AGV jacking trolley

A small car and jacking technology, which is applied in the direction of motor vehicles, electric vehicles, vehicle parts, etc., can solve the problems of poor mobility, single structure and function of AGV cars, and inability to move in all directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

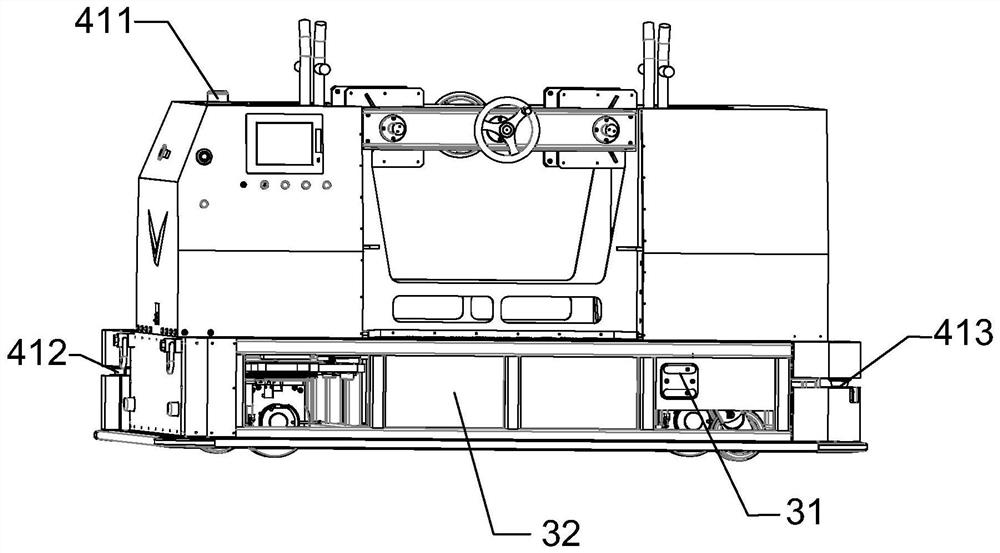

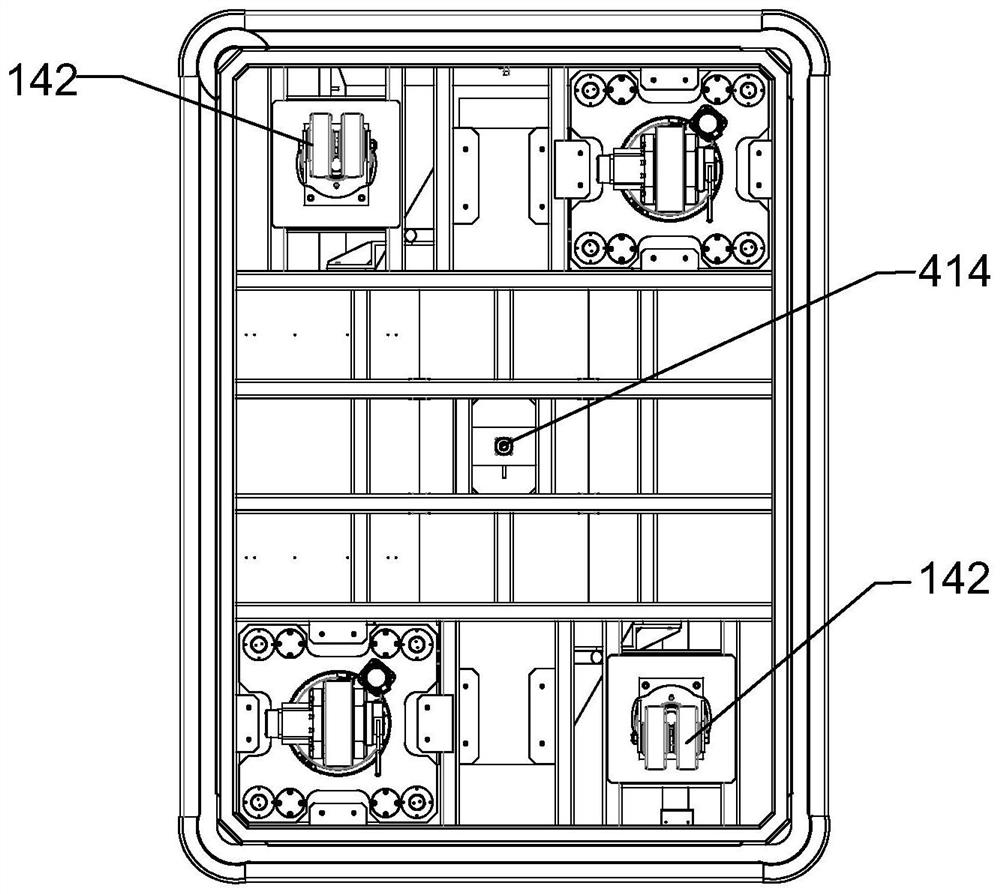

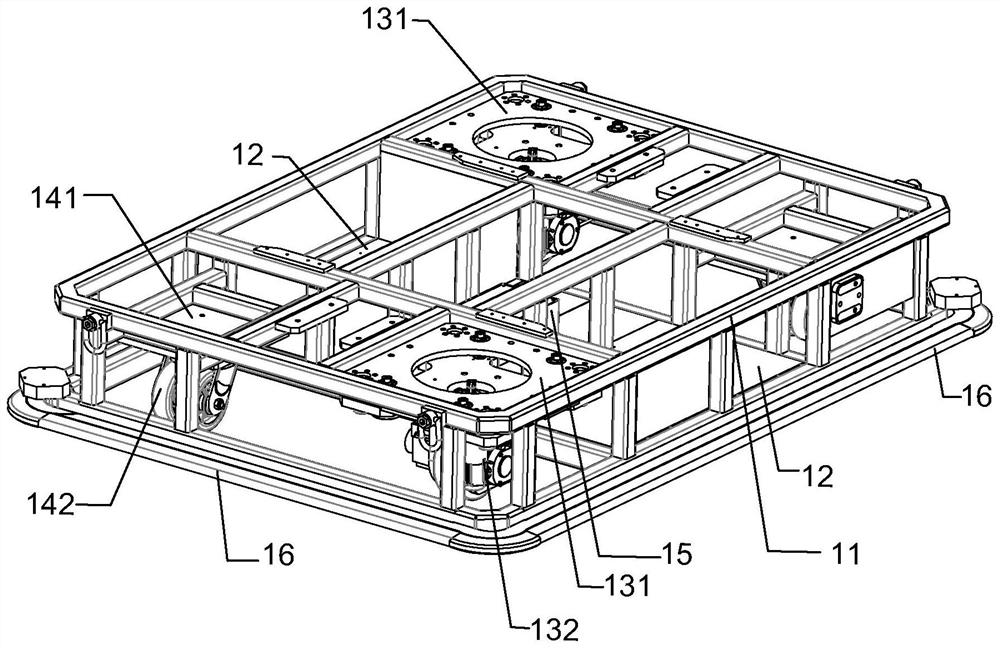

[0057] see Figure 1 to Figure 8, An AGV jacking trolley according to an embodiment of the present invention includes a vehicle body, a chassis 11, a handling device, a charging system and a control system. The chassis 11 includes a frame, a bottom plate 12 and a running device, and the frame is arranged at the bottom of the vehicle body. The bottom plate 12 is provided at the bottom end of the vehicle frame for installing electrical components. The traveling device is installed at the bottom of the frame, and includes a traveling drive device and a universal wheel device respectively corresponding to two diagonal positions of the frame. The handling device includes two sets of hoisting blocks 21 and two sets of locking devices, and the two sets of hoisting blocks 21 are oppositely arranged above the vehicle frame along one of the length or width directions of the vehicle frame. The two sets of lock devices are arranged opposite and spaced above the frame along the other dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com