Seamless ice sleeve spinning equipment with full-automatic plaiting switching function and spinning method of seamless ice sleeve spinning equipment

A kind of textile equipment, fully automatic technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problems of automatic textile seamless clothing, single equipment structure, poor structural connection and coordination, etc., and achieve high reliability Operability and controllability, simple processing steps, orderly effect of plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments.

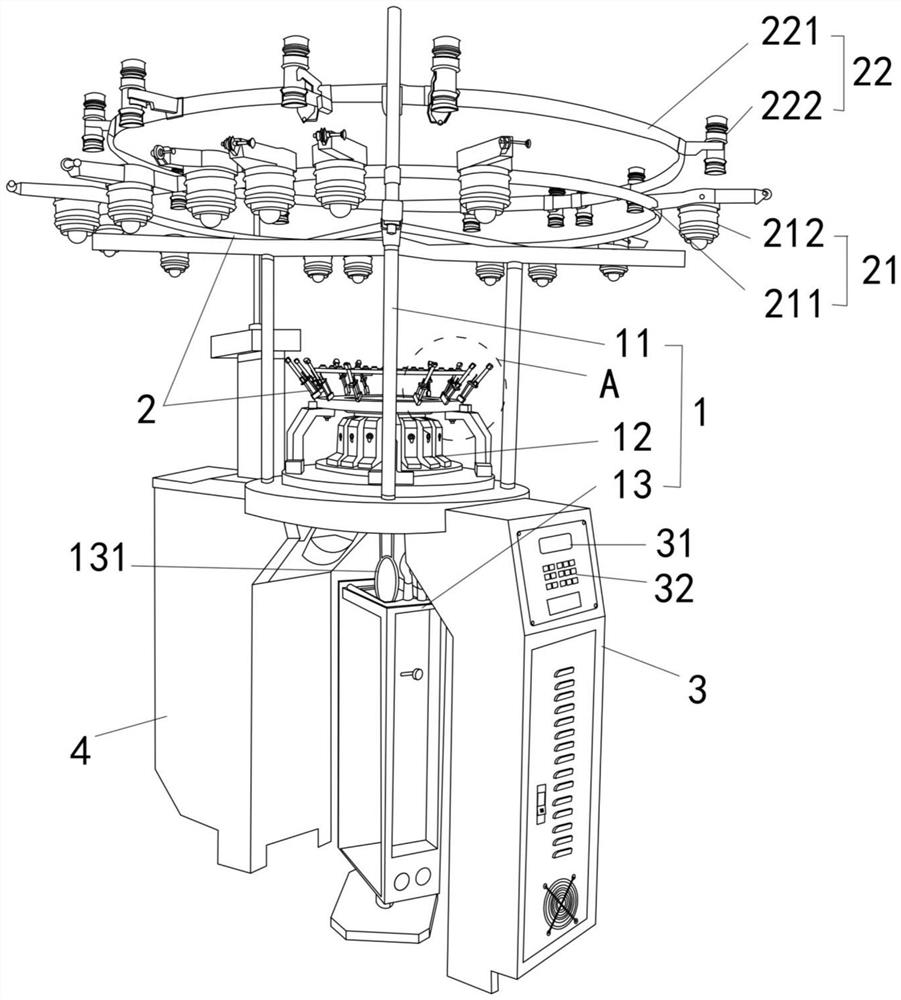

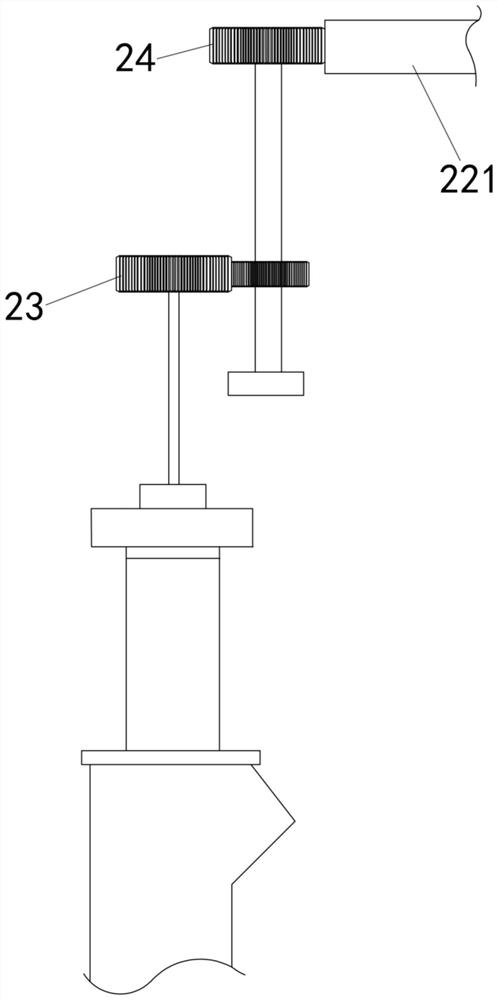

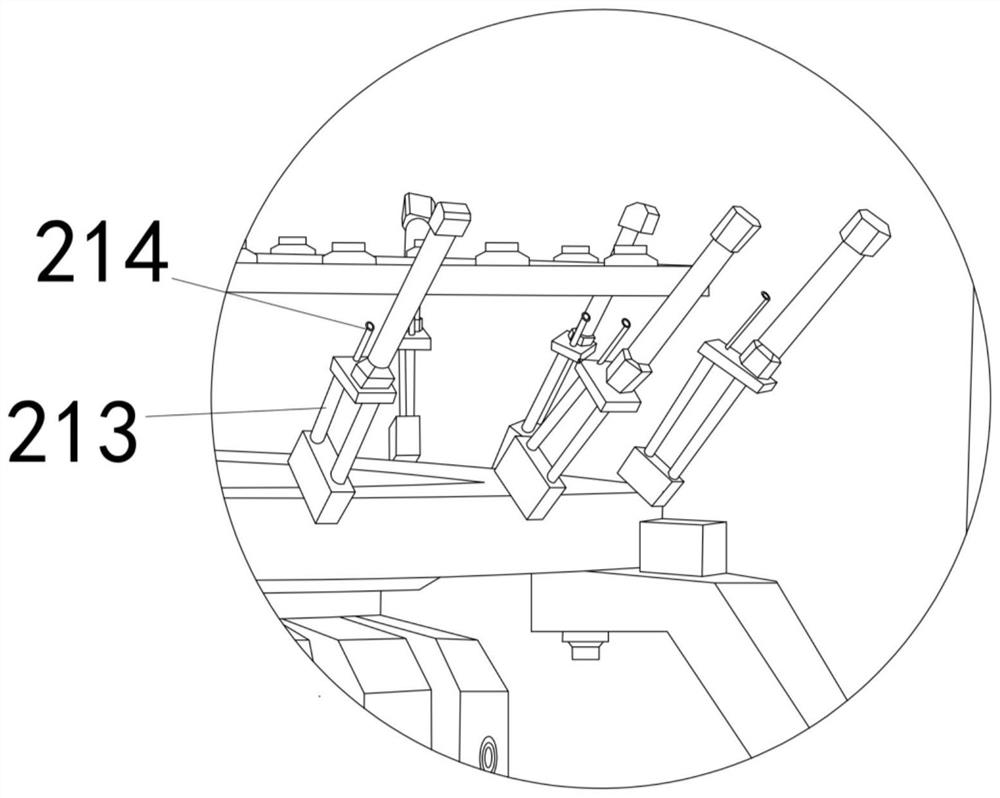

[0030] like Figure 1-4 As shown, the present invention is a seamless ice sleeve textile equipment with automatic switching plating, including a textile machine and a console, the textile machine includes a textile mechanism 1 and a self-switching plating mechanism 2, and the console includes a front console 3 and a rear console Console 4, the front console 3 is connected with the rear console 4; the textile mechanism 1 includes a central shaft 11, the self-switching plating mechanism 2 is annularly arranged on the outside of the textile mechanism 1, the self-switching plating mechanism 2 and the yarn to be woven Line connection, the front console 3 is respectively connected with the textile mechanism 1 and the self-switching plating mechanism 2; the self-switching plating mechanism 2 includes the first spinning frame 21 and the second roving frame 22, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com