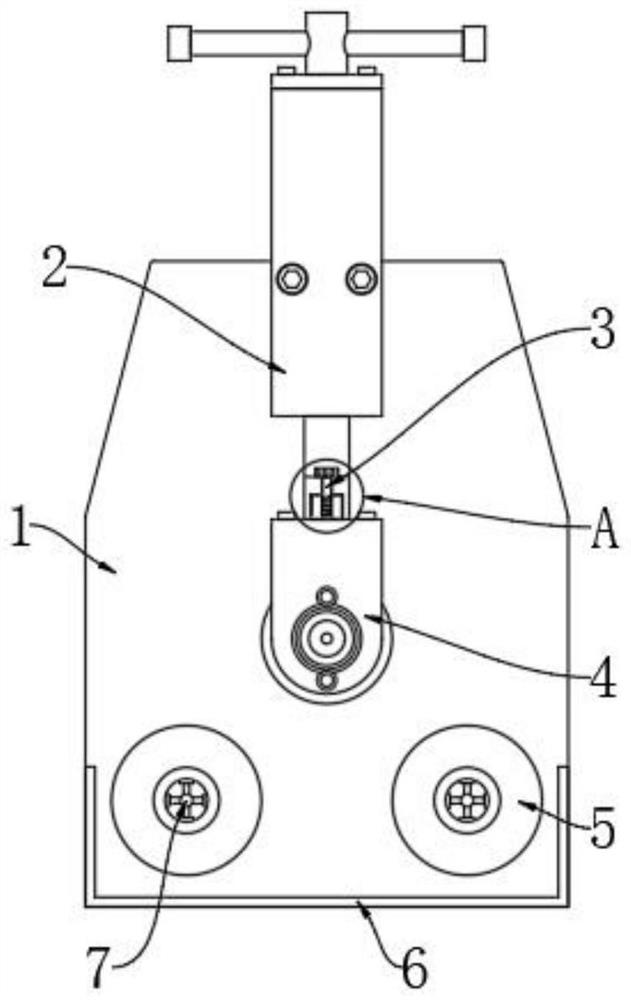

[0030] like figure 1 and Figure 4 As shown, when using this structure, first, the fixing structure 3 includes a fixing bolt 301, a clamping block 302 and a clamping slot 303, the clamping slot 303 is arranged at the bottom end of the inside of the lifting assembly 2, and the clamping block 302 is fixed to the top of the push wheel 4, The inside of the clamping block 302 is threadedly connected with a fixing bolt 301. The outer diameter of the clamping block 302 is smaller than the inner diameter of the clamping slot 303. A clamping structure is formed between the clamping block 302 and the clamping slot 303. Pick up the push wheel 4, and then remove the push wheel 4. The clamping block 302 at the top is aligned with the clamping slot 303, and then the push wheel 4 is pushed upward. At this time, the push wheel 4 pushes the clamping block 302 to insert into the interior of the clamping slot 303, and then the fixing bolt 301 is passed through the lifting assembly The inside of...

Embodiment 2

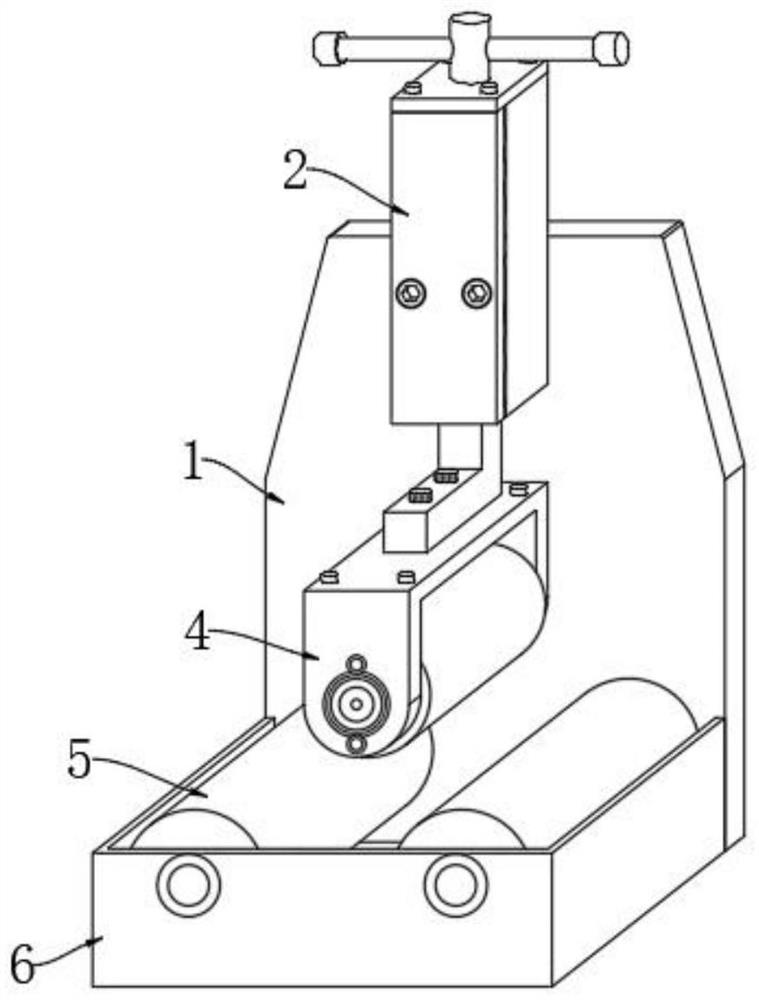

[0032] like figure 1 and Figure 5 As shown, when using this structure, first, the reinforcement structure 7 includes a reinforcement hole 701, a reinforcement rod 702 and a connecting rod 703, the reinforcement hole 701 is provided inside the arc starting roller 5, the reinforcement rod 702 is fixed inside the reinforcement hole 701, and A connecting rod 703 is fixed on one side of the reinforcing rod 702, and several reinforcing rods 702 are arranged. The several reinforcing rods 702 are distributed at equal intervals outside the connecting rod 703. The interior of the reinforced rods 702 can be connected by connecting rods 703 , and the structure formed between the reinforcing rods 702 and the connecting rods 703 can improve the internal strength of the arc starting roller 5 .

Embodiment 3

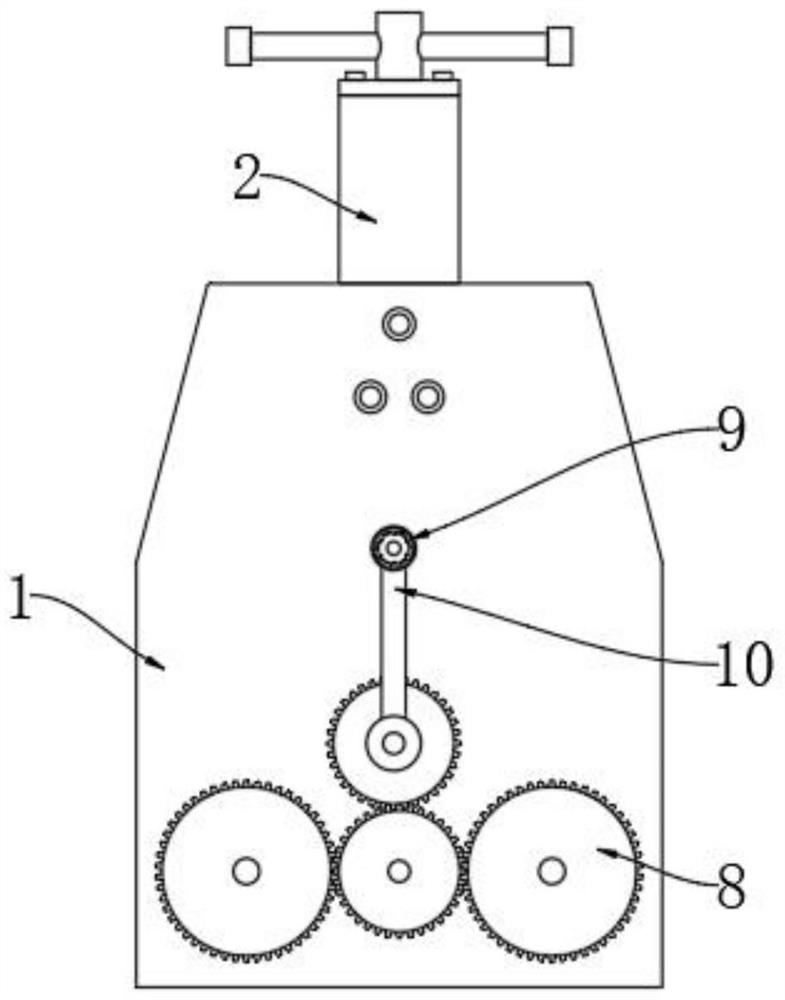

[0034] like image 3 and Image 6 As shown, when using this structure, first, the protective structure 9 includes a protective cover 901, an adaptive cotton 902, a fixing block 903 and a fixing groove 904. Self-adaptive cotton 902, a fixing block 903 is fixed inside the protective cover 901, a fixing groove 904 is arranged inside the rocker arm 10, and several fixing blocks 903 are arranged. The cover 901 can prevent the rocker arm 10 from slipping, and the adaptive cotton 902 inside the protective cover 901 can be automatically deformed according to the shape of the user's hand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com