Equal-thickness mortar smearing device for aerated bricks on construction site and construction method thereof

A construction site, aerated brick technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of uneven thickness of mortar applied to aerated bricks, unstable project quality, and project rework, etc., to achieve convenient standardization Construction, improve construction quality, reduce the effect of rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

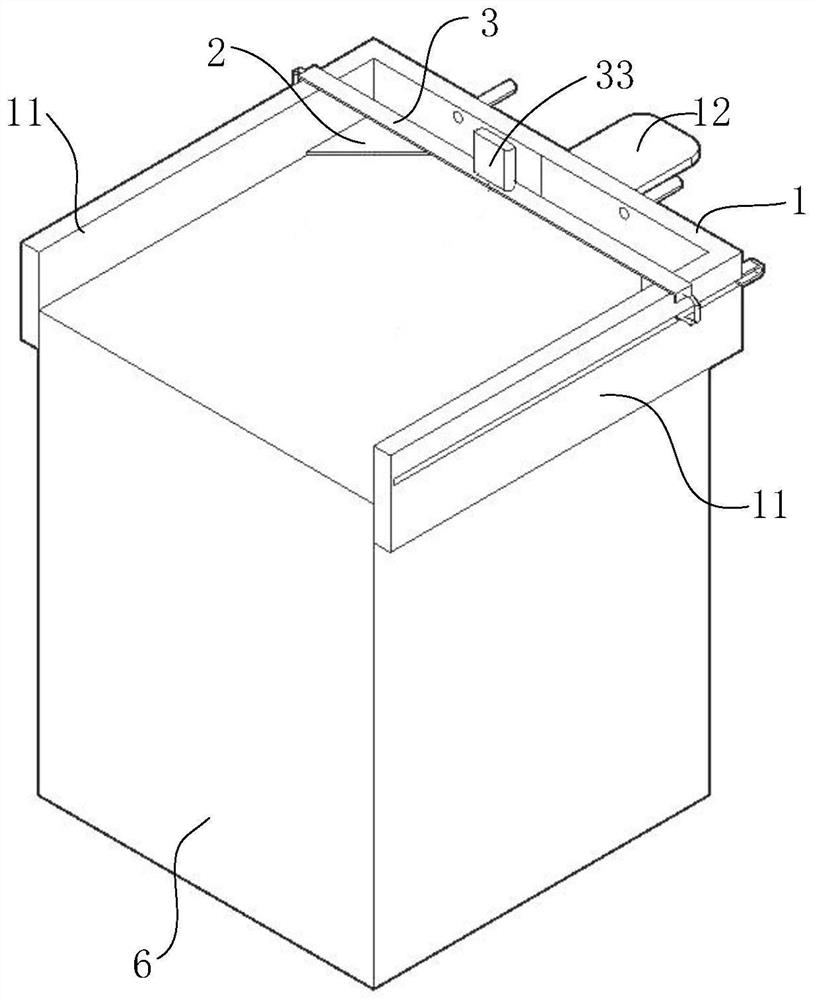

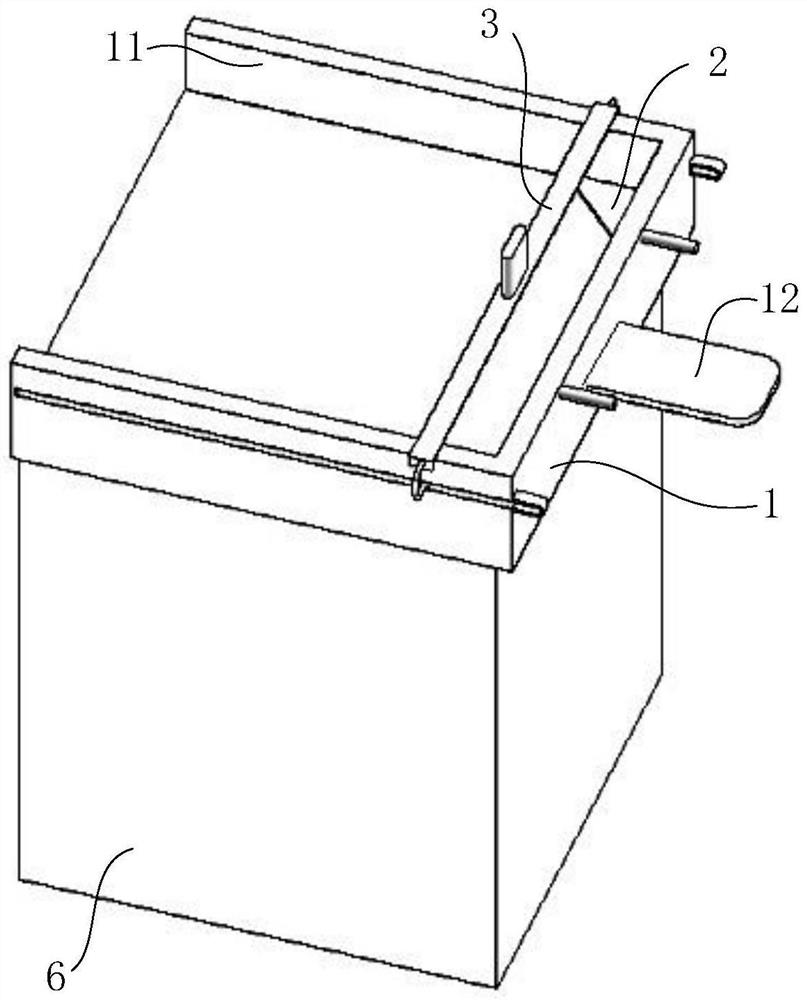

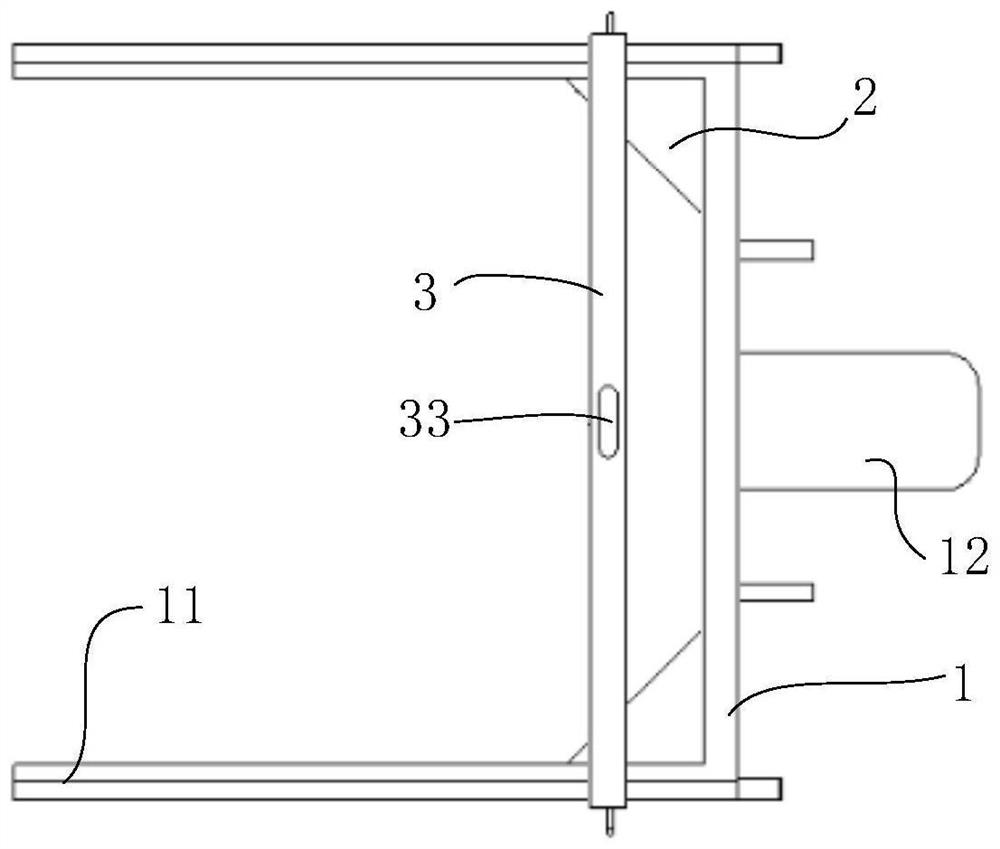

[0034] refer to Figure 1 to Figure 5 As shown, the present invention provides a mortar applicator with equal thickness for air-entrained bricks on a construction site, comprising: a support plate 1 , a limit insert 2 , and a plastering plate 3 .

[0035] Among them, in the present invention, the air-entrained bricks are air-entrained concrete blocks. The support plate can be a plate made of steel, plastic or the like.

[0036] Specifically, two elastic clamping plates 11 are connected to one side of the support plate 1 . The two elastic clamping plates 11 are used to clamp the opposite sides of the grout surface of the air-entrained brick 6 , so that a accommodating space with a gap on one side is formed between the two elastic clamping plates, the grout surface and the inner side of the support plate. After the equivalent elastic clamping plates are clamped on the opposite sides of the coating surface, the construction personnel pour the mortar into the accommodating space...

no. 2 example

[0052] refer to Figures 6 to 8 As shown, the present invention provides a mortar applicator with equal thickness for air-entrained bricks on a construction site. The sheet is movably mounted on the support plate, and also includes an end plate and a driving mechanism. Among them, the structure of the mortar applicator for construction site air-entrained bricks and other thicknesses of the present embodiment is the same as that of the first embodiment, which will not be repeated here.

[0053] Specifically, the mortar coating device for construction site air-entrained bricks and other thicknesses of the present embodiment includes: a support plate 1, a limit insert 2, a plastering plate 3, and also includes a distance away from the place for resting on the grout surface. The end sealing plate 4 on one side of the limiting insert 2 .

[0054] see Image 6 , the position of the end sealing plate 4 is adjustable and installed between the ends of the two elastic clamping plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com